What Is A Glaze In Ceramics?

A glaze is a thin coating applied to the surface of pottery, usually ceramic ware, that serves both decorative and functional purposes. Glazes provide pottery with a glassy, non-porous surface that makes them impermeable to liquids and resistant to scratching (Ceramic glaze).

The main functions of ceramic glazes are to decorate or add color, make pottery impermeable to liquids, strengthen pottery, and protect the clay body from water absorption (The History of Ceramic Glaze). Glazes have been used in ceramic arts and crafts for thousands of years to give pottery a more finished look and improve its functional properties.

Types of Glazes

There are several common types of glazes used in ceramic arts:

Underglaze – Underglaze is applied to greenware or bisque and covered with a transparent overglaze after firing. It allows the natural color of the clay body to show through while adding color and design. Underglazes come in a wide variety of colors.

According to this article, underglazes are often used in combination with other glazes for unique effects.

Overglaze – Overglaze is a glaze applied on top of an already fired ceramic piece. Overglazes adhere to the piece without needing to refire the clay body. Overglazes come in various finishes like gloss, satin, matte, or crystalline.

According to this video overview, overglazes are often used for decorative elements like adding color, patterns, or accents over an existing glazed surface.

Slip Glazes – Slip glazes are made from a clay body thinned with water. They can be used as a base glaze or layered for multicolored effects. Slip glazes enhance the natural color and texture of the clay body. Popular versions include white slip, black slip, and red slip glazes.

According to this article, slip glazes blend and move during firing for natural, rustic effects.

Glaze Ingredients

Glazes are made up of four main ingredients: clay, silica, fluxes, and colorants.1 Clay acts as a binder to hold the glaze components together and provide body. The most common clay used in glazes is kaolin. Silica, usually in the form of quartz, makes up the glassy phase of the glaze and provides gloss and hardness. Common sources of silica include quartz, flint, feldspar, and sand. Fluxes are ingredients that lower the melting point of the glaze so it can fuse onto the clay body at kiln temperatures. Common fluxes include soda ash, potash, borax, and lead. Finally, colorants like metal oxides are added to introduce color to the glaze. Common colorants include cobalt (blue), copper (green/blue), iron (brown/green), and manganese (purple).

The ingredients must be combined in the proper ratios to create a stable melting glaze. Glaze chemists carefully formulate recipes to achieve the desired aesthetic effects. Small changes in the proportions of ingredients can significantly impact the glaze’s appearance and properties when fired.2

Glaze Chemistry

The chemistry of how a glaze works is complex, but can be summarized as the interaction between the ingredients during firing that allows the formation of glass to happen at high temperatures. The main ingredients are silica, fluxes, and stabilizers. Silica forms the glass structure, fluxes lower the melting temperature so glaze vitrifies at kiln temperatures, and stabilizers help the glaze melt and form an even layer.1

When clay and glaze are fired together, the ingredients interact through dissolution, suspension, and chemical reactions. The fluxes dissolve the silica, creating a fluid melt. Other ingredients remain suspended in the glass. As firing continues, the melt flows evenly over the clay body, then recrystallizes as it cools, forming a smooth, translucent surface.2

Glazes can also suspend colorants like metal oxides and stains, which remain distinct phases within the glass and provide color. The final appearance results from how the light interacts with the microstructure of the glass and particles within it.3 Understanding how ingredients interact during firing allows ceramic artists to systematically formulate glazes with desired colors, textures, and effects.

Glaze Textures

Glazes can be formulated to produce different textures on the finished ceramic surface. Some common glaze textures include:

Smooth

Smooth glazes have an even, glossy surface without visible irregularities. They are achieved by balancing the ingredients to flow smoothly and evenly over the clay body during firing. Smooth glazes tend to accentuate the form and are commonly seen on porcelain tableware.

Crackled

Crackle glazes intentionally form a network of small cracks across the surface during cooling after firing. This is achieved by layering two incompatible glazes or by adding certain oxides to increase thermal expansion. The cracks reveal glimpses of the underlying clay color. Crackled glazes add visual interest and an aged, antique look.Source

Pebbled

Pebbled glazes have a bumpy texture like orange peel. This effect occurs when certain materials are added to make the glaze viscosity inconsistent, causing thick and thin areas during firing. Pebbling may also result from application techniques like sponge painting. The spotted texture provides visual and tactile interest.

Matte

Matte glazes lack the glossy surface sheen of typical glazes. They have a soft, velvety finish that absorbs and diffuses light. Matte effects are achieved by increasing aluminum, magnesium, and zinc oxides in the glaze recipe. Matte glazes highlight form and contours without reflective highlights.

Glossy

Glossy glazes have a shiny, smooth, reflective surface finish. This occurs when the glaze melts and flows perfectly smooth during firing. High gloss comes from balanced glaze ingredients and a glassy microstructure. Glossy glazes enhance surface decorations and show off intricate details.

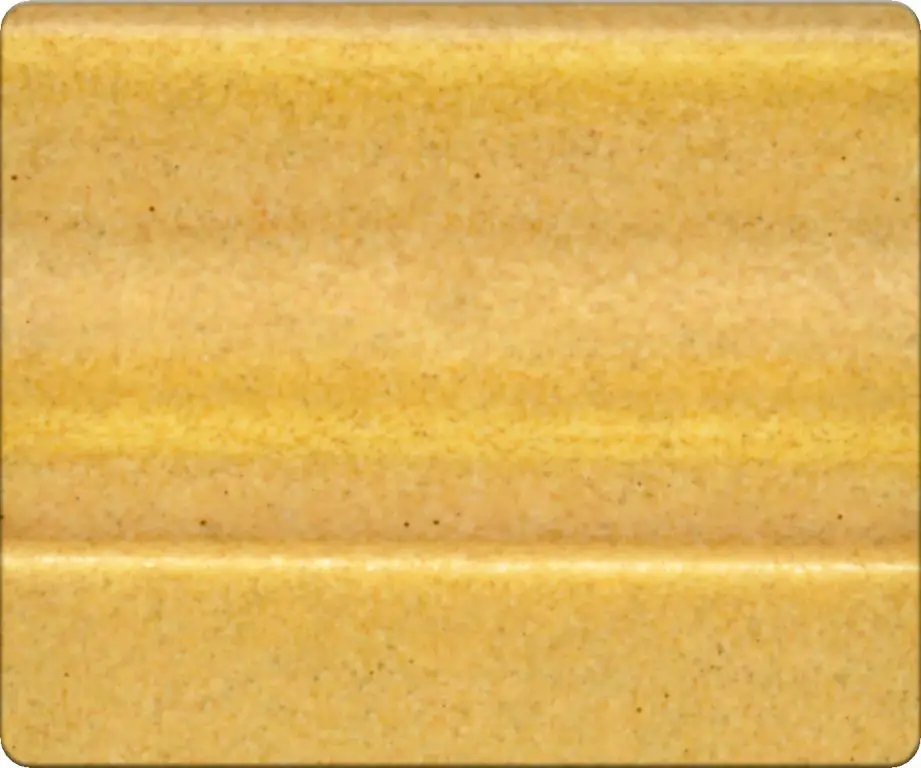

Glaze Colors

Glaze colors can be created from natural ingredients, underglazes, and stains. Various metal oxides and mineral pigments create different glaze colors when fired, such as cobalt oxide for blue, iron oxide for rusty orange and red, copper oxide for turquoise and green, and manganese dioxide for purple.

Natural clay materials like dolomite and talc also influence glaze color. When mixed into the glaze recipe, these materials impart their own subtle hues. Underglazes applied under a clear glaze allow for a full spectrum of colors. Ceramic stains painted on bisqueware can create vivid designs that show through transparent glazes.

By varying the type and amount of colorants, glaze chemistry, and firing temperatures, ceramic artists can achieve a diverse palette of glaze colors on their finished pieces.

Glaze Application

There are several techniques for applying glaze to ceramic pieces:

Brushing

Brushing glaze onto ceramics is a common technique. It allows for precise control over where the glaze is applied. A soft bristle brush is recommended to prevent glaze scratching. Brushes should be high quality and dedicated for glaze use only. Specialized glaze brushes are available for both large and detailed glaze application.

Dipping

Dipping involves submerging the bisqueware piece into a container of liquid glaze. This coats the entire piece evenly. Care should be taken to avoid uneven pooling of glaze in crevices. Pieces are drained and excess glaze is poured back into the container after dipping.

Pouring

Pouring glaze directly onto a piece allows gravity to pull the glaze over the form evenly. This technique requires a thicker glaze consistency. It is important to hold the piece still while pouring to prevent uneven buildup.

Spraying

Spraying glaze with an airbrush or spray gun allows for quick, even coverage. This technique is useful for covering large surfaces efficiently. Care should be taken to avoid overspray. Proper spraying technique is important to prevent uneven glaze thickness.

Glaze Defects

Glazes can develop defects during the firing process that negatively affect the appearance and durability of the finished piece. Some common glaze defects include crawling, crazing, blistering, and pinholing.

Crawling occurs when the glaze pulls away from the clay body and forms ridges, leaving bare areas. It is often caused by poor adhesion between the glaze and clay, an overly thick glaze application, or contamination of the glaze from dust or oils. Proper clay preparation, mixing compatible glazes, and applying an even coat can help prevent crawling [1].

Crazing is a network of fine cracks in the glaze surface. It results from the glaze and clay body expanding and contracting at different rates during firing. Using a glaze compatible with the clay body, proper firing, and adding silica can help minimize crazing [2].

Blistering occurs when gases are trapped between the glaze and clay body, creating dome-shaped protrusions. It can be caused by under-fired glazes, excessive fluxes in the glaze recipe, or impurities in the clay. Adjusting the firing schedule and glaze ingredients can prevent blisters [3].

Pinholing manifests as tiny unglazed punctures in the surface. It results from trapped gases escaping through the glaze during firing. Using a mesh strainer when mixing glazes, applying thinner coats, and slowly increasing kiln temperature can minimize pinholes.

Glaze Safety

Proper safety precautions should always be taken when working with ceramic glazes, as many glaze ingredients contain toxic materials. Glazes often contain heavy metals like lead, cadmium, and barium, which can be dangerous through ingestion, inhalation, or skin contact. Ensuring proper studio ventilation through exhaust hoods and dust masks is crucial. According to the Tumblr post by rainbowsnakes, glazes containing lead, cadmium, copper, zinc, antimony, barium, lithium and manganese can be unsafe for fish tanks or reptile enclosures if the glaze is not properly fired and sealed [1]. Proper firing helps vitrify the glaze into a sealed, non-toxic surface. Always check ingredient safety data sheets and follow manufacturer precautions. Clean up any glaze spills instead of letting dust accumulate. Use gloves and wash hands after use. Following basic studio safety for ventilation, cleaning, and personal protection is important with any ceramic glaze.

Conclusion

In summary, glazes are an essential component of ceramic art. They serve both decorative and functional purposes by providing color, texture, and protection for ceramic wares. Glazes have a long history dating back thousands of years to early human civilizations. The ingredients, chemistry, and techniques for glaze application have evolved over time, allowing artists to achieve diverse aesthetic effects. While glazing can be complex, mastery of the process enables ceramic artists to produce stunning works that withstand the test of time. Glazes transform humble clay into objects of timeless beauty and value. Their continuing popularity speaks to the human appetite for color, brilliance, and durable design in our everyday lives.