What Is The Difference Between Montmorillonite Clay And Bentonite Clay?

Clay minerals are naturally occurring aluminum and magnesium phyllosilicates that play an important role in many industrial applications due to their chemical structures and unique properties. The two most common and commercially used clays are montmorillonite and bentonite, which have some similarities but also key differences that affect their usage.

Montmorillonite is known for its high cation exchange capacity and ability to absorb large amounts of water, making it useful for many applications like drilling mud, foundry sand binding, and cat litter (1). Bentonite also has good absorption properties and is a key ingredient in products like cement, cosmetics, and pharmaceuticals.

While both clays share some chemical similarities, their structure and composition create differences in properties that make each more suitable for certain applications. This article will explore the key chemical, structural, and performance differences between montmorillonite and bentonite clays.

(1) https://www.intechopen.com/chapters/76780

Definition of Clays

Clays are phyllosilicate minerals made up of fine particles. They are formed over long periods by chemical weathering of rocks like feldspar and granite. The weathering process breaks down the rocks into finer grains, eventually reaching particle sizes of less than 2 micrometers. At this size, the particles exhibit plasticity when mixed with water, allowing clays to be shaped and molded.

Clays have a crystalline structure of stacked sheets or layers. The main building blocks of these layered structures are silicon tetrahedra and aluminum octahedra. The sheets are held together by weak chemical bonds, which allow water and other molecules to enter between the layers, giving clays their plasticity. There are many different types of clays, but all consist fundamentally of extremely small, layered mineral particles.

Montmorillonite Clay

Montmorillonite is part of the smectite group of clays and is formed from the weathering of volcanic ash (https://en.wikipedia.org/wiki/Montmorillonite). It has a layered structure with water molecules and exchangeable cations between the layers, allowing it to swell significantly when hydrated. The large surface area and high cation exchange capacity of montmorillonite make it useful for adsorption, catalytic reactions, and stabilization applications (https://www.sciencedirect.com/topics/materials-science/montmorillonite).

The chemical formula for the main layer component of montmorillonite is (Na,Ca)0.33(Al,Mg)2(Si4O10)(OH)2·nH2O. The substitution of Mg for Al in the layers gives montmorillonite its charge deficiency and ability to attract cations (https://www.intechopen.com/chapters/61845). This charge deficiency allows montmorillonite to swell up to 15 times its original volume upon hydration as water molecules and cations enter between the layers.

Bentonite Clay

Bentonite clay is also part of the smectite group and is primarily composed of the mineral montmorillonite (https://en.wikipedia.org/wiki/Bentonite). Like montmorillonite clay, bentonite clay is formed from the weathering of volcanic ash. The weathering process transforms volcanic ash into montmorillonite by breaking the volcanic glass down through hydration and dissolving the nutrients (https://uwaterloo.ca/earth-sciences-museum/resources/detailed-rocks-and-minerals-articles/bentonite-clay). As a result, bentonite clay comprises over 50% montmorillonite and up to 80-90% in its purest form (https://www.sciencedirect.com/topics/earth-and-planetary-sciences/bentonite). The weathering process that forms bentonite clay also gives it a high concentration of trace minerals like calcium, magnesium, and iron.

Chemical Composition

Both montmorillonite and bentonite clay are made of alumina and silica. However, their chemical formulas differ slightly:

Montmorillonite has the chemical formula (Na,Ca)0.33(Al,Mg)2(Si4O10)(OH)2•nH2O. It is a smectite group aluminosilicate mineral containing aluminum and magnesium.

Bentonite has the chemical formula Al2O34SiO2H2O (Na,Ca)0.33(Al,Mg)2(Si4O10)(OH)2•nH2O. It is composed mostly of montmorillonite. The main constituent, which is the determinant mineral, is montmorillonite clay. Bentonite also has small amounts of feldspar, cristobalite, and quartz.

So in summary, both clays share the base montmorillonite mineral structure but bentonite contains some additional minerals. The key difference lies in the cation exchange capacity (CEC), which measures the ability to absorb positively charged ions. Montmorillonite has a higher CEC than bentonite.

Sources:

Difference Between,

The Clay Cure

Structure and Properties

Both montmorillonite and bentonite clay have a layered structure consisting of silica tetrahedral sheets layered between alumina octahedral sheets. When hydrated, water can enter between these layers, causing the clay to swell. This swelling ability allows the clays to absorb water and organic molecules.

However, montmorillonite has a greater swelling capacity and higher specific surface area compared to bentonite clay. Montmorillonite can swell up to 15 times its original volume, whereas bentonite swells up to 12 times its dry volume. The specific surface area of montmorillonite ranges from 650-800 m2/g, while bentonite has a surface area around 200-400 m2/g.

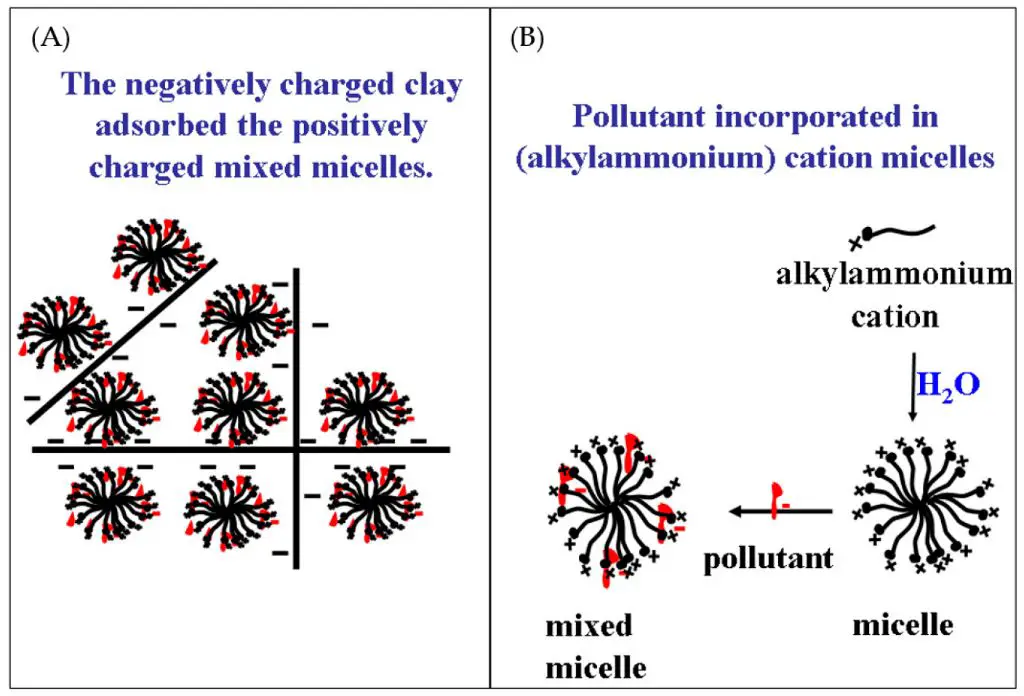

The higher surface area and swelling ability of montmorillonite make it more effective for adsorbing ions, molecules and interacting with polymers to form nanocomposites. Bentonite has lower adsorption capacity but offers higher green strength and plasticity which makes it suitable for binding, pelletizing and sealing.

Uses

Both montmorillonite and bentonite clays have a wide variety of uses due to their ability to absorb liquids and adhere to other substances. However, there are some differences in their specific applications:

As absorbents, montmorillonite is commonly used for cat litter, oil and grease removal, wastewater treatment, and spill containment. Bentonite is used more for animal feed pelletizing, iron ore pelletizing, and litter due to its swelling properties (1).

For drilling mud, bentonite is favored for its gel and thixotropic properties which provide excellent borehole stability. Montmorillonite can be used but requires specific activation treatment (2).

In cosmetics, bentonite is commonly used for its absorbent properties in masks and creams. Montmorillonite is gaining usage for its adsorptive and coloring properties (3).

Overall, bentonite’s swelling ability gives it an advantage for binding, clumping and thickening properties. Montmorillonite’s high cation exchange capacity makes it better suited for adsorbing liquids, odors and toxins.

Availability

Montmorillonite clay deposits are more rare compared to bentonite clay. The major deposits of montmorillonite are found in regions of Wyoming in the United States and in several places across Europe like Bavaria in Germany and Upper Austria. Montmorillonite can also be found in smaller quantities across Asia and Africa.

Bentonite clay on the other hand is found abundantly across the world. There are large reserves located in Greece, Italy, Ukraine, Russia, India, Morocco, and Cyprus. Significant bentonite deposits can also be found in South Africa, Australia, and North America including Wyoming and Montana in the US. Overall, bentonite is considered more common and accessible compared to the rarer montmorillonite clay deposits.

Sources:

https://www.differencebetween.com/what-is-the-difference-between-bentonite-and-montmorillonite-clay/

https://www.theclaycure.co.uk/bentonite-or-montmorillonite/

Pricing

When comparing bentonite clay and montmorillonite clay, bentonite clay is typically the less expensive option. According to Statista, the average price for bentonite clay in 2023 was around $99 per ton. Meanwhile, montmorillonite clay can cost upwards of $150-200 per ton depending on the grade.

Bentonite clay is available in food, pharmaceutical, and industrial grades at varying price points. Food grade bentonite runs $5-25 per pound, while pharmaceutical grade is $15-40 per pound. Industrial bentonite is the least expensive at $60-120 per ton when purchased in bulk.

Montmorillonite also comes in different grades, with prices ranging from $100 per ton for lower grade industrial uses to over $200 per ton for ultra fine montmorillonite for high end industrial applications. Cosmetic grade montmorillonite can cost $150-300 per kg.

Overall, bentonite clay provides a more affordable option compared to montmorillonite for most applications. However, for specific uses where a high purity montmorillonite clay is required, buyers may opt for montmorillonite despite the higher costs.

Conclusion

Montmorillonite and bentonite clay have some key similarities. They are both clay minerals with a layered sheet structure and high swelling capacity when exposed to water. However, there are also important differences between the two.

Montmorillonite refers specifically to the clay mineral with a chemical composition containing aluminum, magnesium, and silicate. Bentonite is a broader term referring to a group of clays predominantly made up of montmorillonite. While some bentonite is almost entirely montmorillonite, other types of bentonite contain additional clay minerals such as kaolinite.

The two types of clay also have slightly different properties, with bentonite typically having higher swelling capacity, plasticity, and viscosity compared to montmorillonite clay. Bentonite usually requires activation to reach its full thickening potential. Montmorillonite can be used on its own.

When choosing between the two, bentonite is preferred for applications requiring high viscosity and absorption. Montmorillonite is suitable where a moderate amount of swelling is needed. Cost and availabilty in your region may also help determine the best choice.

Overall, bentonite and montmorillonite have more similarities than differences. But knowing the unique properties and composition of each allows selecting the right clay for your needs.