What Are The Properties Of Clay In Pottery?

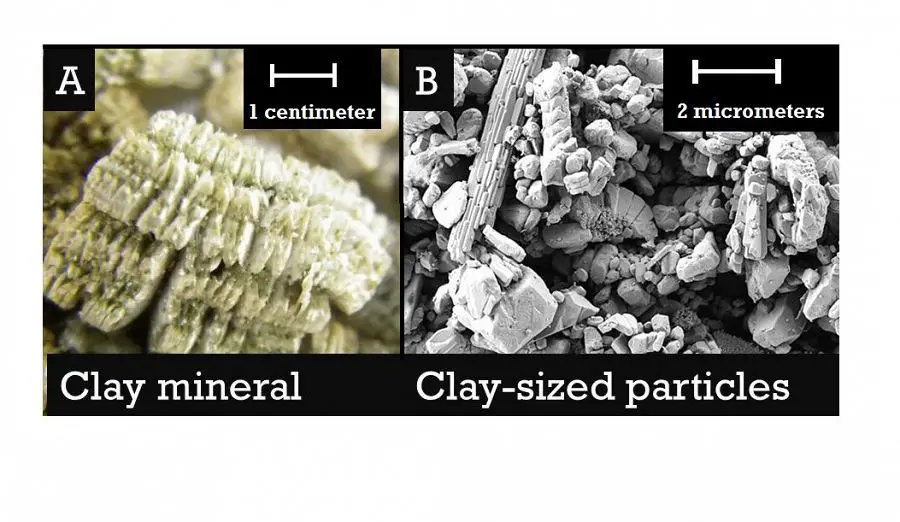

Clay is a type of fine-grained natural soil material containing particles less than 0.002 mm in size. Clays develop plasticity when mixed with a limited amount of water, which allows them to be molded into shapes that retain their form when dry. There are many different types of clay, but the most common include kaolinite, montmorillonite-smectite, illite, and chlorite.

Clay consists primarily of phyllosilicate minerals, which contain variable amounts of water trapped in the mineral structure. The water content and mineral composition determine the clay’s plasticity, hardness, shrinkage, porosity, color, and texture when worked into a finished ceramic piece. When fired at high temperatures in a kiln, the clay undergoes chemical and physical changes that permanently harden it into a ceramic material.

Due to its abundance, versatility, and useful properties, clay has been an integral material for pottery and ceramics throughout human history, dating back to the earliest civilizations. Understanding the characteristics of clay is key knowledge for potters and ceramicists seeking to create high quality fired wares.

Sources:

https://en.wikipedia.org/wiki/Clay

https://www.sciencelearn.org.nz/resources/1771-what-is-clay

Composition

Clay’s primary chemical components are clay minerals, silica, and alumina. Clay minerals are hydrous aluminum phyllosilicates that contain variable amounts of water trapped in the mineral structure. The most common clay minerals include kaolinite, montmorillonite-smectite, illite, and chlorite.

Silica is silicon dioxide (SiO2) and is the primary constituent of sand. In clay, silica particles are smaller than 0.002 mm in diameter, allowing them to remain suspended in water. The specific surface area of silica particles gives clay its plasticity.

Alumina refers to aluminum oxide (Al2O3). The amount of alumina affects clay’s refractoriness or ability to withstand high temperatures. Clays with high alumina can withstand higher firing temperatures before vitrifying.

The percentages of these components vary based on the clay’s composition and properties. For example, kaolin clay contains mainly kaolinite mineral plus quartz and other impurities, while Ball clay has high kaolinite and varying amounts of mica, feldspar, and quartz. Composition determines the clay’s suitability for different uses.

Source: Clay mineral | Definition, Structure, Composition, Uses …

Plasticity

Plasticity refers to the ability of clay to be molded and hold its shape [1]. When clay is mixed with water, it becomes soft and pliable. This allows it to be shaped into various forms and retain those shapes without cracking or crumbling [2].

The plasticity of clay depends on several factors like the size and shape of the clay particles, the amount of water added, and presence of any additives. Clays with smaller, platelet-shaped particles tend to be more plastic. Adding water lubricates the particles allowing them to slide over each other when molded. However, too much water will make the clay muddy and unable to hold its shape well.

An optimal level of plasticity is crucial in pottery-making. Highly plastic clay is easily shaped into intricate forms. As it dries and fired, it retains details better. However, non-plastic clay is difficult to work and prone to cracking and warping. Knowing the right techniques to reach ideal plasticity for a clay body is an important skill for potters [3].

Firing Process

Clay undergoes two main firing stages – bisque firing and glaze firing. Bisque firing is the first firing stage and it happens at a lower temperature, usually between 1100-1200°F. Bisque firing hardens the clay body and makes it less porous and absorbent in preparation for glazing. During bisque firing, chemical water and carbon dioxide is driven off from the clay. This causes the clay to shrink slightly. Bisque ware is unglazed and porous after the initial bisque fire.

Glaze firing is the second firing stage at a higher temperature, usually between 2200-2300°F. The glaze melts during this firing stage and forms a glassy coating that adheres to the bisque clay surface. Glaze firing can cause additional shrinkage. The glaze makes the final ware non-porous, harder, more durable, and water-resistant. Different glazes require specific firing temperatures and schedules for proper maturation and results. Cooling the kiln slowly after firing is also an important step.

Proper bisque and glaze firing are essential processes in creating high quality ceramic pottery. The firing schedule, ramp up and down rates, and peak temperatures are carefully controlled according to the clay body composition and glaze chemistry. More information on firing techniques can be found at https://www.soulceramics.com/pages/bisque-firing-guide.

Shrinkage

One of the most important properties of clay is how much it shrinks during the drying and firing processes. As clay loses water, its dimensions change. During drying, clay shrinks approximately 5-8%, and during firing, clay will shrink an additional 4-15%, depending on the clay body composition (Clay Shrinkage During Drying and Firing | Preventing Defects). Firing shrinkage is a good indicator of how vitrified or glass-like a clay body becomes at high temperatures – the more it shrinks, the more vitrification has occurred (Firing Shrinkage). Understanding and anticipating shrinkage is critical for potters to create functional ware and achieve their desired sizes and forms.

Porosity

Clay is a porous material, meaning it has small holes and openings throughout its structure that allow water and air to pass through (Clay Body Porosity). The porosity of clay is an important property that affects its ability to absorb water. When clay is fired, its porosity decreases as the material vitrifies and densifies. However, most ceramic clays maintain some level of porosity after firing.

The porosity and permeability of clay allow it to readily absorb water when immersed or exposed to moisture. This is beneficial when using clay to make flower pots, allowing the clay to retain some water for plant roots. However, excess porosity can make clay prone to cracking and breakage, especially when exposed to freezing temperatures (Are Clay Pots porous and have good water absorption?).

A balance must be struck between absorbency and strength when formulating clay bodies for pottery. Using clay with moderate porosity results in pieces that are permeable enough to absorb some moisture but also sturdy enough for functional use.

Color

The natural color of clay depends on the minerals present in the clay body. Common clay colors include white, cream, red, brown, and gray. The iron oxide content heavily influences the fired color. More iron oxide leads to warmer red and brown tones. Clays low in iron fire to lighter buff or white colors.

Ceramic stains, also called mason stains, are commonly used to introduce color effects. These stains are made of metal oxides, sulfides, and other compounds that influence the fired color of the clay body. Popular stain colors include greens, blues, blacks, browns, yellows, and reds. Applying stains to the raw unfired clay enables the color to permeate the clay body during firing. Manufacturers such as Mason Color Works offer a wide range of stains in liquid, powder, and crayon formats.

The final fired color depends on the clay body, any stains, the firing temperature, and the kiln atmosphere. Oxidation firing typically yields brighter colors than reduction firing. Certain colors can only be achieved in specific atmospheres. Testing and experience are needed to predict the final result of colored clays.

Sources:

Texture

The texture of clay can range from smooth to gritty depending on the composition and preparation. Polymer clays often start with a gritty texture out of the package that needs to be conditioned to make it smooth. Kneading and rolling the clay will help blend the particles together and eliminate grittiness. Using a pasta machine or acrylic roller can further smooth the clay into an even sheet (source).

For air dry clays like paperclay, the surface can be smoothed using wet sandpaper or sanding sponges starting with a medium grit and moving to a finer grit. A silicon sculpting tool can also help smooth and blend the texture (source). Isopropyl alcohol applied with a brush or cloth is another technique for smoothing the surface of polymer or air dry clays (source).

Strength

The strength and durability of clay depends on several factors including the composition, thickness, and firing process. Air-dry clays can be prone to fragility and breakage if made too thin. According to Adelepo, air-dry clay should be made at least 1 cm (0.4 inches) thick to improve sturdiness. Thicker walls when sculpting larger pieces also prevent fragility (

The composition of the clay body affects strength as well. Porcelains tend to have less dry strength compared to stoneware bodies containing ball clay. Air-dry polymer clays are also slightly more brittle than clays designed for firing, as noted by Susie Benes (

Conclusions

The properties of clay are vitally important in its use for pottery. Clay’s composition, plasticity, firing process, shrinkage, porosity, color, and texture can be summarized as the key characteristics that make it well-suited for pottery and ceramics. Clay’s chemical makeup with silicates, alumina, and other minerals grant it malleability when wet and hardness when fired. Its ability to be shaped while wet but hold its form when dried makes clay an ideal material. Clay shrinks during the firing process as its water evaporates, resulting in hardened, durable ceramic items. The porosity of clay after firing allows air permeability and can affect strength and appearance. Different clay composition and firing methods impact the final color and texture of pottery. Understanding how these properties work together gives potters control over the clay and enables the creation of functional and beautiful objects. In summary, the flexibility while wet but rigidity when fired, along with effects on porosity, shrinkage, color, and texture make the properties of clay essential knowledge for pottery and ceramic work.