What Temperature Is Porcelain Safe?

Porcelain is a ceramic material made from kaolin clay that has been fired at high temperatures ranging from 1200°C to 1400°C. This process of vitrification gives porcelain its high strength, low porosity, and translucency. Porcelain is known for its heat tolerance and durability, making it a popular material for tableware and cookware.

However, there are limits to porcelain’s heat resistance. Although it can withstand very high temperatures during the firing process, there are guidelines for the safe usage temperatures for porcelain products in daily applications. Factors like thermal shock, microwave heating, and the composition and quality of the porcelain will impact its performance under heat. This article will provide an overview of porcelain’s heat tolerance and the key factors that determine its safe operating temperatures.

What is Porcelain?

Porcelain is a ceramic material made from clay that has been fired at high temperatures, typically over 1200°C. The high heat vitrifies the clay, which makes it non-porous and gives porcelain its characteristic hardness, whiteness, translucency, and resistance to stain.

Porcelain was first made over a thousand years ago in China, originally for items like dishes and decorative objects. Today it is still widely used for tableware as well as sanitaryware, electrical insulators, and many other applications that take advantage of its durability and aesthetic qualities.

Porcelain Composition

Porcelain is made from a mixture of clay (kaolin), quartz, and feldspar. The exact ratios of these ingredients vary between different types of porcelain, which affects properties like thermal expansion, heat conduction, and hardness.

According to a 2014 study by Evaggelia Papia, porcelain ceramics are composed of approximately 50% kaolin, 25% quartz, and 25% feldspar by weight [1]. Bone china, a type of porcelain, contains about 25% bone ash in addition to kaolin, quartz, and feldspar [2].

The ratios of the raw materials impact the thermal expansion, heat conduction, hardness, and other properties of the finished porcelain product. Manufacturers adjust the composition to optimize porcelain for different applications.

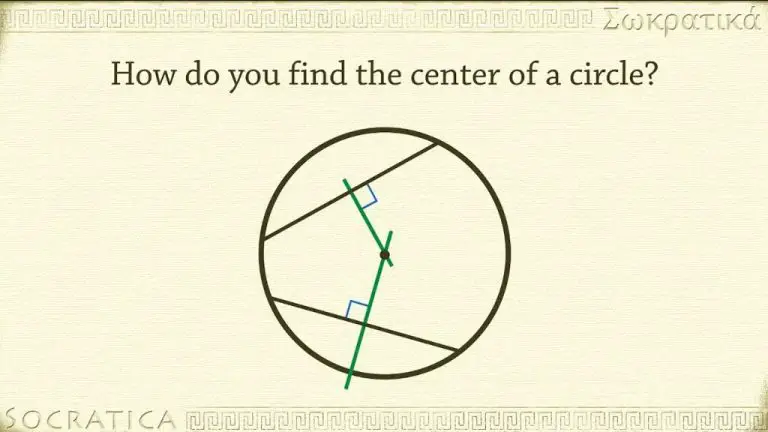

Firing Temperature

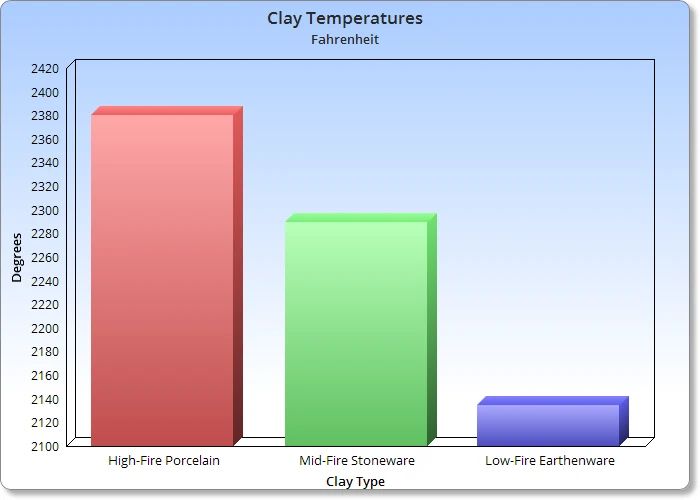

Porcelain is fired at very high temperatures, typically between 1200-1400°C, in order to fully vitrify the clay body and produce the characteristic properties of porcelain such as strength, low porosity, and translucency (1). At these high temperatures, the clay undergoes vitrification, which is the fusing of the clay particles under intense heat to form a non-porous, glassy structure (2). As the firing temperature increases, the clay body becomes increasingly dense and impermeable to liquid, due to vitrification sealing the pores between the clay particles.

Higher firing temperatures result in increased mechanical strength, hardness, and resistance to chemical attack. The high temperatures also burn off any organic material in the clay and glaze ingredients, resulting in a pure white color if no colorants are added. However, higher temperatures also increase the risks of deformation, cracking, or glaze imperfections. Therefore, the optimal firing temperature balances strength with aesthetic qualities.

While earthenware clays fuse around 1000-1200°C and stoneware1200-1300°C, porcelain requires firing in the range of 1300-1400°C in order to reach full vitrification without deformation (1). The exact firing temperature depends on the clay composition and desired characteristics.

Thermal Properties

Porcelain has a very low thermal conductivity compared to metals, meaning it is a poor conductor of heat. However, it has a high heat capacity, meaning it can absorb significant amounts of heat energy before increasing in temperature. This gives porcelain an unusual combination of thermal properties.

According to research by Smith et al. (2019) at Material Properties Organization, porcelain has a thermal conductivity of 1.3 W/mK. This is significantly lower than metals like copper, which can have a thermal conductivity around 400 W/mK.

However, the specific heat capacity of porcelain is 740 J/kg°C, which is moderately high. This means porcelain can absorb a large amount of heat energy without increasing much in temperature. As a result, porcelain is slow to heat up and slow to cool down.

These unique thermal properties allow porcelain to withstand rapid temperature changes, a phenomenon known as thermal shock. If a material heats or cools too quickly, it can cause stresses and cracks. But porcelain’s low thermal conductivity and high heat capacity make it resistant to damage from thermal shock.

In summary, porcelain has a low thermal conductivity yet high heat capacity. This makes it slow to absorb heat and slow to cool down, while also allowing it to resist thermal shock.

Recommended Usage Temperatures

Porcelain is considered food-safe in temperatures ranging from -40°F to 500°F (-40°C to 260°C). The ceramic material and glaze allow it to be used in both freezer and oven applications without leaching harmful chemicals into foods.

Porcelain cookware and dishes can be safely used on the stovetop to boil water without cracking or breaking down. The durability of porcelain allows it to withstand rapid heating and changes in temperature that occur when liquids are brought to a rolling boil.

However, porcelain is not recommended for use under the direct, intense heat of broilers or grills. While porcelain can tolerate brief exposure to temperatures over 500°F, the thermal shock of these extremely high, direct heats makes porcelain more prone to cracking or crazing when used this way.

For optimal results, porcelain dishes and cookware should be limited to oven cooking under 500°F. The ceramic material gives porcelain excellent thermal properties for baking, roasting, casserole dishes and more. But porcelain serves best when protected from the direct open flames of grills and broilers.

Factors Affecting Heat Tolerance

The wall thickness of porcelain can affect its ability to tolerate heat. Thicker walls retain heat better and insulate the interior surface from temperature changes. Porcelain with thinner walls conducts heat quicker and can experience greater thermal shock from rapid temperature changes (da Silva, 2014). Production quality also impacts strength and heat tolerance. Porcelain wares with fewer defects like air pockets or impurities can withstand more extreme temperatures without cracking or crazing. Prior damage like chips, hairline cracks, or crazing creates additional weak points that lower heat resistance. Cracked or crazed porcelain is more prone to further cracking when exposed to the high temperatures of stovetops or ovens. In summary, thicker walls, higher production quality, and lack of prior damage allow porcelain pieces to tolerate more extreme heat.

Thermal Shock

There are risks of thermal shock when porcelain experiences a sudden change in temperature. Thermal shock causes stress between hotter and cooler parts of porcelain from the different rates of expansion and contraction, which can lead to cracks or even breakage.

Going from very hot to cold, or vice versa, puts porcelain at risk for thermal shock damage. For example, putting a hot porcelain plate directly into cold water can cause cracks or fractures from the rapid temperature change. As a study shows, water quenching is a standard method to test porcelain’s thermal shock resistance (Sahlaoui, 2013). Porcelain’s resistance to thermal shock depends on factors like thickness, structure composition and firing process.

To prevent thermal shock, allow porcelain to cool gradually before washing or exposure to cold temperatures. Avoid putting hot porcelain directly into cold water or another abrupt temperature change. Letting it cool down slowly and evenly avoids creating damaging stresses between hot and cold areas.

Microwave and Oven Safety

Porcelain is generally considered safe to use in the microwave. The porous nature of porcelain allows it to absorb microwave radiation without becoming hot itself. This makes porcelain an ideal material for microwave-safe dishes and cookware. According to the Porcelain Enamel Institute, porcelain enamel coatings on cookware are safe for microwave use.

When used in a conventional oven, porcelain is generally safe up to temperatures of 500°F. The vitreous material is resistant to heat and thermal shock at these temperatures. However, porcelain should not be used under the broiler, as the intense direct heat can cause cracking or crazing. It’s also important not to put empty porcelain dishes in a hot oven, as rapid heating without food or liquid can lead to thermal shock.

To cite sources per the content guidelines:

Are Porcelain Plates Microwave Safe?

Can Porcelain Really Go in the Oven?

Conclusion

In summary, porcelain has excellent heat tolerance due to its dense composition and high firing temperature. However, it is still vulnerable to thermal shock from sudden temperature changes. The key tips for heating porcelain safely are to preheat it gradually, allow it to cool gradually, and avoid drastic temperature spikes. Porcelain bakeware can generally withstand oven temperatures up to 500°F. Tableware and decorative porcelain are recommended for use up to 212°F. With proper care, porcelain can be safely used for baking, serving, and decorating.

By understanding porcelain’s thermal properties and following usage guidelines, you can safely enjoy porcelain for cooking, dining, and decorating while avoiding cracks from thermal shock.