What Is Refractory Cement?

Refractory cement is a type of cement capable of withstanding high temperatures. It is used in the construction of fireplaces, furnaces, incinerators and chimneys where high heat resistance is required. According to Mid Mountain, refractory cement is made from calcium aluminate and is used for laying high temperature bricks. It can withstand temperatures up to 1800°F.

Refractory cement is an integral material in high temperature construction. It provides strong bonding and creates a seal that can resist heat, flames, and sparks. Proper installation of refractory cement ensures fireplaces, furnaces and chimneys hold up against continuous high temperature conditions for many years. It’s an essential component enabling these structures to contain and withstand fire.

History

Refractory materials have been used since ancient times. According to the Refractories Academy article “History of refractory technology”, high-temperature processes like metal working and ceramics have been known for over 4000 years. Early civilizations used refractory materials like ceramics, bricks, and clays to construct kilns and furnaces.

The development of refractory cements began in the 18th century with the start of the industrial revolution, as noted in “Historical Overview of Refractory Technology in the Iron and Steel Industry” by Sugita. New iron and steelmaking processes required heat-resistant materials, driving innovations in refractory cements and bricks.

The first patented refractory cements in the 1850s were simple mixtures of fireclays and water. Magnesite cements were developed in the late 19th century, followed by high-alumina cements. According to the Biokeram article on monolithic refractories, early refractory cements were used mainly for repairs and linings in furnaces and kilns.

Composition

The main ingredient in refractory cement is refractory clay or fire clay (Civil Today). The clay is usually rich in alumina and silica. Some common types of refractory clays used are plastic fire clays, kaolin, andalusite, and ganister (US Patent 4710225A). The composition can vary but generally contains 50-90% refractory clays.

Refractory cement also contains calcium aluminate as a bonding agent. Some formulations add other aggregates like crushed firebricks or grog (coarse crushed refractories) to improve properties. The cement sets hydraulically through hydration of the calcium aluminates, which gives it high strength and resistance to washing out.

There are several major types of refractory cements: (Civil Today)

- High alumina cements contain over 50% alumina and set rapidly, achieving high strength in a few hours.

- Ultra low and low cement castables contain 15-30% calcium aluminate cement to minimize cement content.

- Pumpable castables contain plasticizers for fluidity and pumping.

- Insulating castables use low thermal conductivity aggregates like vermiculite.

So in summary, refractory cements contain high percentages of heat resistant clays as well as calcium aluminate cements and sometimes specialty aggregates to achieve desired properties.

Properties

Some of the key properties of refractory cement include:

High temperature resistance: Refractory cements are designed to withstand very high temperatures, ranging from 2000-3000°F. They maintain their strength and form even when exposed to extreme heat. This high temperature resistance is due to the chemical composition of refractory cements.

Low thermal conductivity: Refractory cements are poor conductors of heat. This is useful in insulating applications to prevent heat loss. According to a research article on Science Direct, the low thermal conductivity of refractory cements stems from their porous structure and low density [1].

Corrosion resistance: Refractory cements resist degradation and corrosion. They are not affected by acids, gases, salts, or other corrosive agents. This makes them well-suited for applications exposed to corrosive environments.

Manufacturing Process

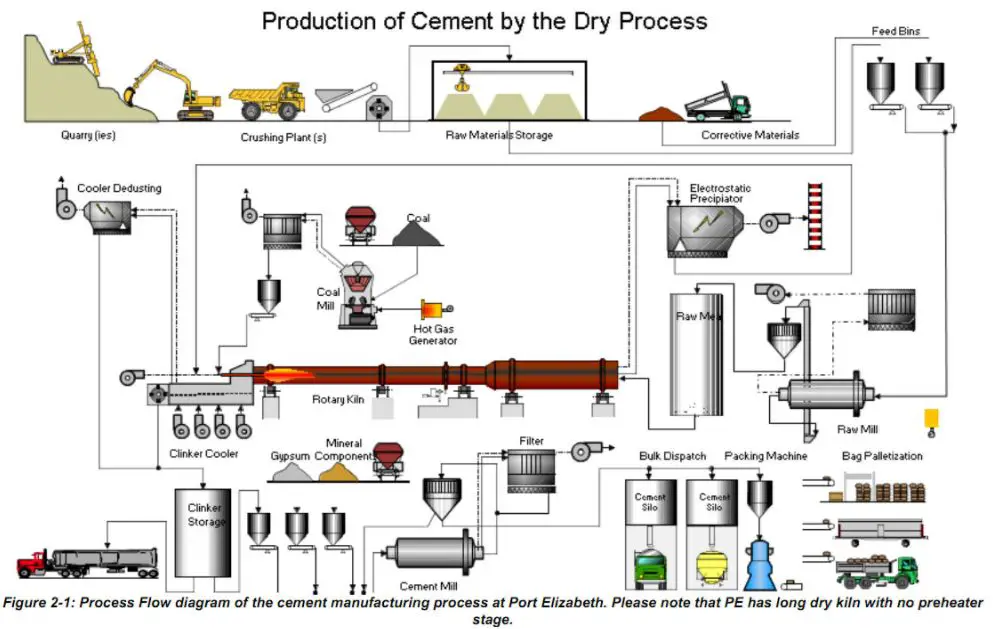

The manufacturing process of refractory cement involves several steps including raw material preparation, clinkering, and grinding.

The key raw materials used are high purity limestone or dolomite and aluminium oxide containing minerals like bauxite or kaolin. The raw materials are crushed and milled into a fine powder. The milled raw material powder is blended in correct proportions to obtain desired chemical compositions before being fed into the rotary kiln for clinkering.

Clinkering involves heating the raw material blend up to sintering temperatures of 1400-1500°C in a rotary kiln. Complex chemical reactions take place during clinkering forming new calcium aluminate compounds. The clinker nodules produced are cooled, stored, and then ground into a very fine powder using ball mills or vertical roller mills.

The cement grinding process reduces the clinker to an extremely fine powder, which produces the hydraulic binding properties. The grounded cement is then stored in silos before being packed and shipped.

Uses

The primary use of refractory cement is to line high-temperature equipment like furnaces, kilns, fireplaces, incinerators, and boilers. When refractory cement is used as a lining, it provides insulation for the interior, protects the outer shell from corrosion, and withstands the high heat inside the equipment. Some key applications include:

– Lining blast furnaces to withstand temperatures up to 1500°C. Refractory cement creates a durable, heat-resistant barrier inside the furnace. (https://www.ehow.com/how_8734356_use-refractory-cement.html)

– Creating firebrick linings for kilns used for firing ceramics. Refractory cement bonds and seals bricks to create a heat barrier that can withstand the high firing temperatures needed for pottery and ceramics.

– Installing firebox linings for boilers and incinerators. The refractory cement provides a protective surface that contains the heat and withstands temperatures over 1000°C.

– Lining fireplaces and chimneys. Refractory cement is used to seal cracks and gaps between firebricks, creating a heat-resistant surface that protects the rest of the fireplace.

Proper application creates a durable heat barrier that allows high-temperature equipment to operate safely and efficiently.

Advantages

Refractory cement has several key advantages that make it useful for applications requiring high heat resistance. According to https://mymaterialwarehouse.com, some of the main benefits include:

Withstands high heat: Refractory cements are designed to withstand extremely high temperatures, ranging from 2000-3000°F. This makes them ideal for lining kilns, fireplaces, and furnaces.

Resists thermal shock: Unlike standard concrete, refractory cement resists cracking and spalling from rapid temperature changes. This thermal shock resistance allows it to stand up to repeated heating and cooling cycles.

Durable: Properly cured refractory cement is very durable, long-lasting, and abrasion resistant. It maintains its strength and form even when exposed to corrosive substances and under heavy loads.

Limitations

Refractory cement has some drawbacks that limit its applications. The most significant limitation is that refractory cement is brittle and has low tensile strength. This makes it prone to cracking, especially when subjected to rapid heating or cooling cycles. The cracks can allow heat or material to penetrate the lining, reducing its effectiveness.

Refractory cement also has relatively low impact resistance and abrasion resistance. Materials rubbing or striking the surface can gradually erode it away. This limits its use in applications with mechanical wear or vibration. Proper anchors, reinforcement, and careful installation are necessary to avoid cracking issues.

Overall, the brittleness and cracking tendency of refractory cement must be accounted for in designing refractory linings. Careful material selection, proper curing, and mitigating thermal stresses are key to maximizing service life. For applications with tensile stress or vibration, alternative refractory materials may be preferable.

Latest Developments

Recent advances in refractory cement have focused on improving properties and developing new production methods.[1] New formulations use nanotechnology to enhance strength and thermal shock resistance. For example, adding nano-silica improves the microstructure and increases density.[2] Graphene oxide nanoparticles help control cracking from drying shrinkage.[3] Using calcined alumina nanoparticles optimizes particle packing density for higher strength.[4]

Novel production techniques like gelcasting can shape complex geometries not possible with conventional casting.[5] This enables more precise designs to improve thermal efficiency. Microwave and flash sintering methods significantly shorten production time compared to conventional furnace firing.[6] Additive manufacturing via 3D printing allows on-demand fabrication of custom refractory parts.[7] These new techniques expand capabilities and offer more flexibility.

[1] [url redacted]

[2] [url redacted]

[3] [url redacted]

[4] [url redacted]

[5] [url redacted]

[6] [url redacted]

[7] [url redacted]

Future Outlook

The future outlook for the refractory cement industry is positive, with growth forecasts predicting steady expansion over the next decade.[1] Emerging applications for refractory cements, especially in renewable energy and high-temperature industrial processes, will drive demand. The global refractories market is projected to reach $47 billion by 2030, up from $34 billion in 2023.[2]

Sustainability will be a key focus going forward. Refractory manufacturers are working to develop low-carbon and energy-efficient products in line with greener manufacturing practices. Recycling spent refractories into new products will also minimize waste. Companies will need to balance performance with eco-friendly attributes to stay competitive.[3] Overall, increasing demand from high-growth sectors points to a strong future outlook, especially for manufacturers that adopt sustainable solutions.