Is Pottery Clay The Same As Ceramic Clay?

Both pottery clay and ceramic clay refer to clay that can be shaped into pottery or ceramic objects and then hardened through firing in a kiln. However, there are some key differences between clays used specifically for pottery versus broader ceramic purposes.

Pottery clay, sometimes referred to as earthenware clay, is clay that can be shaped when wet and then fired to harden it. It tends to be coarser and rougher in texture. Ceramic clay encompasses pottery clay but also includes porcelain and stoneware clays that create smoother, finer ceramics.

Raw Materials

The raw materials used to create pottery clay versus ceramic clay differ. Pottery clay is made purely from clay. Types of clay used for pottery include earthenware clays like red clay, ball clay, and stoneware clay. Ceramic clay incorporates non-clay minerals and materials in addition to clay, such as feldspar, flint, silica, and alumina. The clay composition affects properties like firing temperature, plasticity, porosity and strength.

For example, according to Kiln Frog (https://kilnfrog.com/blogs/frogblog/pottery-vs-ceramics), stoneware clay used for pottery contains more iron and fluxes than the kaolin clay used for porcelain ceramics. The stoneware clay results in more plasticity and lower firing temperatures compared to porcelain clay. Porcelain clay produces a harder, denser and more translucent end product. The clay composition differences stem from the inclusion of non-clay minerals in ceramic clay versus pure clay for pottery.

Plasticity

Plasticity refers to the ability of clay to be shaped and hold its form without cracking or slumping. This is an important property for potters as it determines how easily the clay can be worked and shaped into pottery pieces. Ceramic clays and pottery clays differ significantly in their plasticity.

Pottery clays like stoneware and earthenware tend to be much more plastic and malleable than ceramic clays. According to Digital Fire, stoneware clays exhibit high plasticity which allows potters to throw thinner walls and taller forms without slumping or cracking. In comparison, ceramic clays have lower plasticity which makes throwing more difficult.

The higher plasticity in pottery clays is due to their mineral composition. As explained by Pottery Creative, pottery clays contain kaolinite and illite clays which provide plasticity. Ceramic clays contain more non-plastic materials like feldspar and quartz which reduce plasticity.

The difference in plasticity has implications for how the clays are used. Potters prefer highly plastic clays for throwing on the wheel. Ceramic clays with lower plasticity are often used for casting or handbuilding where flexibility is less important.

Firing Temperature

The firing temperature is one of the key differences between pottery clay and ceramic clay. Pottery clay, also known as earthenware, is fired at lower temperatures, typically between 1,700°F to 2,100°F (900°C and 1,150°C) or Cone 04-06 [1]. Ceramic clay, such as stoneware and porcelain, requires much higher firing temperatures. Stoneware clay is fired between 2,200°F and 2,400°F (1,200°C and 1,315°C), while porcelain requires an even higher temperature between 2,200°F and 2,450°F (1,200°C and 1,343°C) [2].

Shrinkage

Clay shrinks both during the drying process and when fired in a kiln. The amount of shrinkage depends on the type of clay body. According to Lakeside Pottery, different clays can shrink anywhere from 4% up to 15% from the original size. The total shrinkage is cumulative between the drying and firing processes.

As explained on Reddit, clay shrinks some in both the bisque firing and glaze firing stages. The bisque firing shrinkage is usually around 8-12%. The glaze firing causes another 2-3% shrinkage typically. So the total firing shrinkage for a piece from wet clay to finished glazed ware can be 10-15% on average [1].

Porosity

Porosity refers to the tiny holes and spaces within clay that allow air and water to pass through. It is an important characteristic that affects the strength, durability, weight, and firing requirements of clay.

Pottery clays like stoneware and earthenware tend to be more porous, with porosity levels ranging from 15-25%. According to Digitalfire, higher porosity levels indicate lower strength and durability. Porous pottery clays require more careful drying to prevent cracking and warping.

In contrast, ceramic clays like porcelain have lower porosity, usually below 10%. As explained by Big Ceramic Store, low porosity ceramics are denser, stronger, and more waterproof. The compact structure prevents warping and makes ceramic clays suitable for items like dinnerware and tiles.

Understanding the differences in porosity allows potters and ceramicists to select the right clay for their project requirements.

Strength

Porcelain and stoneware clays have greater strength and durability compared to earthenware clays like terracotta. When fired, porcelain becomes vitrified and non-porous, giving it excellent strength against breaking and chipping. According to Fired Strength, ceramics like porcelain perform better under compressive strength testing than when stressed flexurally. Porcelain’s dense vitrified structure makes it very durable and ideal for high-use tableware.

Stoneware, while not quite as strong as porcelain due to a lower firing temperature, still becomes vitrified and achieves good strength when fired. According to Stoneware Clay Vs. Porcelain Clay, stoneware resists chipping, cracking and breaking better than earthenware clays. While not as ideal as porcelain for repeated daily use, stoneware has sufficient strength for most functional pottery uses.

In comparison, lower-fired earthenware clays like terracotta remain porous after firing. This porosity leads to lower strength and makes earthenware more prone to chipping or breaking under stress, as noted by Clay vs Ceramic. For items requiring durability, stoneware and porcelain clays are better choices than earthenware.

Uses

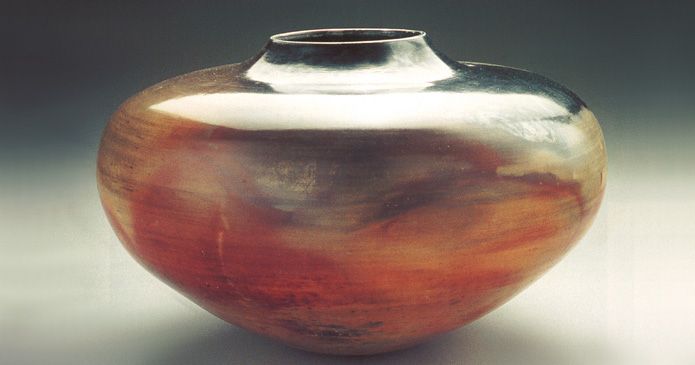

Pottery clay is most commonly used to create functional items such as cups, bowls, vases, and plates. Potters wheel-throw pottery pieces to create these articles [1]. Pottery tends to serve practical purposes and is often glazed or left unglazed. Ceramic clay has more diverse uses including tiles, bricks, pipes, flooring, countertops, and high voltage insulators. Ceramic materials are valued for their hardness and ability to withstand high temperatures. Advanced ceramic engineering enables the production of ceramic parts for rockets, jet engines, and nuclear reactors [2]. While both pottery clay and ceramic clay are used artistically, ceramic clay allows for more intricate sculptural and design work.

Cost

There can be significant cost differences between pottery clay and ceramic clay. According to The Beginning Artist, standard pottery clay costs around $3 per pound on average. However, premium and high quality pottery clays can cost two to three times more, ranging from $6-9 per pound.

Comparatively, ceramic clay is generally more expensive than pottery clay. On Reddit, users report ceramic clay costing around $1.50 per pound on average, while pottery clay averages only $1 per pound. For example, 25 lbs of porcelain ceramic clay may cost $40, while 25 lbs of stoneware pottery clay costs only $25.

The type of clay also impacts cost. As Pottery Crafters notes, a 25 lb bag can range from $15 for lower quality clay to $50 for premium porcelain clays. Glazes and other supplies further add to the cost. Overall, ceramic clays and supplies tend to be pricier than pottery options.

Conclusion

In summary, there are a few key differences between pottery clay and ceramic clay:

– Pottery clay is generally a low-fire clay that vitrifies at lower temperatures, while ceramic clay is a higher-fire clay made for high temperatures and harder vitrification.

– Pottery clay tends to be softer, more porous, and less strong than ceramic clay when fired.

– Ceramic clays are often blended for specific characteristics and uses, while pottery clays are more generic modeling clays.

– Pottery clays are often less expensive and more accessible to hobbyists and artists, while ceramic clays require more specialized knowledge.

– Ceramic clays result in harder, denser products for functional ware, while pottery clays make softer objects like decorative pots and sculptures.

– The different properties like plasticity, shrinkage, and porosity distinguish the best uses for each type of clay.

While there can be overlap, pottery and ceramic clays are tailored for different purposes, temperatures, and applications.