How Do You Make Coloured Slip Clay?

A slip is a suspension of clay in water that can be used to color and decorate ceramic surfaces. Colored slip clay offers a vibrant, beautiful alternative to glazing. By mixing different colorants into a slip, an infinite array of hues can be created.

Making colored slip clay is a straightforward process. First, you’ll choose a clay body and mix it with water to form a pourable slip. Then, add powdered colorants like stains, oxides, or underglazes to tint the slip. The colored slip can be brushed or dipped onto bisqueware or greenware. When fired, it will form a glossy coating while still allowing the texture of the underlying clay to show through.

Working with colored slips has many benefits. Slips can be used to accentuate carved textures. They also allow for vivid colors not always possible with natural clays. Fine details can be painted using colored slip. Compared to glazes, slips bond better to porous bisqueware. For potters looking for more color options, learning to make your own colored slip opens up lots of new decorative possibilities.

Materials Needed

To make colored slip clay, you will need the following materials:

Clay Body

Choose a smooth, plastic clay body that can accept colorants well. Porcelain and white stoneware clays work great for colored slips. Avoid coarse, groggy clay that has lots of texture.

Colorants

Select colorants like ceramic stains, oxides, and underglazes to mix into the slip. Stains tend to give the brightest colors. Oxides and underglazes work too but may mute the color a bit.

Mixing Tools

You’ll need containers for mixing the slip, such as plastic buckets or ceramic mixing bowls. Use a drill with a mixer attachment or rib to blend the slip smoothly and thoroughly.

Basic pottery tools like ribs and sponges can help with slip application later.

Choosing a Clay Body

When making colored slip, it’s best to use a clay body that is smooth, plastic, and relatively fine in texture. This allows the colorants to fully incorporate and results in a vibrant, even color. Some recommended clay bodies for slip include:

- Porcelains – Porcelain is very white in color and creates a blank canvas for adding bright, saturated colors. It has excellent suspension qualities.

- Cone 6 stonewares – Many stonewares are smooth and plastic enough to be used for colored slip. Look for ones without high grog or grit content.

- Cone 04 or 06 casting slips – Manufactured casting slips are formulated for good suspension and fluidity.

In general, it’s best to avoid very coarse, sandy clay bodies as they don’t fully incorporate colorants and can create a speckled look. High grog or grit content can also make a slip hard to apply evenly. Smooth, plastic clays result in the most vibrant and consistent colored slips.

Choosing Colorants

When making colored slip, you have three main options for adding color – metal oxides, ceramic stains, or underglazes. Each has their own characteristics:

Oxides – Oxides are minerals that provide intense, opaque color. They are more difficult to find than stains or underglazes. Oxides mix well together to create secondary colors. Too much oxide can make the slip too thick.

Stains – Stains give transparent, flowing colors. They are widely available and affordable. Stains can be mixed but will mute and dull each other. Too much stain can make the slip too runny.

Underglazes – Underglazes fall between oxides and stains. They give saturated, semi-opaque colors. Underglazes mix well but will also mute each other at high quantities. Too much underglaze can make the slip gloppy.

The intensity of color depends on the concentration of colorant added. Start with a small amount and testApply multiple thin layers for deeper colors instead of one thick layer. Blend complementary colors like blue and orange to create bold secondary colors.

Mixing the Slip

Mixing the colored slip is one of the most important steps in achieving a smooth and consistent application. Pay close attention to adding deflocculants, getting the right consistency, and wedging thoroughly.

Deflocculants are essential for preventing clumping and achieving an even distribution of color. Adding 1-3% of deflocculant by dry weight is recommended. Sodium silicate is a common deflocculant that works well for colored slips. Disperse the deflocculant into the water first before adding the other ingredients.

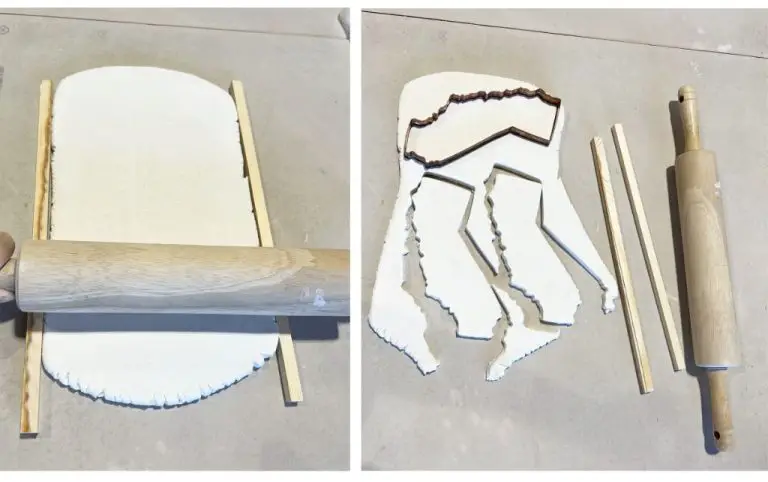

The ideal slip consistency is thick but pourable, similar to a milkshake. Adding too much water will make the slip too thin and runny. Start by mixing the dry ingredients with a small amount of water and then add more slowly until the desired consistency is reached. Test the consistency by dipping a spatula into the mixture and watching how quickly it runs off.

Once the slip is mixed, wedge it thoroughly before use. Wedging blends the ingredients evenly and removes air pockets. Knead and push the clay repeatedly against a clean work surface until it becomes smooth, flexible, and free of lumps.

Applying the Slip

Once your colored slip is mixed, you can apply it to your clay projects in a few different ways:

- Dipping – Fully submerging your clay piece into the slip allows the slip to completely coat the piece. Be sure to tap off any drips before letting it dry.

- Pouring – Slowly pouring the slip over the surface of your clay ensures even coverage. Tilt and rotate your piece to control where the slip flows.

- Brushing – Using a soft bristle brush gives you the most control over where the slip is applied. Brush gently in all directions to prevent brush strokes.

No matter which application method you choose, there are some tips to getting an even coat of slip without excess drips:

- Work on wax paper or plastic sheeting to catch any drips.

- Gently tap off drips from the bottom and sides after coating.

- Allow the piece to sit for a few minutes so drips can level out.

- Use a soft rubber kidney tool to carefully smooth out any thick areas.

Take your time applying the slip and you’ll achieve beautiful even results.

Cleanup and Reuse

After you’re done applying colored slip, you’ll likely have leftover slip as well as tools that need cleaning up. Here are some tips for storing and reusing leftover slip as well as cleaning your slip application tools:

Storing Leftover Colored Slip

Any leftover colored slip can be stored in airtight containers for later use. Slip can usually be stored for up to a few weeks if kept airtight. When storing slip, make sure to label the container with the color and date mixed. Over time, the color may start to separate or fade, so it’s best to use up colored slip within a few weeks if possible.

If the slip starts to thicken up from evaporation, you can add a small amount of water and re-mix to thin it out again. Just be careful not to make it too thin or it may not brush on evenly.

Cleaning Tools

Once you’re done applying colored slip, clean your tools thoroughly to prevent slip from drying on them. Use water to rinse brushes, sponges, and other application tools immediately after use. You may need to gently flex any dried slip off tools. For extra sticky slip, an old toothbrush and warm soapy water can help scrub tools clean.

Let tools dry completely before storing so they’re ready to use for your next colored slip project.

Tips and Tricks

Here are some helpful tips for avoiding issues and achieving the desired effects when working with colored slip:

Troubleshooting Color or Consistency Issues

If your slip is too thin and runny, try adding more clay or a thickener like CMC gum. For slip that’s too thick, add more water slowly. Test the consistency on a piece of scrap clay.

The color may shift after firing, so test samples first. Iron oxide red will turn orange, cobalt blue shifts green. To intensify color, use stains instead of oxide powders.

If the color is uneven or spotty, the pigments may need more mixing time to disperse evenly into the slip. Try mixing for 5-10 more minutes.

Achieving Specific Effects

For flowing colors within the clay, try layering contrasting colored slips next to each other before fusing. The colors will bleed and blend.

Use a slip trailer bottle to apply detailed lines and textures. Try thin layers for translucent effects.

Add mica powders to give a metallic shimmer. Use beeswax resist to maintain crisp edges between colored areas.

Let the piece dry slowly under plastic wrap for crackle effects. Apply layers of different colored slips for multi-dimensional crackle textures.

Firing

Proper firing is essential for creating durable colored slip pieces. It’s important to follow recommended firing schedules and ramp speeds to avoid defects like cracking, bloating, or pinholing.

For colored slip, aim for a final temperature between cone 04 (1945°F / 1063°C) and cone 6 (2232°F / 1222°C). Ramp up at 200-300°F (110-165°C) per hour. A faster ramp can cause cracking or blistering. Hold at top temperature for 10-15 minutes per inch thickness to fully vitrify the clay.

Allow adequate cooling time. Cool at 100°F (55°C) per hour until 1000°F (535°C). Then increase cooling to 200°F (110°C) per hour until room temperature.

After firing, give pieces a final cleanup with a stiff nylon brush to remove any dust or debris. Apply a sealing clear glaze if desired for extra protection and sheen.

Test fire sample tiles first to dial in the ideal firing schedule for your clay body, thickness, and colors. Keep detailed notes each firing for consistency.

Sample Projects

Here are some ideas for decorative projects that showcase colorful slip techniques:

Vases

Tall cylindrical vases look striking with inlaid slip designs. Try thin lines, dots, or geometric patterns around the vase. Layer contrasting colors of slip to create depth. After firing, the vase will have a glossy finish to show off the colors.

Mugs

Mugs are another fun canvas for slip decoration. Paint swirls, stripes, or dots on the outside of a basic mug form. Use a contrasting slip color on the handle or rim for extra interest. Firing will make the mugs food-safe and durable.

Figurines

Sculpt miniature animals, characters, or abstract shapes to decorate with colored slip. Cover the entire piece with one color, or use paintbrush detailing for more color variations. The slip will become part of the surface texture after firing.