What Is The Best Clay For A Tandoor Oven?

A tandoor is a cylindrical clay oven originating from the Indian subcontinent and used to bake flatbreads like naan and roti. Traditionally tandoors were dug into the ground and lined with clay, but modern tandoors are often freestanding. Tandoors can reach high temperatures of up to 480°C (900°F). The heat for a tandoor is traditionally generated by a charcoal or wood fire at the bottom of the oven. Different types of clay have different properties that make them more or less suitable for use in a tandoor oven.

The best clay for a tandoor oven needs to be able to withstand very high temperatures without cracking, conduct heat well for even cooking, have some porosity to allow steam to escape, have good density and low shrinkage, and be resistant to thermal shock. The right clay will result in an effective and durable tandoor oven. This article will examine the critical properties of clay needed for tandoor construction and recommend the ideal clay material.

Heat Resistance

Tandoor ovens reach very high temperatures, typically between 350°F to 900°F (177°C to 482°C). A tandoor expert notes that tandoors can reach temperatures up to 480 °C (900 °F), and they are often kept lit for extended periods (Source). Another source explains that tandoors can exceed 900°F, though most tandoori recipes call for temperatures between 500-600°F (Source).

Therefore, the clay used for tandoor ovens must be able to withstand very high temperatures up to 900°F without cracking or breaking down. The clay needs excellent heat resistance to maintain its structural integrity under the intense heat inside the tandoor over many hours of continuous use.

Thermal Conductivity

Thermal conductivity refers to a material’s ability to conduct heat. When it comes to choosing the best clay for a tandoor oven, you want a material with high thermal conductivity. As explained on Thermtest, clay has the ability to transport heat from the flames to the food inside the oven.

Higher thermal conductivity allows for more even heating within the oven. The clay walls absorb the heat from the fire and distribute it evenly throughout the inside of the tandoor. This allows the food to cook thoroughly without burning. According to research by Foloranmi published on Academic Direct, additives can be used to increase the thermal conductivity of clay. The right clay material with good thermal conductivity is crucial for achieving optimal cooking.

Porousness

One of the most important properties of clay for tandoor ovens is porousness. According to Ancient Cookware, tandoors are traditionally made from high porosity earthenware clay. This allows the clay to absorb moisture from the food inside the oven, creating a steaming effect.

The porous clay acts like a sponge, soaking up juices and moisture released from meat and vegetables as they cook. This steaming action helps keep food tender and moist. More porous clay provides greater absorption and more steaming. Highly porous clay is ideal for tandoor ovens so that foods cook with a juicy, succulent interior.

Density

The density of the clay is an important factor for a tandoor oven. Denser clay retains heat better, which helps maintain high temperatures inside the oven. However, clay that is too dense can prevent steam absorption during cooking. Steam absorption is critical for producing naan and tandoori chicken with a moist, tender interior.

According to research, most tandoor ovens are made from clay with a density between 1.8-2.0 g/cm3. This provides a balance of heat retention while still allowing some steam absorption. Higher density clays like fireclay (2.2-2.6 g/cm3) may retain heat too well. Lower density clays like earthenware (1.5-1.8 g/cm3) may not retain enough heat.1

When selecting clay, it’s ideal to test small samples at different densities to find the optimal balance for heat retention and steam absorption.

Shock Resistance

Shock resistance refers to a clay’s ability to withstand rapid heating and cooling cycles without cracking or breaking down over time.1 This is crucial for tandoor oven clays, as they experience extreme temperature fluctuations each time the oven is fired up or cooled down after cooking.

Some key factors that influence a clay’s thermal shock resistance include:2

- Composition – Silica and alumina content affect strength and thermal expansion.

- Porosity – More porous clays withstand shock better by absorbing stresses.

- Microcracks – Small internal cracks dissipate stress through the material.

- Grain shape – Elongated grains transfer stress more easily.

The clay must maintain integrity over hundreds or thousands of high heat cooking cycles. Thermal shock resistance ensures the tandoor remains usable for years without cracking or breaking down.

Ease of Molding

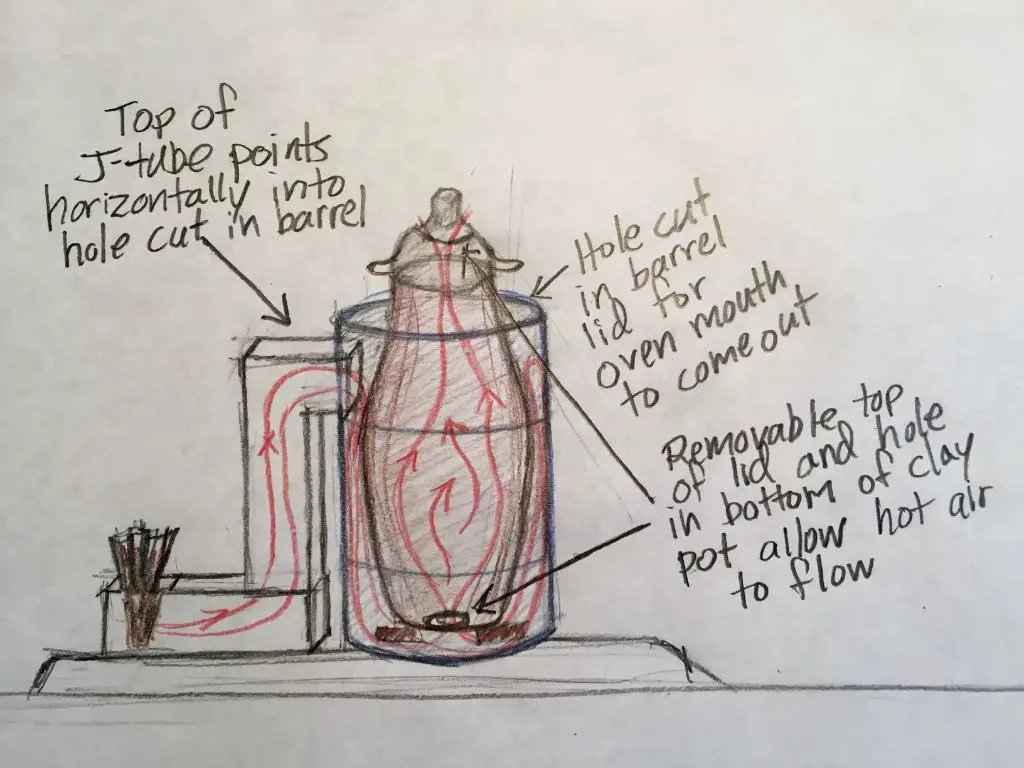

The clay used for tandoor oven construction needs to be malleable enough to mold into the proper shape, but also maintain that shape once constructed. As outlined in this instructional for building a tandoor oven from scratch (https://www.instructables.com/Building-a-Tandoor-From-Scratch/), the clay must be wet enough to mold by hand or on a potter’s wheel, but should also be sturdy enough to keep its form during the drying and firing process. Some clays, such as natural earthen clays, may be too brittle or prone to cracking when molded into the tall, rounded shape of a tandoor.

Polymer-based modeling clays (https://www.amazon.com/molding-clay-oven-bake/s?k=molding+clay+oven+bake) can be easier to mold into complex shapes and retain their form once baked. The flexibility and moldability of polymer clays makes construction simpler compared to natural clays that require more time and skill to sculpt smoothly. However, polymer clays may not achieve the same level of heat resistance as natural earth clays designed specifically for high-temperature firing.

Cost

The cost of clay can vary significantly depending on the type and quality. According to Statista, the average price of common clay in 2023 was around $17 per ton. Specialty clays like porcelain and stoneware tend to cost more, ranging from $20-50 per ton. Premium ceramic clays can cost over $100 per ton. The purity and mineral content affects the price – highly refined kaolin or ball clays are more expensive than locally sourced common clays.

Higher priced premium clays result in high quality pieces that require less finishing work. They have excellent throwing properties, produce vibrant glazes, and can withstand very high firing temperatures. Many ceramic artists feel the premium clays are worth the extra cost. However, inexpensive clays can also produce quality work, especially for beginners. Factors like local availability and intended use should be considered when selecting a clay body for cost reasons.

Environmental Factors

When choosing a clay for a tandoor oven, it’s important to consider environmental factors like using locally available materials and sustainability concerns.

Opting for a locally sourced clay reduces transportation emissions and supports local economies (https://www.nucleodoconhecimento.com.br/environment/clay-extraction). However, clay extraction can negatively impact the environment through deforestation, soil erosion, and habitat destruction. Sustainable clays like red art clay fired at lower temperatures may have less environmental impact (https://typeset.io/questions/what-are-the-environmental-impacts-of-clay-material-45qmfwc16z).

Consider if the clay can be recycled or reused after its lifespan in the tandoor oven. Some clays high in grog or chamotte can be recycled into new clay after firing. Choosing sustainable clays and locally-sourced materials can reduce environmental impact.

Recommendation

Based on the key factors of heat resistance, thermal conductivity, porousness, density, shock resistance, moldability, cost, and environmental factors, the best clay for constructing a tandoor oven is a blend of fireclay and quartzite (less than 30% quartzite) (source). Fireclay provides excellent heat resistance up to 2300°F and good thermal shock resistance. The addition of quartzite improves thermal conductivity. Using a blend creates a sturdy porous ceramic able to withstand the high temperatures and thermal shock that occur inside a tandoor oven.

When constructing the tandoor, reinforce the lower half of the cylinder with quartzite grog for enhanced durability. Allow the clay to air dry slowly to prevent cracking. Fire the tandoor gradually over 2-3 days up to around 2000°F to fully vitrify the clay. Apply multiple coats of food-grade sodium silicate as a sealant to help the pores vitrify and prevent absorption of food odors/particles. Avoid sudden heating or cooling during use to prevent thermal shock damage.