Is Silver Clay Real Silver?

What is silver clay?

Silver clay, also known as precious metal clay (PMC), is a pliable material made of fine silver particles mixed with an organic binder and water (Metalclay, n.d.). The silver content typically ranges from 60-80% pure silver. There are several major brands of silver clay including Art Clay, PMC, and Cool Tools.

Silver clay is produced by mixing microscopic particles of 999 pure silver with water and an organic binder material such as cellulose gum. This mixture results in a flexible, clay-like material that can be hand molded into different shapes and designs. The clay retains moisture well allowing artisans ample time for detailed shaping and texturing before drying.

In its dried but unfired state, silver clay is very soft and fragile. However, once fired in a kiln at high temperatures, the binder burns away leaving a pure silver piece that is solid and durable. The resulting silver content is 99-99.9% pure.

Composition of silver clay

Silver clay consists of a few main ingredients mixed together into a malleable putty-like material. The key ingredients in most silver clay include fine silver powder, an organic binder material, and water.

The fine silver content, usually around 99.9% pure silver powder, comprises 50-80% of the total silver clay volume. This high purity silver powder is what allows the final fired piece to be 99-99.9% pure solid silver. The remaining portion is the binder material and water.

Common binder materials used are plant-based organic materials like cellulose gum or cornstarch. These act like a glue to hold the silver particles together in a pliable state. Water makes up the remainder to get the clay to the proper consistency for sculpting and shaping.

So in summary, while not 100% pure silver in its unfired state, silver clay consists mostly of ultra pure silver particles suspended in minimal binder and water. The final fired silver piece will be nearly pure solid silver.

How pure is the silver in silver clay?

Silver clay contains fine silver particles suspended in an organic binder and water. The purity of the silver particles in silver clay ranges from 95-99% pure silver, depending on the type of clay.

Most major silver clay brands like Art Clay Silver contain 95-96% pure silver particles before firing. This is comparable to the purity of sterling silver, which is 92.5% pure silver.

According to Art Clay Silver product details, their silver clay contains 95% pure silver particles. Pieces made with Art Clay Silver can be marked as sterling silver after firing.

In summary, silver clay contains high purity silver particles on par with sterling silver purity. The silver purity ranges from 95-99% depending on the clay type, with 95% purity being most common.

Silver clay firing process

Once a piece has been shaped from silver clay, it must be fired in a kiln to burn off any binders and fuse the fine silver particles together into solid pure silver. Firing can be done with a kiln, torch, or oven according to the manufacturer’s instructions.

Silver clay is normally fired at around 650-800°C depending on the type and brand of clay used. Before firing, the clay contains fine silver particles held together by an organic binder and is quite soft and moldable. After firing, the binders burn away leaving behind solid 99.9% pure silver. The color also changes from gray to bright silver. Proper firing ensures that all binders are burned off and the silver particles are fused together into a strong, pure silver piece.

Resulting pure silver piece

The finished silver piece resulting from firing silver clay has a beautiful, lustrous appearance similar to cast fine silver jewelry. This is because the binders and other non-silver ingredients in the clay burn away during firing, leaving behind 99.9% pure silver.

The purity of the finished silver piece is thus equivalent to .999 fine silver. It has the same soft, malleable properties as cast silver pieces. The surface will have a slightly porous, matte texture from the clay unless additional finishing techniques like hammering or tumbling are used to compress and polish the surface.

Overall, the resulting silver has an attractive white metallic sheen. It can be worked, soldered, patinated, and polished like any other fine silver to achieve different finishes. The fired clay transforms into a durable, solid silver that is indistinguishable from silver produced through other jewelry methods.

Sources:

https://silver-clay.com/pages/finishing-precious-metal

Advantages of silver clay

Silver clay offers many benefits over traditional silver smithing techniques. The clay is very easy to work with and mold into detailed shapes. According to Jewellers Academy, “It’s easy to do from home – there is not much equipment that you need to get started” (source). The clay is soft and pliable, allowing jewelry makers to create delicate and intricate designs not possible with other methods.

Jewellery Schools Scotland notes that silver clay is “soft and malleable, allowing for precise impressions of textures such as fabric, leaves, or intricate patterns. This makes it ideal for making detailed, organic looking jewellery pieces” (source). After firing, the finished silver piece retains all of the fine details originally sculpted.

Overall, silver clay greatly simplifies the silversmithing process. Jewelry makers can sculpt directly in silver rather than fabricating pieces from sheet and wire. The clay enables intricate designs and eliminates many steps compared to traditional fabrication methods.

Disadvantages of silver clay

While silver clay offers many unique advantages, it also has some limitations and extra steps compared to working with traditional sterling silver metal. According to Pros and Cons of Precious Metal Clay, silver clay is quite fragile before firing. Pieces must be handled carefully and allowed to dry fully to avoid cracking or breaking. The clay also shrinks 8-10% during firing, so pieces must be sculpted slightly larger to account for shrinkage.

Additionally, working with silver clay requires multiple steps including sculpting, drying, firing, and polishing. With traditional sterling silver metal, pieces can simply be fabricated, soldered, and polished. The firing process for silver clay also requires either a kiln or handheld torch. This extra equipment can add cost and time compared to working solely with metal sheet and wire.

While silver clay offers the ability to hand sculpt detailed forms not possible with metal fabrication, the fragility, shrinkage, and multiple steps can be limiting compared to direct metal working. However, many jewelry artists find the unique advantages of silver clay worth the extra care and process requirements.

Example creations

Silver clay allows jewelry artists and crafters to create intricate, one-of-a-kind designs that would be difficult or impossible to make using traditional silver fabrication techniques. The malleable clay can be shaped into thin sheets, extruded into wires, and molded into complex 3D forms before being fired into 99.9% pure silver metal.

Some unique creations made with silver clay include:

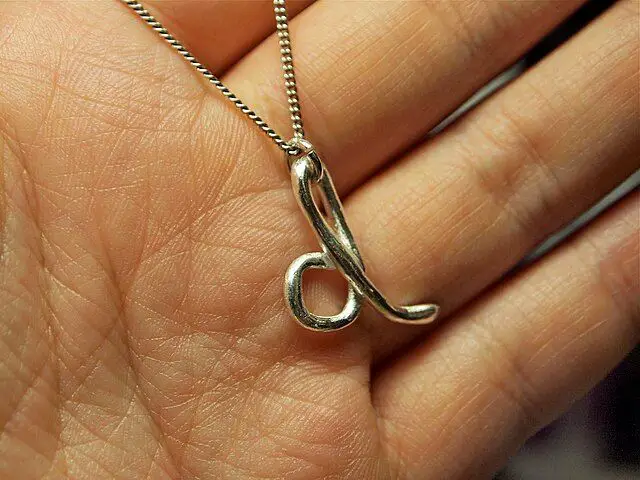

- Intricate pendants, beads, and charms with fine details like filigree and textures.

- Miniature sculptural artworks like small figurines, vessels, and decorative objects.

- Custom elements like clasps, findings, and embellishments for jewelry.

- Wedding rings, earrings, bracelets, and other personalized jewelry pieces.

- Artisan buttons, brooches, cufflinks, and other wearable silver objects.

The flexibility of the clay medium allows artists to handcraft one-of-a-kind designs not possible with cast or fabricated silver. Pieces can include delicate openwork, carved textures, and molded shapes tailored to the wearer. When fired, the resulting pure silver has a beautiful finish and luster.

Is silver clay real silver?

Yes, silver clay is made of pure silver and the finished pieces are real solid silver. Silver clay, also known as precious metal clay (PMC), is made from microscopic particles of 999 silver that are mixed with an organic binder and water to create a pliable clay-like material [1]. Though in its initial state the silver content is only 60-80%, after firing the finished piece is 99-100% pure silver.

During the firing process, which involves heating the piece to high temperatures, the binder burns away completely leaving only pure silver metal behind. This results in a solid silver piece that can be hallmarked and stamped as sterling 925 or fine 999 silver [2]. The piece will not tarnish or lose its shape over time.

The advantages of silver clay include its versatility for creating detailed silver jewelry or art pieces without expensive equipment. It’s an accessible medium for hobbyists and jewelers. However, the clay requires careful drying and firing technique to avoid cracking or warping of the piece.

The takeaway

In summary, silver clay is an amazing material that allows anyone to create beautiful pure silver jewelry and art objects. The clay contains fine silver particles mixed with an organic binder and water, which can be shaped into any form when moist. Once dried, the pieces are fired which burns away the binder leaving behind 99-99.9% pure silver. The resulting silver is just as pure, valuable, and precious as traditionally cast silver.

Silver clay is an excellent choice for jewelry makers, artists, and crafters of all skill levels. Even complete beginners can achieve professional looking results without any metal working experience. It offers a very accessible way to work with precious metals. The clay can be shaped by hand or with simple everyday tools and then fired in a kiln, with a handheld torch, or even with a gas stove burner. Cleaning and polishing after firing completes the pure silver piece.

While traditional metal working requires many tools, machinery, and skills that take years to master, silver clay simplifies the metal smithing process. It allows creators to skip the casting, soldering, sawing, and filing steps. The instant gratification of making a wearable silver piece in hours rather than weeks makes silver clay extremely rewarding for beginners. For professional jewelers, silver clay offers new creative possibilities as well.

Overall, silver clay delivers on being real, pure silver in an easy moldable form. It opens up metal clay crafting to anyone passionate about making their own jewelry, mini sculptures, ornaments, and more.