Is A Clay Pot The Same As Terracotta?

Clay is a natural material made up of fine-grained minerals such as kaolinite that can be molded when wet and hardens when fired or dried. Terracotta refers specifically to a type of fired clay that has an earthy orange-red color. It is an ancient material that has been used for pottery, sculpture, and construction since antiquity.

The goal of this article is to provide a comprehensive overview comparing clay pots and terracotta. We will examine the composition, manufacturing process, properties, uses, advantages, and disadvantages of each to understand if there is a difference between these two terms or if they can be used interchangeably.

Composition

Terracotta clay is made from a specific type of clay called earthenware clay. Earthenware clay contains iron and other mineral impurities which give terracotta its distinctive orange-red color after firing. The clay used for terracotta is generally a secondary clay, meaning it was transported from its original source by water and deposited somewhere else over time. This gives the clay particles more time to weather and break down into a smooth, workable consistency.

The most common clays used to create terracotta are red and brown firing clays. These include clays such as red art clay, brown stoneware clay, and iron-rich clays. The iron oxide content in these clays provides the rich orange-red tones. Terracotta can also be made from white firing sculptural clays by adding iron oxide mineral pigments. The purity and mineral content of the clay determines the color and properties of the finished terracotta product.[1]

In summary, terracotta is made from an iron-rich, earthenware clay that fires to a distinctive orange-red color. The most commonly used clays are red and brown firing clays that naturally contain iron oxide mineral pigments.

[1] https://www.soulceramics.com/pages/what-is-terracotta-clay-made-of

Manufacturing Process

Terracotta begins with natural clay that is mined from the earth. The raw clay is then purified to remove rocks, shells, roots and other impurities. Next, the clay goes through a wedging process where it is kneaded to remove air pockets and create an even consistency. The wedged clay is then shaped into the desired form using hand modeling, throwing on a potter’s wheel, or pouring into molds.

Once the terracotta pieces are shaped, they are set aside to air dry slowly for several days. Then the pieces go through a bisque firing in a kiln at a high temperature which hardens the clay into a permanent form. After firing, the bisque ware terracotta can be decorated with colored glazes and fired again at an even higher temperature to create a glossy finish. Unglazed terracotta maintains an earthy, porous look.

The entire process from mining the natural clay to the final firing takes skill, labor and time. But the resulting terracotta pottery is durable, practical and retains the natural beauty of clay.

Properties

Terracotta is known for its distinctive reddish-orange color. This color develops during the firing process as iron oxide in the clay mixture chemically changes under high temperatures. The final color can range from pink, orange, red, brown, and even gray depending on the clay composition and firing temperature. Terracotta fired at higher temperatures generally results in brighter red and orange hues.

Terracotta is porous and permeable to water and air. This porosity comes from air pockets that form within the clay during manufacturing. However, a glazing can be applied to the surface of terracotta to make it non-porous. Unglazed terracotta is more prone to stain and decay when exposed to weather.

Terracotta has moderate strength and durability. It is much stronger than unfired clay but not as strong as stone. The compressive strength and hardness depends on the firing temperature and composition. Terracotta fired at higher temperatures is generally denser and stronger.

Terracotta has low thermal conductivity and a high heat capacity. This gives it good insulation properties against heat transfer. It takes a long time to heat up or cool down which helps regulate indoor temperatures.

While not very flexible, terracotta has good shock resistance compared to more brittle materials like stone or ceramic. Smaller units are easy to handle without damage.

Terracotta has excellent resistance against chemicals, acids, water, and weathering when properly fired and glazed. With proper maintenance and protection, it can last for centuries.

Uses

Terracotta has been used for a wide variety of purposes across many cultures and time periods. Some of the most common uses of terracotta include:

Sculpture – Terracotta is one of the most common materials used in sculpture. Its clay can be easily molded into complex shapes and designs. Once fired, terracotta sculptures retain their form while still being relatively lightweight.

Pottery – From ancient times until today, one of the primary uses of terracotta has been to make pots, vases, bowls, plates and other vessels. Its natural reddish-orange color after firing makes it attractive as well as functional.

Construction – In many parts of the world, terracotta has long been used in construction. Terracotta bricks and tiles have been widely used in architecture. In modern times, architectural terracotta continues to be used for both practical and decorative purposes.

Tilework – Glazed and unglazed terracotta tiles have been used to decorate floors, walls, countertops and other surfaces, both indoors and out. Terracotta tiles are appreciated for their natural rustic beauty.

Cookware – Due to its durability and ability to retain heat, terracotta has traditionally been used to make items like tagines and bean pots for cooking.

Gardenware – Pots, urns and other terracotta containers are very popular for gardens and landscaping because they allow ventilation and drainage.

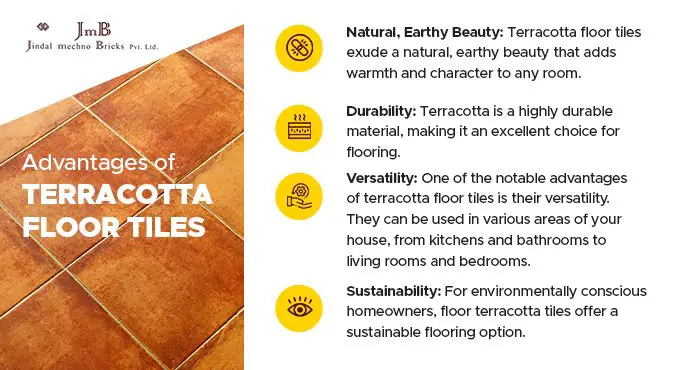

Advantages of Terracotta

There are many benefits that make terracotta a popular material choice for pottery and other objects. Some key advantages include:

Durability – Terracotta is fired at high temperatures which makes it very durable and strong. It is resistant to weathering and can last for decades or even centuries (Soendgen).

Porosity – The porous nature of terracotta allows air and moisture to pass through. This creates a healthier environment for plants in terracotta pots as it prevents overwatering (Terracotta Algarve).

Temperature Regulation – Terracotta has thermal mass properties allowing it to absorb and radiate heat slowly. This helps regulate temperatures and maintain cooler temperatures in hot conditions (EcoStore).

Aesthetics – Terracotta has an earthy, rustic aesthetic appreciated for its natural beauty. The colors and textures provide visual interest. When unglazed, it can develop a unique patina over time.

Availability – Clay is an abundant natural resource making terracotta relatively inexpensive and widely available.

Disadvantages of Terracotta

While terracotta offers some benefits, it also has some downsides to consider. One of the main disadvantages of terracotta tiles is their weight. Because they are made from dense clay, terracotta tiles tend to be much heavier than other tile materials like ceramic or porcelain (source). This added weight can make them more difficult to transport and install. It also means that extra structural support may be needed in flooring or roofing applications to handle the load.

Another drawback is that unglazed terracotta is porous and permeable to water. According to DesignSwan, the clay material can absorb a lot of moisture, which makes the tiles prone to staining and damage over time if not properly sealed (source). Unglazed tiles are also more difficult to clean. On roofing, moisture absorption can lead to leaks or promote algae and moss growth.

In addition, terracotta is relatively brittle and fragile compared to other materials. The tiles can crack or break under impact or excessive stress. StockCabinetExpress notes that dropping a heavy object on terracotta floor tiles can easily cause chipping or cracks (source). The fired clay also has a tendency to warp or shrink over time. This fragility makes terracotta less ideal for high traffic areas.

Finally, terracotta’s reddish-orange color is difficult to modify or glaze in a wide range of hues. Design options are more limited compared to ceramic or porcelain tiles that can be decorated with countless colors, patterns, and finishes. While some view the natural terra cotta tones as warm and attractive, it also limits coordination with some color schemes.

Comparisons

Terracotta differs from other types of clay in several key ways:

Compared to earthenware, terracotta is less porous and more durable. Earthenware is soft, porous clay that can easily absorb liquids. In contrast, terracotta has been fired at a high temperature to produce a denser, watertight material.

Unlike stoneware, terracotta is not vitrified. Stoneware undergoes a firing process that causes the clay particles to fuse together into a nonporous, rock-like material. Terracotta retains its porous, earthen quality despite being fired at high temperatures.

Terracotta differs from porcelain due to its coarse texture and reddish-orange color. Porcelain clay produces a smooth, white ceramic when fired. Terracotta has a gritty texture that is left unglazed to showcase the natural terra cotta (earth) color.

While versatile clays like polymer and epoxy clay can mimic the look of terracotta, they lack the durability and thermal properties of real fired clay. These artificial clays also do not provide the same porous qualities for functions like water filtration.

Notable Examples

Some of the most famous examples of terracotta art and sculpture include:

The Terracotta Army in Xi’an, China is one of the most significant archaeological excavations of the 20th century. This life-size army of over 8,000 terracotta soldiers was created around 210 BCE for the burial of Qin Shi Huang, the first emperor of China. The figures vary in height, uniform, and hairstyle according to rank [1].

The ancient Greeks produced large numbers of small terracotta figurines, such as the Tanagra figurines and South Italian black-figure pottery. These were often religious in nature, such as figures of deities [2].

The Burney Relief is an ancient Mesopotamian terracotta plaque from around 1800 BCE that is considered one of the greatest archaeological finds of the 19th century [2].

The Haniwa funerary objects of Japan were terracotta clay figures that were buried with the dead as grave goods. The Period of Haniwa Production lasted from the third to the sixth centuries CE [1].

Conclusion

As we have seen, clay pots and terracotta pots are very similar in many ways. Both are made from natural clay that has been shaped into pottery and fired at high temperatures in a kiln. The main difference lies in the type of clay used – terracotta specifically refers to items made from reddish-brown earthenware clay. However, many clay pots are also made from this terracotta clay. Ultimately, terracotta can be considered a type or subset of clay pots, differentiated by the distinct terracotta clay used in its manufacture. While the terms are sometimes used interchangeably in everyday language, technically terracotta refers to a clay pot made from a certain type of clay. But in general usage, terracotta pots are simply a variety of the broader category of clay pots. So in summary, the terms refer to quite similar items with just a small distinction in the clay composition. But for most practical purposes, terracotta pots and clay pots can be considered the same thing.