At What Temperature Can You Open A Glass Kiln?

Glass kilns are high-temperature ovens used to melt, fuse, slump, or cast glass.

Opening a glass kiln requires caution, as the internal temperature can easily exceed 1000°F. Prematurely opening the door risks shattering projects or damaging the kiln. However, waiting too long wastes time and energy.

Proper opening temperature depends on the glass thickness and intended effect. But generally, glass kilns should be cooled to 200-300°F before removing contents. This prevents thermal shock while allowing reasonable cooling times under 24 hours.

Knowing the ideal temperature for safely accessing glass pieces ensures efficient, successful firings. This guide covers the consequences of improper opening and techniques to determine when kilns are ready.

Recommended Opening Temperatures

The recommended temperature range to open a glass kiln is typically between 100°F – 150°F (38°C – 66°C), according to sources like warmglass.com. However, the ideal temperature can vary based on factors like the type of kiln, the type of glass used, and the goals of the project.

For example, top-loading kilns tend to retain heat longer than front-loading kilns. So a top loader may need to cool down closer to 100°F before opening, while a front loader could potentially be opened at 140°F safely. The thickness and mass of the glass pieces also impacts the time needed to cool. Thicker, heavier pieces require more cooling time than thinner, smaller pieces before the kiln can be opened.

The intended effect on the glass is also a consideration. If aiming for a full fuse with smooth, rounded edges, the glass must cool slowly to room temperature. But if going for a tack fuse with sharper edges, the kiln door can be opened earlier while still hot to speed up cooling. Consulting the specifications provided by the kiln and glass manufacturers is advised to determine the optimal temperature for the particular project.

Consequences of Opening Too Early

Opening a glass kiln before it has fully cooled can lead to disastrous results for your glass creations. The most significant risk is thermal shock, which can cause cracks, fractures, or even shatter your glass projects into pieces.

Thermal shock occurs when there is a rapid change in temperature in the glass. If you open the kiln prematurely, the glass pieces inside go from being extremely hot to being exposed to much cooler room temperature air. This sudden temperature change causes different parts of the glass to expand and contract at different rates, creating stress forces in the material. If these stresses exceed the strength of the glass, cracks and breakage can result.

The severity of thermal shock depends on the temperature difference, thickness of the glass, and the rate of change. Thick slab glass and intricate sculptural pieces with thin sections are most vulnerable. However, even smaller items like bowls, vases, cups, and plates can experience thermal shock damage when removed from a kiln before adequately cooled.

To avoid destruction of your prized glass artworks, patience is required when opening a kiln after firing. The door should only be opened once the internal temperature has normalized with the ambient room temperature. Moving too quickly risks jeopardizing all your hard work.

Consequences of Opening Too Late

Overheating glass by leaving it in the kiln too long carries risks. As glass heats to higher temperatures, it begins to soften and flow. Prolonged exposure to heat can cause glass projects to become misshapen or warped. The glass structure changes at high temperatures, leading to a difference in the refractive index, which can alter the color or transparency of the glass. Overheating glass also increases the chance of devitrification, which is when the glass becomes crystalline or cloudy

According to The Basics – Kilns | Ceramic Pottery Kiln, Glass … (https://skutt.com/skutt-resources/resources-just-for-you/artist/the-basics/), “If you open it too soon, the glass could be susceptible to thermal shock and break. As you unload the kiln make notes in your firing log regarding how the glass looks.” Therefore, it’s important not to overfire glass by leaving it in too long, as this can lead to unwanted changes in the appearance and structure of glass art projects.

How to Measure Kiln Temperature

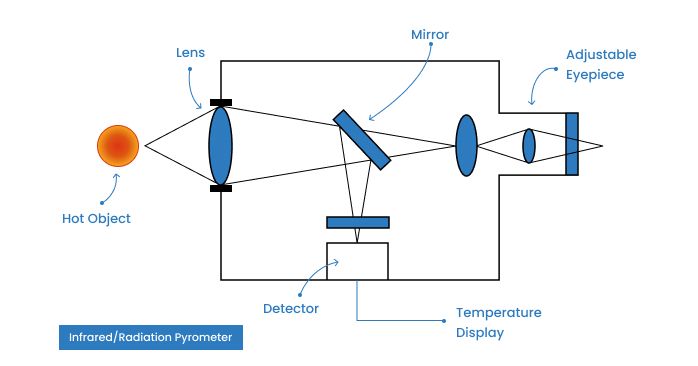

There are a few different methods for manually measuring kiln temperature. One of the most common is using witness cones. Witness cones are small pyramids made of glass that melt at specific temperatures. By placing a series of witness cones inside the kiln and observing which ones bend over, you can get a rough estimate of the kiln’s temperature range. However, witness cones only provide a ballpark figure and don’t give a precise temperature reading.

Another manual method is using kiln washers – these are plaque-like pieces of glass with spots of enamel that melt at certain temperatures. By checking which spots have melted after a firing, you can again estimate the temperature. But this is an imprecise way to measure.

For the most accurate way to know your kiln’s exact temperature, use a pyrometer. This is an electronic device with a thermocouple probe that inserts into the kiln through a peephole. The pyrometer gives a digital readout of the real-time temperature inside the kiln. This takes the guesswork out and allows you to confidently fire your pieces to the proper temperature. Pyrometers designed for glass fusing and slumping are affordable and a great investment for any serious glass artist (Source).

Letting the Kiln Cool

It’s important to let your kiln cool slowly and gradually before opening the door. According to warmglass.com, letting the kiln cool too quickly can lead to thermal shock, causing glass projects to crack or shatter.

The general recommendation is to allow the kiln to cool below 200°F before opening the door, according to kilnfrog.com. At 200°F, the glass will still be warm but cool enough to avoid damaging your projects with rapid temperature changes.

Some tips for safely cooling your kiln include:

- Turn off the kiln and allow it to cool naturally without opening the door.

- Avoid fanning or forced cooling. This can speed up cooling too rapidly.

- Check the internal kiln temperature with a pyrometer before opening.

- Crack the kiln door slightly for the first few minutes to allow heat to escape slowly.

- Wear heat-resistant gloves when handling hot kiln shelves or glass.

Taking the time to let your kiln cool gradually will help ensure your glass creations make it through the firing safely.

When It’s Safe to Open the Door

It can be tempting to crack open the kiln door to check on your glass pieces before the kiln has fully cooled. However, this should be avoided, as exposing glass to rapid temperature changes can lead to fractures or even shattering. Instead, there are a few visual and temperature cues to look for to know when it’s safe.

The most obvious is a collapsed kiln shelf. Kiln shelves are designed to support the weight of glass projects while hot. As the kiln cools, the shelves will sag and eventually collapse fully. This is a clear sign that the kiln has cooled significantly and it’s nearing the point where it can be opened. According to Glass Campus, once the shelves have sagged, the kiln temperature has likely fallen below 1000°F.

The type of glass used will also impact the minimum safe opening temperature. Most art glass has an annealing point around 950-1000°F, while borosilicate glass can be annealed around 800°F. It’s recommended to invest in a pyrometer to accurately read kiln temperatures. Once the temperature falls below the annealing point of the glass by at least 200°F, it is generally safe to open the door briefly.

Removing Glass Projects

After allowing the kiln to cool completely, it is time to carefully remove your glass projects. However, exercise caution when handling newly fired glass, as the materials can still be hot or fragile if removed too soon. According to experts, fused glass requires annealing time to normalize temperature. Removing projects before they cool thoroughly may lead to fractures or breaks. For safety, allow adequate cooling time based on the kiln manufacturer’s instructions.

When ready to extract your artwork, wear protective gloves to guard against burns. Carefully lift each shelf or fiber paper one at a time to access the glass pieces underneath. Use tweezers or firing pins to gently lift each project and place on a heat-safe surface for inspection. Go slowly and steadily to avoid damaging the glass. Be prepared to leave projects in the kiln longer if they still feel hot or appear prone to cracking. With patience, you can successfully unload your fired glass creations.

For tips, check out this video on safely removing glass after firing: https://www.youtube.com/watch?v=MzO5JhpQFaQ

Proper Studio Conditions

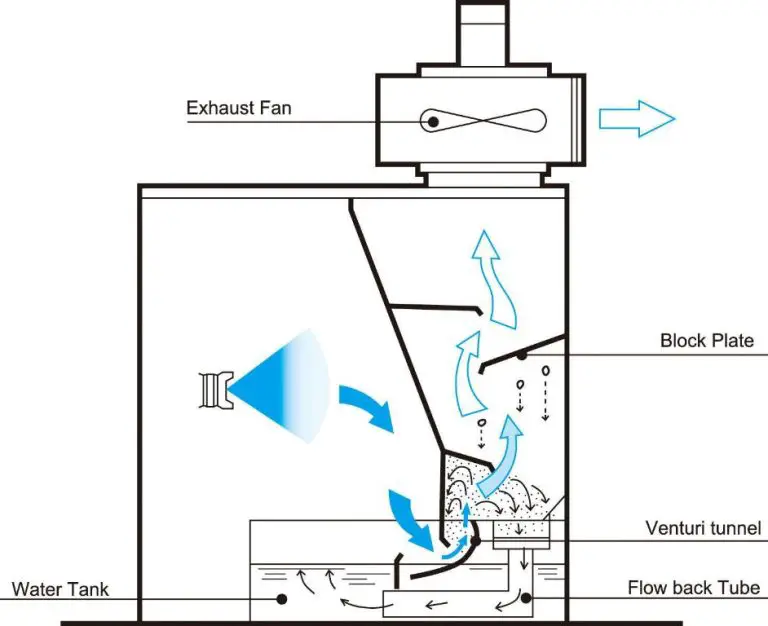

When opening a hot glass kiln, it’s important to have proper ventilation in your studio. Glass kilns can release harmful fumes when opened at high temperatures, so you’ll want to make sure there is adequate airflow to clear out any fumes.

The most critical time for ventilation is right when you first crack the kiln door open. This allows any initial bursts of fumes to dissipate quickly. Opening windows and doors can help encourage cross breezes. Using exhaust fans to actively pull air out of the studio is ideal (Bullseye Glass).

Make sure any fans are pulling air away from you when standing in front of the kiln, so you don’t inhale fumes. Also be cautious about fans blowing fumes into other rooms of your studio or home if they share a ventilation system.

In addition to ventilation, proper safety gear is recommended when opening a hot kiln. Heat-resistant gloves up to 500°F or higher will protect your hands and arms when briefly cracking the door. Safety glasses will shield your eyes in case of glare or steam. An N95 mask can also filter out harmful particulate matter. Remove rings and other jewelry that could conduct heat.

Having a clear, unobstructed path around the kiln is also important for safety when opening and unloading. Make sure to keep the area tidy and free of tripping hazards. Proper studio conditions will help make opening your glass kiln as smooth and safe as possible.

The optimal temperature range to open a glass kiln is between 100-150°F once the kiln has completed the annealing cycle. However, it’s always recommended to wait until the kiln has cooled down to room temperature before opening, as glass can still experience thermal shock at 150°F. Patience is key when opening a kiln, rushing the process risks breaking projects.

Conclusion

When firing glass in a kiln, proper opening temperatures and procedures are critical for success. Allowing the kiln to fully anneal avoids thermal shock, which can lead to cracks and breakage. While technically possible to open the door around 150°F, it’s best to wait until it’s cooled to room temperature. Having patience gives glass time to stabilize and prevents heartbreaking accidents right at the final step.

Rushing to open a hot kiln only risks ruining your work. The extra time is a small price to pay for safely removing your finished pieces. Remember, glass needs time to transition from an elastic state back to rigid. With proper patience and planning, you can feel confident unlocking the kiln knowing your glass creations will be perfectly intact and ready to enjoy.