At What Temperature Does Glass Become Malleable?

Glass is a unique material that can transition between a brittle solid state and a molten, malleable state based on temperature. Knowing the specific temperature range where glass becomes malleable, without fully melting, is critical for glass manufacturing and glass artistry. This temperature range allows glass to be shaped and worked into everything from drinkware to stained glass windows.

The point where glass transitions from a brittle solid into a malleable, doughy material is called the glass transition temperature. This temperature range is key for processes like glassblowing and lampworking. Understanding factors that affect the glass transition temperature also allows glass workers to properly control kilns and account for differences between glass types.

Glass Transition Temperature

The glass transition temperature (Tg) is the temperature at which a material transitions from a hard, glassy state to a soft, rubbery state. For glass specifically, it refers to the temperature at which glass becomes malleable and can be molded into new shapes.

Below the glass transition temperature, the molecules in glass don’t have enough energy to move past each other freely. As glass is heated and approaches its Tg, the molecules gain energy and can move and slide past each other more easily. Above the Tg, glass transitions to a molten, viscous state where it can be shaped and molded relatively easily before cooling back into a rigid solid state.

The glass transition temperature is not a fixed point, but rather a temperature range over which glass gradually transitions from a brittle solid to a malleable material. However, engineers often refer to a single glass transition temperature for simplicity. This is usually defined based on the temperature at which the material’s viscosity is 10^12 Pa*s (https://www.xometry.com/resources/materials/glass-transition-temperature/).

Therefore, the glass transition temperature represents the point at which glass becomes malleable enough to shape and mold into new forms.

Factors Affecting Glass Transition Temperature

The glass transition temperature (Tg) of a glass material is dependent on several key factors related to the composition and structure of the glass. Some of the main factors that affect Tg are:

Glass Composition – The types of compounds used to make the glass have a significant impact on Tg. For example, silicate glasses with high amounts of silica and low alkali content tend to have higher Tg values. Introducing compounds like B2O3 and Al2O3 into the glass composition will lower the Tg.

Cooling Rate – Faster cooling rates during glass formation will result in higher Tg values. This is because faster cooling leaves the glass structure in a higher energy, less relaxed state. Slower cooling allows for more relaxation and molecular rearrangement, lowering the Tg.

Thermal History – Heating a glass above Tg and then re-cooling can lower the transition temperature. This annealing process allows the molecular structure to relax and lowers the energy state of the glass.

Molecular Weight – In polymeric glasses, higher average molecular weights lead to higher Tg values, as the polymer chains are more heavily entangled and less mobile.

Crosslinking – More crosslinked glass networks restrict molecular motion more strongly, increasing Tg. Silicate glasses with higher amounts of network-forming cations like Si4+ tend to have higher Tgs.

Plasticizers – Adding plasticizer compounds lowers the Tg by increasing the free volume and mobility of polymer chain segments.

Typical Glass Transition Temperatures

The glass transition temperature can vary significantly depending on the chemical composition of the glass. Here are some examples of typical transition temperatures for common glass types:

Soda-lime glass, the most common type of glass, has a transition temperature of about 550°C (1022°F). Soda-lime glass contains approximately 70-74% silica (SiO2), 12-16% soda (Na2O), and 8-12% lime (CaO) as its main ingredients. The soda serves as a flux to lower the melting temperature, while the lime helps stabilize the glass.[1]

Borosilicate glass like Pyrex has a higher transition temperature, around 565°C (1050°F), due to having a higher silica content of about 80%. The boron trioxide (B2O3) in borosilicate glass further lowers thermal expansion.[2] This makes borosilicate glass more resistant to thermal shock.

Lead glass contains over 24% lead(II) oxide (PbO), resulting in a density and refractive index substantially higher than normal glass, and a transition temperature around 490–500°C (914–932°F). The lead makes the glass more workable and easier to cut or engrave.[1]

Heating Glass to Make it Malleable

To make glass malleable enough to shape and mold, it must be heated to incredibly high temperatures. This is done in professional glass working studios and factories using specialized furnaces and glory holes.

In glass blowing, the glass is first heated to approximately 2000°F in a large furnace fueled by natural gas or propane. This allows the glass to become soft and malleable so it can be inflated into various shapes on the end of the blowpipe.

According to The Glass Blowing Process – DMG School, “Before starting the glass blowing process, the glass is placed in a furnace that heats it to a temperature of 2000 degrees, making it malleable.” This extremely high temperature causes the glass to transition from a brittle solid state into a molten, pliable state.

Once inflated, the glass is periodically returned to a smaller reheating furnace called a glory hole that maintains a temperature between 2100-2300°F. This keeps the glass soft so it can be continually worked into more detailed shapes.

Proper heating is essential to make glass malleable enough for shaping while avoiding overheating. Glass masters must carefully control temperatures to achieve the precise malleability required for their creations.

Working with Malleable Glass

Once glass is heated to its glass transition temperature, it becomes a viscous liquid that is malleable and can be shaped. There are various techniques used to work with malleable glass:

Glassblowing is the most common technique. A glassblower uses a blowpipe to inflate molten glass into a bubble with breath. The glassblower can then shape the glass by swinging or blowing into the pipe. Complex pieces can be made by repeatedly re-heating and adding more molten glass. Glassblowing requires high temperatures of around 2000°F to keep the glass malleable during shaping (https://dmgschoolproject.org/the-glass-blowing-process/).

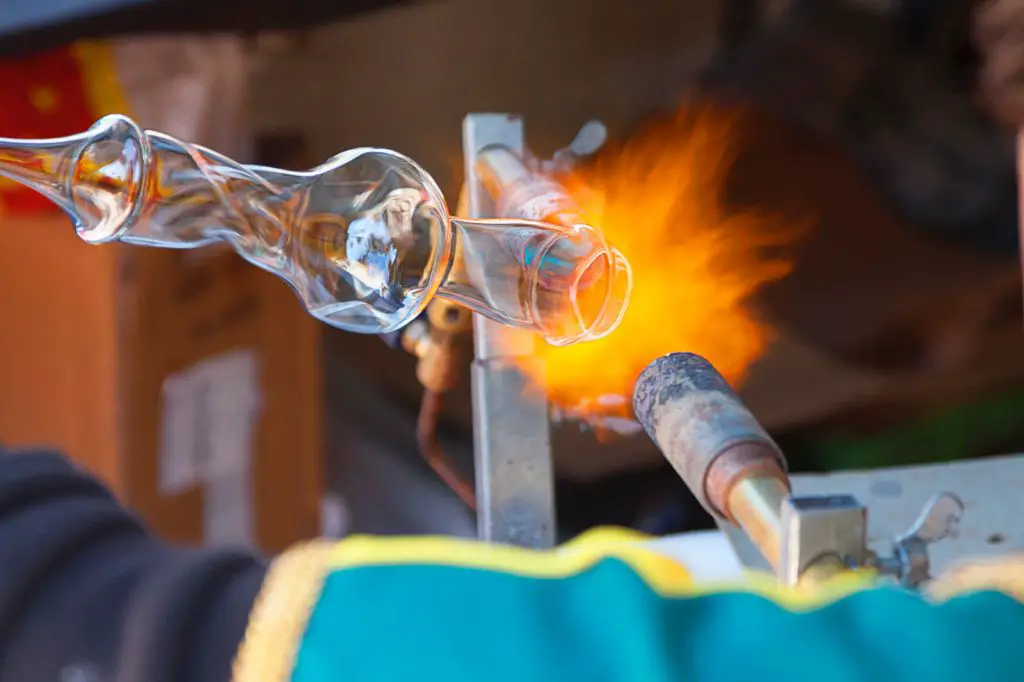

Another approach is lampworking, where a torch is used to melt rods and tubes of glass. The glassworker shapes the glass by manipulating the tubes and rods while heated. This method allows more precise detailing. Popular lampworking projects include glass beads, buttons, figurines, and miniature items.

Casting can be used to mold glass into specific shapes. Molten glass is poured into a mold then allowed to cool slowly to take on the desired form. Slumping involves heating glass sheets until soft, then draping them over a mold to create shapes like bowls or plates. These methods work best for producing multiples of the same item.

Regardless of technique, proper annealing is critical for glass that will be transparent and durable. Annealing entails slowly cooling hot glass objects to relieve internal stresses from fast temperature changes. Without annealing, glass can easily crack or shatter.

Annealing Glass

Newly worked glass is annealed to relieve internal stresses that build up as the glass cools from its working temperature. When glass is heated to become malleable, it expands slightly. As it cools, the outer layers solidify first and contract, while the inner glass is still expanded. This creates stresses that can cause the glass to crack or shatter. [1]

Annealing is a slow, controlled cooling process that allows the stresses to relax gradually. The glass is first heated above its transition temperature, making it malleable. It is then slowly cooled through the annealing range of 500-600°C. As it cools at around 1-3°C per minute, the glass contracts uniformly, avoiding internal strains. [2]

The result is annealed glass that is stable and resistant to cracking from temperature changes or small impacts. Proper annealing is essential for glass products like windows, containers, and artwork to have the desired strength and durability.

Notable Examples

Glass becomes malleable enough to shape and manipulate at temperatures ranging from 1,100 to 1,300 degrees Fahrenheit. Skilled glass artists take advantage of this property to create incredible glass artworks by heating glass until it softens and can be shaped as desired.

For example, many fused glass artists work with powdered or crushed glass that is layered and heated in a kiln until it fuses together into a cohesive whole. The resulting glass plate can then be further shaped and molded while hot to create bowls, plates, jewelry, and more. Fused glass artist Isabelle Moore creates beautiful fused glass plates, birds, and coral sculptures by skillfully manipulating malleable glass.

Another technique is lampworking, where artists heat small rods and tubes of glass over a flame to soften them enough to create intricate beads, figures, and vessels. Skilled lampworkers like Brooklyn-based artist Matthew Szösz can shape molten glass into incredibly life-like forms.

Sandcasting is another process using malleable glass, where hot glass is ladled or poured into a sand mold then cooled. This allows artists like Karen LaMonte to cast stunning glass sculptures of human figures and clothing.

These examples demonstrate the creative potential of glass in its malleable state, allowing artists to shape it into beautiful and imaginative works of art.

Impact on Glass Industry

The ability of glass to become malleable at high temperatures has had a significant impact on the glass industry and glassworking practices. Once heated to the proper temperature, glass becomes soft and malleable enough to shape and work into various forms. This malleable state is essential for techniques like glassblowing, where artisans use tools and molds to manipulate hot, molten glass into intricate shapes and vessels. According to Low Impact, “In its molten state glass is extremely malleable; when cool it’s very hard.”

The malleability of heated glass also enabled advancements in glass manufacturing. With molten glass, it became possible to press and blow glass into standardized molds for mass production. The introduction of machine glass blowing in the early 1900s, where glass is blown into molds by machines, further increased manufacturing efficiency as described by DesignWanted. So the ability to repeatedly soften glass into a malleable state has allowed artisanal glass techniques to flourish while also supporting industrial-scale glass production.

Conclusion

In summary, the temperature at which glass becomes malleable depends on its composition but is typically in the range of 500-900°F (260-482°C). As glass is heated and approaches its glass transition temperature, it gradually softens and becomes workable. Master glassmakers must heat glass into this optimal temperature range to craft intricate glass artworks and products. The ability of glass to transition from a brittle solid to a malleable material has enabled the use of glass for countless applications throughout human history. Understanding the glass transition process allows glassmakers to heat and shape glass precisely for their creative and industrial purposes.