Can I Bisque At Cone 05?

What is Bisque Firing?

Bisque firing, also known as biscuit firing, is the first firing process used in pottery and ceramics. It transforms unfired clay into a stable porous ceramic material through heat, allowing the object to be handled and glazed without risk of damage 1. The purpose of bisque firing is to convert the raw clay into a permanent ceramic state while still allowing it to absorb water in preparation for glazing.

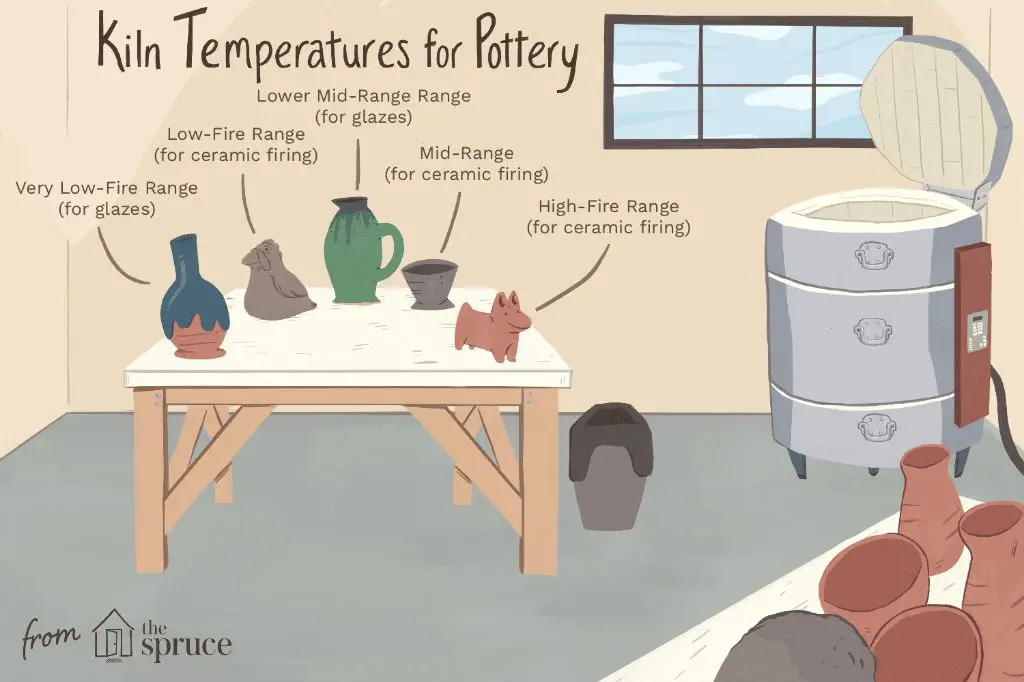

Bisque firing takes place at lower temperatures, usually between cone 04 and cone 06 (1945-2165°F / 1063-1185°C), compared to glaze firing which can range from cone 06 to cone 10 (2165-2345°F / 1185-1285°C). During bisque firing, clay and water are chemically combined and bound together through sintering. This transforms the fragile clay into a strong, porous material ready for decoration and glazing.

Glaze firing occurs after decoration and glazing. It melts the glaze onto the permanent bisque body, creating a glassy coating. The key differences are that bisque firing happens first, at a lower temperature, to permanently fire the clay before glazing. Glaze firing happens afterwards at a higher temperature to bond the glaze to the bisqueware.

Cone 05 Firing Temperature

Cone 05 corresponds to a firing temperature range of approximately 1922-1940°F (1050-1060°C). This is considered a low fire temperature, typically used for firing low fire clay bodies and glazes.

Clay bodies formulated for cone 05 include terra cotta clays, low fire red/brown earthenware clays, and some white earthenware clays. These clay bodies mature and become vitrified at cone 05 temperatures. Typical glazes for cone 05 include low temperature lead-free glazes, terra sigillata, white crackle glaze, and some matte glazes. These glazes melt completely and become glossy at cone 05 temperatures.

According to the Bellevue College firing temperature chart, cone 05 is at the low end of the temperature range considered safe for firing stoneware and porcelain bisque. However, most stoneware and porcelain require higher cone 06-10 temperatures to fully mature.

Considerations for Bisque Firing at Cone 05

There are a few important considerations to keep in mind when bisque firing at cone 05. First is the effect on greenware strength. According to Ceramic Arts Network, bisque firing at lower temperatures like cone 04-06 results in a softer, weaker bisque than firing to cone 08 or higher. The lower bisque temperature leaves more moisture in the clay body, reducing bisque strength.

Shrinkage is another concern with low fire bisque. As explained by Big Ceramic Store, firing to lower bisque temperatures results in less overall shrinkage, which can cause problems if the clay and glaze are not properly matched. It’s important to test both clay body and glazes together when using cone 05 bisque.

The skill level required for successful low fire bisque firing should also be considered. Achieving an evenly heated, consistent cone 05 bisque takes extra diligence. Factors like air circulation, heating elements, and soak times have a greater impact at lower temperatures. While cone 05 bisque is certainly achievable for any skill level with proper kiln knowledge, beginners may find higher bisque temperatures more forgiving.

Benefits of Low Fire Bisque

There are several advantages to bisque firing at lower temperatures like cone 05:

Faster firing times – Because cone 05 corresponds to a lower temperature range (around 1,732°F – 1,848°F), it requires less time for the kiln to reach temperature. This allows the bisque firing cycle to be completed more quickly.

Lower fuel costs – Reaching lower peak temperatures consumes less energy and fuel. Firing to cone 05 uses less electricity or gas compared to higher temperature firings.

Less thermal shock on clay – Fast temperature changes can cause cracks or breakage through thermal shock. The lower heat of cone 05 puts less thermal stress on clay bodies, decreasing the chances of issues from thermal shock.

As noted by Crafty Chica, low fire bisque temperatures provide faster firing with lower costs compared to higher fire options [1]. The lower heat also creates a more porous clay body that is less prone to thermal shock.

Potential Challenges

There are some potential challenges to be aware of when bisque firing at cone 05:

Weaker bisque strength – Bisque fired at lower temperatures like cone 05 does not vitrify and densify as much as higher temperature bisque. This can result in a more porous, weaker bisqued ware. Pieces may be more prone to damage in handling and glaze firing if the bisque is too weak. According to sources like https://digitalfire.com/glossary/bisque, higher temperature bisque firings help strengthen ware.

Increased firing shrinkage – Firing to lower bisque temperatures means the clay body undergoes less shrinkage in the bisque, which gets pushed into the glaze firing. This increased shrinkage during glazing can put more stress on ware and increase risk of cracking or glaze defects.

More limited clay and glaze options – Low fire clays and glazes are specially formulated for cone 05-06 firing. Not all clay bodies and glazes will mature correctly or fit the thermal expansion of the body if bisque fired this low. Bisque temperatures around cone 08-10 provide more versatility with clay and glaze selection.

Tips for Successful Cone 05 Bisque Fires

When firing to lower cone temperatures like 05, there are some extra considerations to ensure your bisque pieces come out properly fired without cracks or other issues.

Use slower bisque firing schedules that ramp up and down in temperature gradually. Extreme temperature changes can cause cracking with lower cone firings. Aim for no more than 200F per hour increase.

Control airflow in your kiln so it is not too rapid. Rapid air movement can lead to uneven heating and cooling which increases cracking at cone 05. Partially close peepholes or prop kiln lid slightly.

Support pieces carefully on stilts and shelves so they do not touch each other during firing. Low fire greenware can be more fragile so preventing any contact will reduce stress and cracks.

Check with your clay and glaze manufacturer’s recommendations for appropriate cone 05 bisque schedules. Their guidance combined with slower ramps, controlled airflow, and supported ware will help ensure successful lower temperature bisque firings.

Testing Your Clay and Glazes

It’s important to test both your clay body and glazes before doing a full bisque firing at cone 05. Small differences in firing temperature can cause glazes to craze, shiver, or not fit the clay body properly. Here are some tips for testing:

Make some small test bars or tiles out of your clay. Bisque fire these at cone 05. For glaze testing, apply glazes to the bisqued test tiles and fire again at cone 05. Check for any glaze defects like crazing or shivering. The glaze should appear smooth and glossy on the tile if it is a good fit for that clay body and temperature.

You can also test glazed pieces that you bisque at cone 05. After the bisque firing, glaze your pieces and fire again at cone 05. Visually inspect the glazed surfaces and check for any problem areas where the glaze didn’t adhere well or is flaking/crazing. Run your finger over the surface and make sure it is smooth.

Testing both the clay body and glazes together will help you determine if they are compatible at cone 05 before you bisque fire a large batch of work. Always test glazes on the specific clay body you will be using, as small changes in clay composition can impact glaze fit even at the same temperature.

Kiln Selection

When bisque firing at cone 05, it’s important to select the proper kiln design and components to achieve the lower temperature ranges. Here are some key considerations:

Kiln design – Look for a kiln designed specifically for low fire applications, often called a “craft kiln.” These kilns allow precise control at lower temperatures. Top loading kilns with side elements can distribute heat more evenly at cone 05 ranges.

Elements – Nickel-chromium elements are typically recommended over Kanthal A1 for firing at cone 05 and below. The nickel-chromium elements are more durable and efficient at reaching the lower temperature range (Source 1).

Thermocouples – Type K thermocouples are preferable over Type S for cone 05 firings. Type K thermocouples provide more accuracy and responsiveness in the lower temperature ranges required for bisque firing at cone 05 (Source 2).

Control panel – Look for a control panel or kiln controller that allows easy programming and control of the bisque firing schedule. Many low fire kilns come with controllers designed specifically for cone 05 firing.

By selecting the proper kiln design and components, you can achieve successful cone 05 bisque firings consistently.

Firing Tips and Techniques

Proper firing techniques are important for achieving successful cone 05 bisque firings. Here are some tips:

Stacking Pieces in the Kiln: Strategically stack pieces in the kiln to promote even heat circulation. Place pieces so they don’t touch each other and leave adequate space between shelves. Avoid stacking pieces directly on top of each other. Stagger pieces in a brick-like pattern.

Using Witness Cones: Place small witness cones throughout the kiln that melt at the target temperature. This allows you to visually verify when pieces have reached the proper firing temperature. Look for the cones to bend over when the target temperature is reached.

Monitoring Kiln Atmosphere: Track oxygen levels in the kiln to prevent reducing conditions. Sudden drops in oxygen can lead to dark, stained bisque. Open peepholes briefly to reintroduce oxygen if needed. You may need to adjust your firing speed or ventilation to maintain proper oxidation.

When Low Fire Bisque is Not Recommended

While bisque firing at cone 05 offers some advantages, it may not be the best choice in certain situations. There are a few cases where bisque firing at a higher temperature is recommended:

For production pottery that requires very strong, durable ware, a higher temperature bisque is often needed. Bisquing at cone 04 or higher creates a harder, denser clay body that can withstand repeated use and washings. Low fire bisque can be too porous and prone to wear for high volume production.[1]

Some clays and glazes are formulated to mature at higher temperatures, so they may not be compatible with low fire bisque. The clay and glaze chemistries need to align to prevent glaze defects. If using clays and glazes designed for mid-range firing, stick to the recommended bisque cone.

Kilns that cannot steadily hold cone 05 temperatures are also an issue. Kilns with elements that cycle on and off frequently may have trouble getting low enough. The kiln should be capable of maintaining an even heat at cone 05 temperatures for proper bisque firing.