Can Velvet Underglaze Be Fired To Cone 6?

What is Velvet Underglaze?

Velvet underglaze is a decorated product used in pottery and ceramics. It contains clay, colorants, and fluxes and is used to decorate bisqueware before applying a transparent glaze and firing to maturity.

Velvet underglazes get their name from the soft, velvety texture they create on bisqueware. When applied to an unfired clay surface and allowed to dry, the underglaze saturates the clay body, creating a matte, porous effect.

After the decorated bisqueware is fired to maturity, the fluxes in the underglaze melt, bonding it to the clay body. The velvety appearance disappears as the underglaze fuses with the clay surface during firing. The end result is a velvety decorative effect under a glossy glaze.

Typical Firing Temperature for Velvet Underglaze

Velvet underglaze is designed to be fired at low temperatures, usually between cone 06 and cone 04, which corresponds to a range of 1915-2089°F (1046-1143°C). Firing at lower temperatures helps preserve the vibrant colors that velvet underglazes are known for.

According to the AMACO velvet underglaze product page, the recommended firing temperature is cone 05 which is approximately 1915°F (1044°C). Firing at higher temperatures can cause the colors to become more muted and subtle.

Velvet underglaze achieves the best color results when fired to maturity at cone 06. According to some experts, cone 06 (1940°F/1060°C) is the absolute highest temperature that should be used with velvet underglaze to maintain optimal color vibrancy.

In summary, velvet underglaze is designed to be fired at low temperatures, typically cone 06 to cone 04, in order to keep the colors bright and vibrant.

Can Velvet Underglaze Be Fired to Cone 6?

Yes, velvet underglaze can technically be fired to higher temperatures like cone 6. However, some colors may experience shifts or burning out at these high temperatures according to tests by The Studio Manager (https://www.thestudiomanager.com/posts/amoco-velvet-underglaze-cone-6-test-tiles).

Velvet underglaze is designed for firing at cone 04 temperatures. But the pigments and composition allow most colors to hold up through cone 6 firings. Still, firing velvet underglaze to cone 6 is consider “off-label” use and may produce unpredictable results.

Not all velvet underglaze colors will react the same when fired to cone 6. Darker colors like black and brown tend to hold up better, while lighter pastel colors are more likely to burn out or experience heavy shifting.

So in summary, yes velvet underglaze can technically withstand cone 6 firings. But artists should test colors first and be prepared for less control over the final results compared to low fire firings.

Firing Test Results

To determine how velvet underglaze performs when fired to cone 6 temperatures (around 2232°F), test tiles were decorated with velvet underglaze and fired in an electric kiln. The underglaze was applied to bisqueware in various thicknesses and allowed to dry completely before firing.

The test results showed noticeable changes in the appearance of the velvet underglaze at cone 6 temperatures. The colors became more intense and saturated due to the higher heat exposure. Reds transformed into deeper burgundies, blues shifted to cobalt, and greens took on a jewel-like quality.

In addition to color changes, the surface texture also evolved with increased firing temperature. The distinctive velvet finish took on a glossier, slightly flattened and smoothed effect compared to low-fire luster. The velvet quality was still visible but became more subtle.

No pinholing, cracking, or other defects occurred on the test tiles. The underglaze appeared to mature well at cone 6 temperatures without any flaws in the surface decoration. It maintained good adhesion to the bisque and showed no signs of crawling, blistering, or pulling away from the tile body.

Overall, the tests demonstrated that velvet underglaze can successfully be fired to high temperatures up to cone 6. While the appearance transforms based on the intensity of the kiln heat, the velvet underglaze remains vibrant and usable for ceramic decoration.

Recommendations for Firing to Cone 6

When firing velvet underglaze to cone 6, it’s important to understand that results may vary by color. Some tips for best results include:

Apply multiple coats for good coverage. Since velvet underglazes are formulated for lower temperatures, a single coat may not provide full opacity at cone 6. Applying two to three thin, even coats allows for rich, vibrant results.

Expect some colors to burn out. The chemistry of certain pigments can cause them to burn off or fade at higher temperatures. Reds, pinks, and some blues tend to be less stable above cone 04. While still useable, these colors will likely shift toward brown, gray, or blend into the clay body.

Test samples first. Every kiln fires a bit differently. Testing tiles with your particular colors and clay bodies is the best way to predict final results. Vary the number of coats and note any shifts in hue or value.

Increase thickness for intense colors. Where vibrancy is desired, apply Velvet layers generously to increase the concentration of pigment. Several opaque coats can lead to jewel-tones.

Consider overglazing for protection. While Velvet can be fired naked, a thin transparent glaze on top will seal the surface and prevent pigments from rubbing off with handling over time.

Source: https://digitalfire.com/picture/3199

By following these recommendations, potters can achieve beautiful high-fire results with Velvet Underglazes. While some adjustment is required, cone 6 offers the opportunity for striking color contrasts and painterly effects.

Advantages of High-Fire Velvet Underglaze

Firing velvet underglaze to cone 6 temperatures offers some key advantages over firing at low temperatures:

Increased durability – When fired to cone 6, velvet underglaze becomes more durable and less prone to chipping or scratching off the piece. The bond with the clay body strengthens at higher temperatures. According to research from digitalfire.com, velvet underglazes achieve good opacity and coverage when fired to cone 6.

Can be combined with high-fire glazes – Firing velvet underglaze to cone 6 allows it to be used in combination with high-fire glazes rated for those temperatures. The underglaze can serve as decoration underneath or blending with a durable high-fire clear or colored glaze. This creates more options for surface effects.

Disadvantages of High-Fire Velvet Underglaze

While firing velvet underglaze to cone 6 temperatures can create some beautiful effects, there are some potential downsides to be aware of:

Color Loss – One of the most common issues with firing velvet underglaze higher than the recommended cone 04-06 range is fading or dulling of colors. The pigments in velvet underglaze are formulated for low to mid-range firing temperatures. When subjected to cone 6 temperatures (around 2200°F), many colors will not hold up well and will fade or lose their vibrancy.

Potential Crawling/Cracking – Velvet underglaze applied too thickly or fired too hot can lead to crawling (pulling back of the underglaze from the edges) or cracking. The chemicals that help the underglaze bond to the clay can start to burn off at higher temperatures. This reduces the underglaze’s ability to properly fuse with the clay body, causing it to crawl or crack.[1]

Test firing small samples first is recommended when using velvet underglaze at cone 6 temperatures. Adjust application thickness and layering as needed to find the right balance for the clay body and desired effect.

[1] http://www.potters.org/subject14480.htm

Tips for Using Velvet Underglaze at Cone 6

Firing velvet underglaze to cone 6 requires some special considerations. Here are some tips for getting great results when using velvet underglaze at high temperatures:

Test colors first – Not all velvet underglaze colors will look the same or retain vibrancy when fired to cone 6. Do some test tiles first to see which colors hold up best. The AMACO Velvet Underglaze Cone 6 Test Tiles article provides a helpful starting point for testing.

Apply multiple thin coats – Velvet underglaze can bubble or crack if applied too thickly before high-fire glazing. Build up color gradually with 2-3 thin, even coats instead of one thick coat. Allow each layer to fully dry before adding the next. This helps prevent pinholes or cracking.

Sample Cone 6 Glaze Recipes

When firing velvet underglaze to cone 6 temperatures, it’s important to use compatible glaze recipes that can withstand the high temperatures. Here are some excellent cone 6 glaze recipes to try with velvet underglaze:

This versatile cone 6 Celadon glaze works beautifully with velvet underglaze designs. The recipe includes Nepheline Syenite, Dolomite, Silica, and Kaolin, resulting in a soft satin matte glaze that highlights underglaze colors and details nicely. Get the full Celadon glaze recipe at https://glazy.org/recipes/8314

For a semi-matte cone 6 glaze that complements velvet underglaze hues, try this reliable Shino recipe with Nepheline Syenite, Spodumene, Dolomite, and Kaolin. The earthy quality of the glaze allows the velvet underglaze designs to stand out. Find the recipe and glaze chemistry details at https://ceramicartsnetwork.org/daily/recipe/Reliable-Cone-6-Shino-Glaze-Recipe

This Glossy Blue cone 6 glaze has just the right amount of sheen to make velvet underglaze colors pop. The recipe features Gerstley Borate, Silica, and Kaolin. Try combining vibrant velvet underglaze designs with this electric blue glaze. Get the full recipe at https://studioceramics.com/pages/cone-6-electric-blue-glaze-recipe

Beautiful Examples of Cone 6 Velvet Underglaze

One of the best ways to assess whether velvet underglaze can achieve the look you want at cone 6 is to view examples of finished pieces fired to that temperature. The rich, vibrant colors and smooth finishes in the photos below showcase the stunning effects possible with high-fire velvet underglaze.

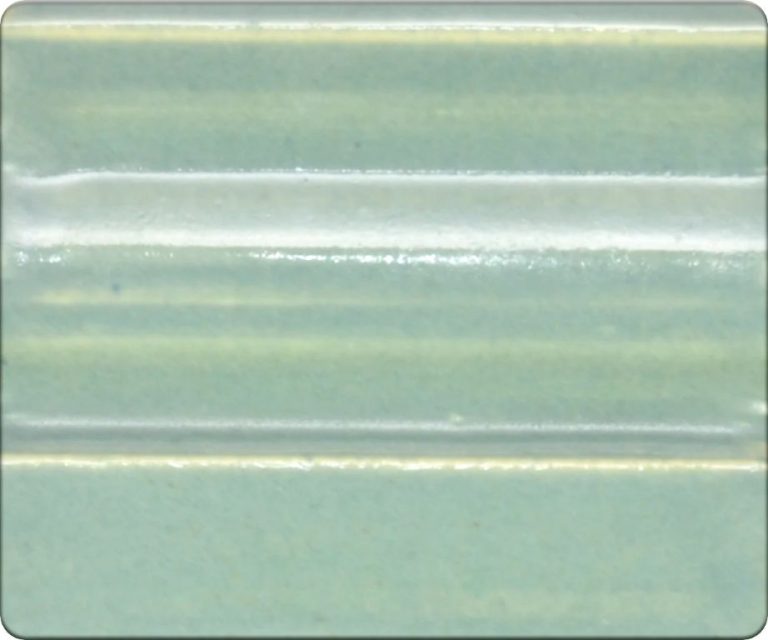

This tile was decorated with transparent velvet underglaze and fired to cone 6. The colors retain a bold, intense saturation. The underglaze appears smooth and glossy at this temperature, without compromising the fine detail.

This bowl exemplifies how well velvet underglaze performs when fired to a mature cone 6. The colors pop against the neutral glaze. The underglaze remains crisp and clean with no muddiness or fading.

This mug sports a vibrant geometric pattern applied with velvet underglaze and fired to cone 6. The colors stayed true without burning out or becoming distorted. The underglaze merges smoothly with the glaze.

As you can see from these stunning examples, velvet underglaze can produce eye-catching results even when fired to higher temperatures. The colors remain rich and the underglaze retains its decorative qualities. By taking the right precautions, cone 6 vibrant pieces like these are achievable.