Can You Use Oven Bake Clay To Make A Pipe?

Have you ever wondered if you can make a pipe out of oven-bake clay? Oven-bake clay, also known as air-dry or cold porcelain clay, is a moldable crafting material that hardens when exposed to air. With the right techniques and care, this versatile clay can be shaped into a fully functional smoking pipe!

In this guide, we’ll walk through the process of using oven-bake clay to handcraft your own customized pipe, from choosing the right clay and molding the shape, to baking, finishing, and testing it out. Read on to learn the ins and outs of making a durable, creative pipe with this DIY-friendly sculpting medium.

Safety Considerations

While polymer clay is considered non-toxic, there are some potential health risks to consider when making a pipe out of oven-bake clay.

First and foremost, smoking from any kind of clay pipe carries risks. Smoking can damage lungs and lead to cancer, heart disease, and other serious conditions. Any pipe intended for smoking should be used with caution.

Specific to polymer clay, there are a few key safety issues:

- Chemicals may leach from the clay when heated. Traces of chemicals like phosphorus and sulphur can potentially get into the smoke stream when using a homemade polymer clay pipe.

- glazes and finishes intended for non-food surfaces may not be safe to smoke from. Special care should be taken to use food-safe glazes.

- Overheating the pipe could release fumes from the clay. Lower temperature bakes are recommended.

- Cracks or imperfections in the clay can harbor bacteria if not properly cleaned. Be sure to glaze surfaces and thoroughly wash pipes after use.

Given these potential risks, making an oven-bake clay pipe should only be attempted with great care. Proper safety precautions are a must.

Choosing the Right Clay

When making a clay pipe, it’s important to choose an oven-bake clay rather than an air-dry clay. Oven-bake clays are made from higher quality ingredients that can withstand the heat of an oven without cracking or breaking down. Air-dry clays contain more water and will not hold their shape when baked.

Oven-bake clays have properties that make them ideal for pipe making. They have low moisture content and a smooth, pliable texture that is easy to shape. Once baked, the clay hardens into a durable, ceramic material. Brands like Sculpey and Fimo are often recommended for small sculpting and modeling projects like pipes.

Polymer clays like Sculpey III and Premo are good oven-bake clay options. They have flexibility when conditioning the clay, allowing it to be shaped into hollow tubes and pipes without cracking. The smooth texture also creates a polished finish on the pipe after baking. Stay away from clays that are gritty or crumbly, as they will not hold up during the pipe making process.

Shaping the Pipe

Once you have chosen your clay, it’s time to start sculpting your pipe. Here are some techniques for shaping the different parts of a clay pipe:

The Bowl

The bowl is where the tobacco or other smoking material will be placed. Make the bowl an appropriate size and depth for your needs. Using your fingers, sculpt the clay into a rounded bowl shape. Use a chopstick or other tool to carve and refine the inside of the bowl.

The Stem

The stem is the long tubular piece extending from the bowl. Roll a piece of clay into a thick snake shape with your hands. Use your fingers to smooth out any irregularities and create an even thickness for the stem. Gently bend the stem into a curved shape.

The Mouthpiece

The mouthpiece is located at the end of the stem. Flatten one end of the stem with your fingers to create the mouthpiece. Refine the shape and thickness as needed so it is comfortable on the lips.

Take your time sculpting each part of the pipe. Allow the clay to dry slightly between shaping to avoid excess fingerprints marring the surface. Use sculpting tools as needed to refine details and create smooth finishes.

Baking Process

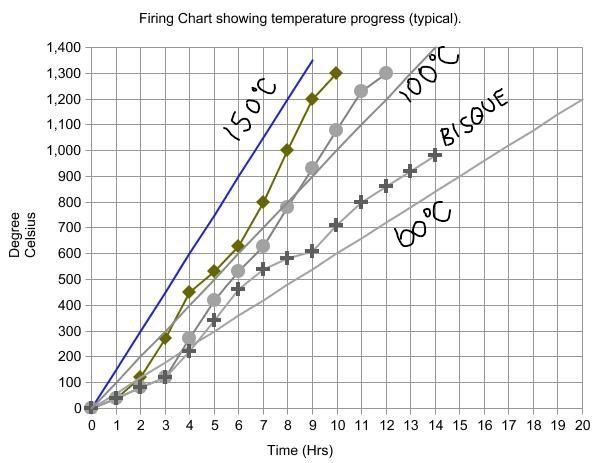

Proper baking is essential for curing oven-bake clay and avoiding cracks or bubbles in your finished piece. When working with oven-bake clay, follow the manufacturer’s instructions for baking temperature and times. In general, thinner pieces will require less time in the oven while thicker sculptures will need longer to fully cure.

A typical baking temperature for oven-bake clay is 130°C/275°F. Bake smaller pieces for 15-20 minutes, medium pieces for 25-40 minutes, and larger pieces for 1 hour or more. Check the clay packaging for more specific guidelines. If unsure, start with a lower baking time and check the clay regularly to avoid over-baking.

To prevent cracking or bubbling, preheat the oven fully before baking and avoid sudden temperature changes. Place the clay on a baking sheet lined with parchment paper or aluminum foil. Allow the clay to cool completely before handling after baking. Proper baking will result in clay that is fully hardened and durable.

Finishing Touches

Once the clay pipe has been baked and has cooled completely, you’ll want to smooth out any imperfections and properly seal it. Lightly sand any rough areas on the pipe using fine grit sandpaper. Be very gentle as you don’t want to remove too much material. Afterwards, wipe away any dust with a dry cloth.

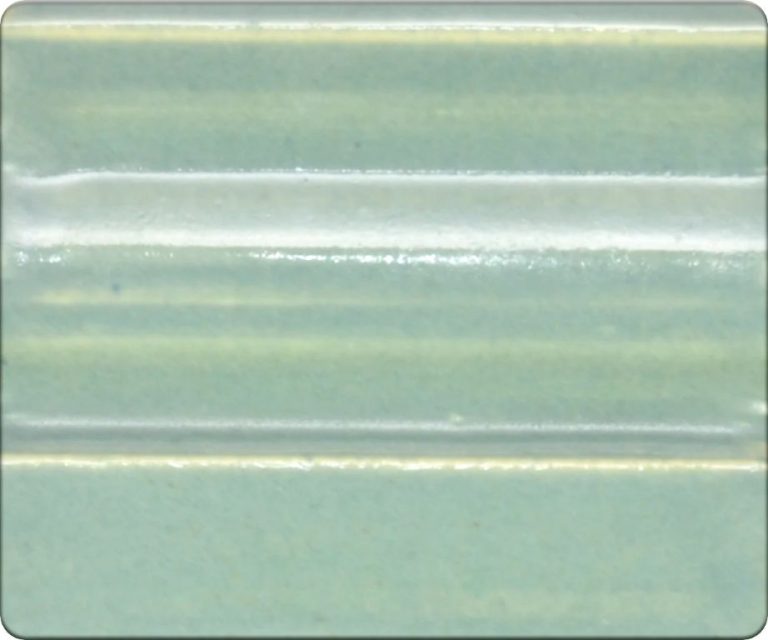

Apply a thin layer of acrylic sealer to the entire surface of the pipe. Allow it to dry fully. This will help waterproof it. You can optionally add decorative touches like glazing at this stage if desired. There are glazes specifically designed for oven-baked polymer clay. Brush the glaze evenly on the surface. Let it dry then bake the pipe again for 10-15 minutes to set the glaze.

Adding color and designs through glazing can really make your homemade clay pipe stand out. Glazes allow you to get creative with different colors, textures, and patterns. Some options include dripping, splattering, or dabbing the glaze on. Use painter’s tape to mask off sections. Or try layering multiple glazes for unique effects. The finishing touches are the perfect chance to put your artistic stamp on your clay pipe project.

Testing the Pipe

Once your clay pipe is complete, it’s crucial to test it thoroughly before use. This ensures it will function properly and safely as a smoking pipe.

First, check for air tightness and airflow. Hold the pipe up to your mouth and gently blow air through it. There should be good airflow with no leaks at the seams or elsewhere. Plug the ends and check that no air escapes. Air leaks can impact performance and allow hot embers to escape.

Next, assess durability and safety. Gently tap the pipe on a hard surface while holding it vertically and horizontally. There should be no cracks, chips or breakage. This tests the pipe’s sturdiness. Also check that all edges are smooth and rounded. Sharp edges can cut lips or fingers.

Additionally, ensure any glazes, paints or finishes are lead-free and non-toxic when heated. Consider having an independent lab test the pipe if unsure. Any risks or uncertainties means the pipe should not be used.

With thorough testing, you can feel confident your homemade clay pipe will function properly for stress-free smoking.

Maintenance

Properly maintaining your oven-baked clay pipe is important to keep it looking its best and functioning properly over time. Here are some tips for cleaning and caring for your pipe:

Gently wash the pipe with mild soap and warm water as needed. Avoid harsh chemicals or scrubbing, as this can damage the clay surface. Wipe down with a soft cloth.

Check periodically for any cracks, chips or scratches in the clay. Small flaws can be sanded down gently with fine sandpaper. For larger cracks or damage, the pipe may need to be re-baked to fuse the clay again.

Avoid dropping or banging the pipe, as this can cause chips or cracks. Clay is breakable, so handle the pipe with care.

When not in use, store the pipe in a secure place where it won’t get knocked around or damaged. Wrap in cloth or place in a storage box.

Over time, condensation from smoking can stain or discolor the clay surface. Gently clean with a soft bristled brush and mild soap as needed to remove residue.

If the pipe develops an odor, a baking soda/water paste can help absorb and remove smells. Rinse thoroughly after.

Avoid soaking or submerging the pipe in water, as moisture can damage the clay over time. Always dry thoroughly after cleaning.

With proper care and maintenance, an oven-baked clay pipe can last for years of enjoyment.

Pros and Cons of Oven Bake Clay Pipes

There are several advantages to using oven bake clay to make a pipe as compared to using traditional materials like glass or wood:

Benefits of Clay Pipes

Clay pipes are very durable yet lighter than glass pipes. They are less prone to breaking if dropped. Clay is also naturally heat-resistant so it holds up well when smoking. Since clay is porous, the smoke can be filtered and cooled as it passes through the material.

Clay pipes are highly customizable. You can sculpt any shape and design imaginable. The surface of the pipe can also be decorated with paints, glazes, or other embellishments before or after firing. This allows each pipe to be a unique handmade creation.

Clay is typically an affordable material, especially when working with basic air-dry or polymer clays. This makes clay pipes a budget-friendly option compared to imported glass pipes.

Clay is also a natural material that is more environmentally friendly than glass, which takes a lot of heat energy to produce. Making your own clay pipe reduces waste and environmental impact.

Drawbacks and Limitations

Clay pipes are quite fragile before they are fired in a kiln. The shaping, detailing, and decorating of the pipe requires a delicate touch before baking so it does not become misshapen.

Unglazed clay can be porous and prone to staining over time. A glaze should be applied before firing for a smoother more durable finish.

Clay also conducts heat. This means the pipe bowl and mouthpiece can get hot with extended use. Glazing the interior of the pipe or using a mouthpiece insert can help prevent this.

The size of the pipe is limited by what can fit in your oven or kiln. Larger pipes may require special facilities to fire properly. Complex shapes with overhangs or thin extensions may also be prone to cracking or slumping when fired.

Overall, clay pipes require some trial and error to perfect the shaping, glazing, and firing process. But the ability to create completely customized handmade pipes makes the extra effort worthwhile for many crafters.

Conclusion

In summary, it is certainly possible to create a functioning pipe out of oven-bake clay. The most important factors are choosing an appropriate high-fire clay, carefully shaping the pipe with an air channel, slowly baking at the right temperature, and properly finishing and glazing the pipe. Tested thoroughly, an oven-baked clay pipe should provide a safe, customizable smoking option. However, the process requires time, effort, and a willingness to experiment. Oven-baked clay pipes pose some advantages over glass or metal, but also come with drawbacks like fragility. Overall, clay pipe making can be a fun and rewarding DIY project for a crafty hobbyist, but isn’t necessarily worthwhile for the average person.