Do You Really Need A Kiln For Pottery?

Pottery and ceramics have fascinated humans for millennia. Archaeological evidence shows that pottery production began as early as 20,000 BCE in China, and independently emerged across cultures worldwide. The discovery of clay and development of early kilns allowed our ancestors to create beautiful and functional works of art.

The earliest known pottery kilns provide a glimpse into the ingenious engineering of past civilizations. For example, kilns unearthed in the Russian Far East date back over 9,000 years to the ancient Jomon culture, revealing advanced knowledge of firing techniques and temperature control (Source). Throughout history, the continuous refinement of kilns has enabled more complex forms, glazes, and artistic expression.

Today, potters have access to a dazzling array of electric and gas kilns. But an age-old question remains – is firing clay in a kiln an absolute necessity? Can beautiful ceramic art be created without this specialized equipment? Let’s explore the possibilities and limitations of crafting pottery without a kiln.

What is a Kiln?

A kiln is a high-temperature oven used to fire or bake clay and ceramic materials. The purpose of a kiln in pottery is to heat pottery to high temperatures in order to permanently harden the clay through a process called vitrification. Firing pottery in a kiln chemically transforms the clay so that the final ceramic ware is durable, waterproof, and stable.

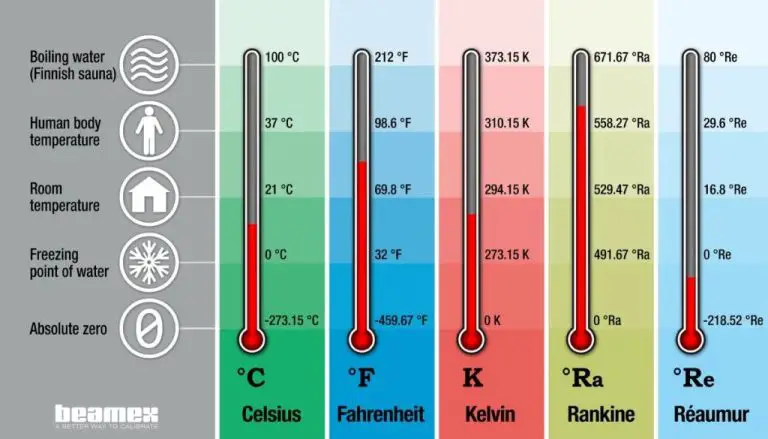

Kilns allow potters to reach temperatures between 1000°F to over 2400°F. At these high heat levels, chemical and physical changes occur in the clay that fuse and bond the silica and other molecules to create a hardened, finished ceramic material. Without the use of a kiln, pottery remains fragile, porous clay.

There are various types of pottery kilns, but all feature insulation and a heat source that allow the internal chamber to efficiently reach and maintain extremely high temperatures. Kilns protect pottery pieces from direct contact with flames while evenly distributing heat around the ware. This process of baking pottery at high heat in a kiln is essential for creating finished, usable ceramic items.

Types of Kilns

There are several main types of kilns used in pottery:

Electric Kilns

Electric kilns are very common for hobbyists and smaller-scale pottery production. They run on electricity and provide an even, consistent heat. The temperature can be precisely controlled. Electric kilns are often more affordable than other options and relatively simple to operate. However, they may be limited in size and take longer to fully heat up and cool down compared to gas kilns. Some popular models are from manufacturers like Nabertherm and Jen-Ken.

Gas Kilns

Gas kilns rely on natural gas or propane for fuel. They can achieve very high temperatures efficiently. Gas kilns heat up and cool down faster than electric models. The atmosphere and temperature can be precisely regulated. However, gas kilns are more complex to operate and maintain. The fuel source also makes them less portable. Gas kilns are common for large-scale industrial production.

Wood-Fired Kilns

Wood-fired kilns use wood as the heat source. This can create unique atmospheric effects on the pottery, like black carbon streaks, varied colors, and molten glaze textures. However, wood-firing requires diligent stoking of the fire over long periods. It can be more difficult to control the final results. Wood kilns are often used by artisans looking for one-of-a-kind effects.

Firing Without a Kiln

While having a kiln is ideal for firing pottery, there are some techniques potters can use to fire their pieces without a kiln. Some common methods include pit firing, raku firing, and firing in a simple campfire or bonfire. These alternative firing methods allow potters to achieve beautiful effects and harden their clay without investing in an expensive kiln.

Pit firing involves digging a pit in the ground, building a fire in the pit to heat surrounding surfaces, placing pottery around the edges of the pit, and carefully covering it all with fuel and debris for surface effects. Raku firing similarly utilizes an open fire fueled by propane or wood to quickly heat pottery placed on grates. Campfire and bonfire firing involve nestling pottery protected by sand or sawdust into the coals and embers of an open fire. With all these methods, temperature control can be difficult without a kiln.

While non-kiln firing can create interesting visual effects in a primitive or rustic style, there are limitations. It can be harder to reach and maintain temperatures hot enough to fully fuse and harden clay. Glazes also may not properly melt without adequate heat. The results can be unpredictable and have a higher chance of cracking or breaking. Proper placement in the fire is crucial. For potters who desire more consistency, better temperature regulation, glossy glazes, or versatile firing options, investing in a kiln becomes important. (Source)

Clay Types and Firing

There are several common types of clay used in pottery, each with different characteristics and firing requirements:

Earthenware: Earthenware clays are very common for beginner potters. According to thepotterywheel.com, earthenware clay is fired at lower temperatures, between 1000°F and 2100°F. It can be fired successfully without a kiln using methods like pit firing or raku firing. Earthenware absorbs water and is not fully vitrified. When fired, earthenware clay remains porous. Glazes are often used on earthenware to make it less permeable.

Stoneware: Stoneware clays require higher firing temperatures, usually between 2200°F and 2400°F. According to diamondcoretools.com, stoneware clay needs these high temperatures to fully vitrify and become non-porous. When fired correctly, stoneware is durable and water-resistant. Stoneware clays are common for functional pottery like mugs, plates, and bowls. The high temperatures required make a kiln necessary for properly firing stoneware.

Porcelain: Porcelain clays must be fired at very high temperatures, up to 2300°F or higher. According to soulceramics.com, porcelain can only be properly fired in a kiln able to reach these temperatures. Porcelain has a very fine texture and becomes perfectly smooth and glass-like when glazed and fired correctly. Porcelain clay is more challenging to work with than stoneware or earthenware.

The different types of pottery clay have specific firing requirements. While low-fire earthenware can be fired using alternative methods without a kiln, mid and high-fire clays like stoneware and porcelain require the high consistent heat that only a kiln can provide.

Kiln Firing Benefits

Kiln firing provides many benefits for pottery in terms of strength, durability, and effects compared to other methods like pit firing or firing with homemade kilns. According to Ceramic Arts Network, firing clay in a kiln results in more consistently heated pieces that are fully vitrified. The intense and even heat from an electric kiln allows the silica in the clay to fuse, making the material denser, less porous, and more durable.

Well-fired pottery that has been fully vitrified will be waterproof and resistant to scratching or chipping. Vitrification also improves the visual qualities of pottery by making glazes melt evenly and fuse to the clay body. This allows for brilliant colors and intricate effects. Kiln firing produces more professional and reliable results compared to alternative methods. It gives the potter precise control over the firing schedule and temperatures.

In summary, using a kiln results in pottery that is stronger, longer-lasting, and achieves superior artistic effects. The heatwork from a kiln transforms soft clay into a hard, durable material with an impervious surface. Kiln firing is essential for potters seeking to create high quality artworks and functional ware.

Artistic Effects

Kiln firing allows potters and ceramic artists to achieve a wide range of special artistic effects that would not be possible without the intense heat and controlled atmosphere of a kiln. Some of the unique finishes and surfaces only achievable through kiln firing include:

Crystalline glazes – These glazes contain zinc, fluorine, and other minerals that encourage crystal growth during firing. The crystals emerge on the surface, creating a shimmering, crusty texture. Crystalline glazes require precise firing up to around 2,300°F in an electric kiln. See reference

Metallic lusters – Lusters contain metal oxides like silver, gold, and copper that fuse to the glaze surface and become iridescent metallics after kiln firing. Lusters are applied after an initial bisque firing and require specialized kiln firing up to 1,600°F. The results are eye-catching metallic finishes.

Saggar firing – Saggars are enclosed containers made of clay or steel that protect pottery from direct flame or heat. Firing pottery in saggars allows smoke, vapor, and atmospheric effects. Many modern electric kilns have saggar inserts. See reference

Salt and soda firing – These ancient firing methods involve throwing salt, soda ash, or other materials into a wood-burning kiln to produce a crackled glaze surface and orange “fire stains.” Salt and soda firing range from 1,800°F to over 2,300°F. While challenging in a modern electric kiln, effects can be replicated. See reference

Overall, the intense and controlled heat of an electric kiln allows potters to explore unique artistic finishes not possible with low-fire techniques. From shimmering crystals to metallic lusters, kiln firing opens up a world of visual effects to enhance ceramic art.

Kiln Options

There are several factors to consider when selecting a kiln for pottery, including kiln type, size, power source, and cost. The main types of kilns used by potters are electric and gas-fired.

Electric kilns are the most common choice for home pottery studios. Small tabletop electric kilns start around 9 inches wide and can be powered with a standard household outlet. Larger electric kilns may require special electrical circuits or upgrades to handle the power load. Prices range from $200 for basic tabletop models up to $2,000 or more for large studios kilns. Electric kilns offer precise temperature control.

Gas-fired kilns can achieve higher temperatures but require ventilation. Prices range from $1,500 for small models to over $5,000 for large studio kilns. Gas kilns allow for more atmospheric effects with flame patterns. Popular sizes for home studios are 10-18 inches wide and 18-24 inches deep. Larger sizes may require special electrical upgrades or gas lines to be installed.

Other factors are size of pieces, desired firing temperature, and features like controllers and durability. Consulting pottery supply retailers like Seattle Pottery Supply can help match the right kiln with your goals and budget.

Final Considerations

When deciding on the right kiln, there are a few other factors to weigh as well:

Consider the size and shape of the kiln chamber. The dimensions need to adequately fit your largest pieces with some extra space. Look at oval, round or square options. Choosing a Pottery Kiln.

Factor in the durability and longevity of the kiln. Quality materials and craftsmanship result in better heat distribution and longer kiln life. The Ultimate Guide to Buying the Perfect Ceramic Kiln.

Consider any necessary venting requirements based on fuel type. Electric kilns need proper ventilation of fumes. Kiln placement needs fume hoods or chimney flues. The Ultimate Guide to Buying the Perfect Ceramic Kiln.

Factor in maintenance needs. Refractory brick or elements may require replacement over time. Ease of repair access aids maintenance. Choosing a Pottery Kiln.

Conclusion

In conclusion, while beginner potters can start without a kiln using air-dry clay, a kiln offers clear benefits for more serious pottery work. Kilns allow firing at higher temperatures to vitrify clay for strength, durability, and water resistance. They enable more control over firing effects like glazes. Kilns also provide consistency in results versus open-air firing. Still, beginners can learn handbuilding techniques and make small items from air-dry clay as an affordable way to start pottery as a hobby before investing in a kiln.

Ultimately, a kiln is not an absolute necessity but does enable greater capabilities and quality results when firing pottery. Much depends on the potter’s goals, commitment level, and type of pieces they want to create. With proper planning and technique, beautiful pottery can be achieved even without a kiln. However, as a potter’s skills grow, a kiln allows taking your pottery to the next level.