How Do You Dry Natural Clay Without Cracking It?

Properly drying clay is an essential step for clay artists and potters. If done incorrectly, clay can easily crack during the drying process, ruining pieces before they are even fired. Cracks formed during drying are often irreparable.

Fortunately, there are techniques artists can use to successfully dry natural clay without cracking it. The key is controlling the drying conditions and process. Proper drying involves gradually removing moisture from the clay at a slow, even pace to prevent stresses that lead to cracks. With care and patience, clay artists can reliably dry their pieces crack-free.

This guide will walk through the factors that cause clay cracking and provide tips to prevent cracks at every stage from wedging to drying and storage. With the right drying environment, methods, and monitoring, natural clay can be preserved without cracks. The goal is to arm potters with the knowledge needed to confidently dry their clay creations.

Causes of Cracking

Clay naturally shrinks as it dries, which can create internal stresses that lead to cracking. If some areas dry faster than others, this uneven drying can also cause stresses that crack the clay. Impurities in the clay, such as organic matter, can create weak spots more prone to cracking. The purity, makeup, and thickness of the clay body impacts how prone it is to cracking.

Preventing Cracks Before Drying

A very important step to drying clay without cracking is preventing cracks from forming in the first place before the drying process even begins. There are a few key methods to accomplish this:

Knead thoroughly to remove air pockets – Air pockets in the raw clay can expand during drying and cause cracks. Kneading the clay thoroughly during the initial sculpting process ensures the clay is smooth, uniform, and free of trapped air that could lead to cracks.

Avoid impurities – Any impurities in the clay such as small pebbles, organic matter, or lumps can lead to weak points where cracks start. Carefully remove any impurities while kneading and smoothing the raw clay.

Control thickness – Thick pieces of clay can crack more easily than thinner ones. Try to maintain an even thickness of 1/4″ – 1/2″ throughout the sculpture to reduce cracking during drying. Also avoid any thin protrusions or appendages that can be prone to cracking.

Drying Environment

The environment in which natural clay is dried can have a significant impact on cracking. The key is to create an environment that allows slow, even drying to occur.

Drying the clay in still air is recommended, as any drafts or fans can accelerate moisture evaporation from the surface, causing the exterior to dry faster than the interior. This differential drying rate results in cracks as the exterior shrinks while the interior is still saturated.

Maintaining a moderate temperature, around 70°F, is ideal. If it’s too cold, drying progresses very slowly, while excessive heat causes fast evaporation that can crack the clay. The ambient humidity can also be controlled to slow moisture loss.

In summary, a draft-free room at a comfortable temperature allows clay to dry gradually from the surface inward at a steady pace to minimize cracking.

Drying Methods

There are two main methods for drying natural clay without cracking it.

Air Drying

Air drying involves allowing the clay to slowly dry at room temperature over time. The benefits of air drying clay are that it is simple, low cost, and minimizes cracking if done properly. The drawbacks are that it can take weeks for the clay to fully dry. Air drying requires patience and vigilance to check the moisture levels and ensure even, gradual drying.

Commercial Drying

Using a commercial clay drying system with temperature and humidity controls allows much faster drying than air drying. Commercial drying can fully dry clay in hours or days rather than weeks. The benefits are faster throughput and predictable drying times. However, commercial drying requires more specialized equipment and energy input. Care must still be taken to ramp up temperature and humidity gradually. If dried too quickly, cracking can still occur.

Monitoring During Drying

Keeping a close eye on your clay during the drying process is crucial to preventing cracks. You’ll want to observe the clay regularly as it dries to catch any early signs of cracking. Check the clay at least daily, if not more frequently for pieces that are drying quickly.

If you notice any small cracks just beginning to form, wet your finger and run it over the crack to deposit some moisture. This rehydrates the clay and can help stop the crack from worsening. It’s much easier to fix a crack when it first starts rather than after it has extended deeper into the clay.

Make sure to pay extra attention to any corners, joints, or details in your clay piece that are prone to drying more quickly than other areas. Check these high risk zones frequently.

Monitoring the drying clay diligently and addressing any minor cracks as soon as they appear is key for avoiding larger cracks from forming as the drying progresses.

Fixing Cracks

If cracks do form during the drying process, there are ways to fix them. One method is to use water to rehydrate and seal the cracks. Take a small brush and apply water along the length of the crack. The water will soften the clay and help close the fissure. Continue applying water until the crack appears to be sealed. Allow the area to dry again slowly.

Another technique is to fill cracks with a clay slurry or slip. Mix some of the dry clay powder with water to create a thin, pourable mixture. Pour the slurry over the cracked area and allow it to seep down into the fissure. Let the patch dry completely. The slurry will harden in the crack and close it up. Sand the patch smooth once dry.

Preventing Recurring Cracks

Once your natural clay pieces have been fully dried, there are some additional steps you can take to help prevent cracks from recurring over time:

Seal the clay with an acrylic sealant or varnish. Applying a thin coat of acrylic helps protect the clay from moisture changes that could cause the clay to expand and contract, leading to cracks. Be sure to use an acrylic designed for clay, ceramic, or pottery. Apply according to the product directions.

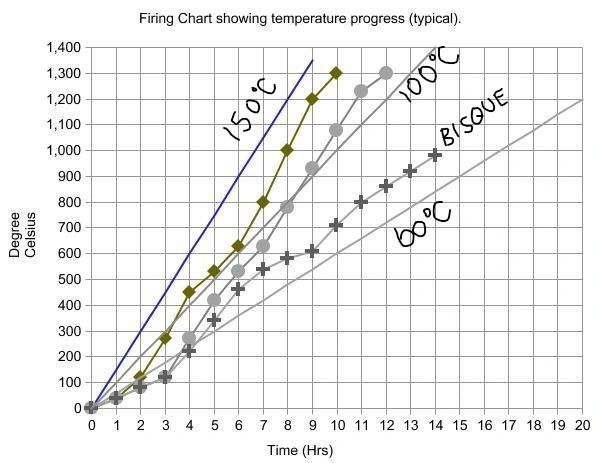

Fire or bake the finished clay pieces. Firing helps vitrify and further harden the clay, making it less porous and prone to cracking. Make sure to fire according to the type of clay, using the appropriate temperature and firing schedule. When fired at the optimal temperature, clay becomes much more durable. Consult your clay manufacturer for specific firing guidance.

Proper storage and display is also important. Keep fired clay pieces out of direct sunlight and avoid exposing them to moisture. Use felt pads or rubber bumpers on the bottom of sculptures to prevent surface scratches that can turn into cracks over time. Handle finished pieces with care.

By sealing, firing at the right temperature, and storing properly, you can help prevent cracks from recurring and extend the life of your clay artworks.

Storing Dried Clay

Once your clay is fully dry, it’s important to store it properly to avoid future cracking or damage. Here are some tips:

Wrap the dried clay in plastic to create a moisture barrier. This will prevent the clay from absorbing excess moisture from the air which can cause swelling and cracking. Make sure the plastic wrap is tightly sealed to lock out moisture. Placing the wrapped clay in a plastic bin or rigid box will also help protect it.

Avoid storing clay in areas with temperature fluctuations. Keeping your clay in an environment with a stable, moderate temperature around 70°F will help prevent expansion and contraction which stresses the clay. Don’t store clay next to heating/cooling vents, windows, or outside sheds subject to seasonal swings.

Conclusion

Drying natural clay properly to avoid cracking requires care, patience and the right techniques. Key things to remember are starting with the right clay consistency, drying slowly in a humidity-controlled environment, and monitoring throughout the process. While cracks may still occur, there are methods to repair them and steps to take to prevent future cracking. With the right diligent approach, natural clays can be dried to create lasting pottery and sculptures.

Rushing the drying process is one of the main reasons clay develops cracks. It’s important to have patience and allow sufficient time for the moisture to evaporate evenly throughout the clay body. Monitor the drying clay frequently and make adjustments to the temperature, humidity, airflow or drying method if needed. Preventing cracks in the first place is easier than repairing them later.

Additionally, care must be taken in handling and storing dried clay properly. Although drying is complete, clay remains sensitive to moisture and temperature changes which can still cause cracks if not stored correctly. With the techniques outlined, cracking can be minimized for successful drying and storage of natural clay.