How Is Clay Made?

What is Clay?

Clay is a naturally occurring material composed primarily of fine-grained minerals, which is generally plastic at appropriate water contents and will harden with dried or fired (Smithsonian 2022). The three main groups of clays are kaolinite, montmorillonite-smectite, and illite (Encyclopaedia Britannica). The most common types of clay used in manufacturing include:

- Kaolin – Also known as china clay, it is white in color and commonly used in ceramics.

- Ball clay – This is more plastic and has higher shrinkage than kaolin, making it useful for ceramic bodies and glazes.

- Bentonite – Has high plasticity and swelling ability. It is used for bonding foundry sand and as a sealing agent.

- Fire clay – Resists high temperatures and is utilized to line furnaces and fireplaces.

Clay’s properties that make it valuable include its plasticity when wet, hardness when dried or fired, and its ability to bond with other minerals. Key uses of clay include pottery, bricks, ceramics, cements, and as an industrial absorbent (Encyclopaedia Britannica).

Sources:

Smithsonian Institution. (2022). What is clay? https://www.si.edu/spotlight/what-is-clay

Encyclopaedia Britannica. Clay. https://www.britannica.com/science/clay-rock

Clay Formation

Clay is formed from the natural geological process of rock weathering and erosion. It begins when rocks like granite and feldspar are broken down into finer particles over time by exposure to the earth’s atmosphere and hydrosphere.

The primary cause of clay formation is the hydrolysis of feldspars. Feldspar is a name given to a group of rock-forming minerals that make up around 60% of the Earth’s crust. They contain aluminum, silica, oxygen, sodium, potassium and calcium. When feldspar comes into contact with water, it chemically weathers into kaolinite, which is the primary mineral component of clay. The water breaks down the crystalline structure of feldspar through hydrolysis, gradually releasing atoms which then reform into new clay minerals.

This weathering process happens most extensively in wet environments, which expedites the chemical breakdown of rocks. Environments such as streams, rivers, lakesides and tropical rainforests contain an abundance of clay deposits due to the constant exposure to water. The soil found in tropical rainforests is especially rich in kaolinite clays due to the warm and wet conditions.

Over geologic timescales, the continuing processes of physical erosion and chemical decomposition within these environments accumulate vast deposits of clay particles. These clay-rich sediments consolidate to form shale and mudstone sedimentary rocks, which can then be mined for use in ceramics and other industrial applications.

Sources:

https://quizlet.com/796526992/artd-150-quiz-flash-cards/

https://quizlet.com/650653509/ceramics-flash-cards/

Clay Composition

Clay’s composition consists of fine-grained minerals including silica, alumina, and water (Source). The most common clay mineral group is the kaolinites, which have a 1:1 layer structure. Other groups include the 2:1 layer clays such as smectites, illites, and chlorites. The particle size of clays is very small, less than 2 microns. This gives clay materials their characteristic plasticity when mixed with water, allowing them to be shaped. Different clay types have varying properties based on their precise mineral content. Kaolin clays contain a large amount of kaolinite and are very fine grained and less plastic. Ball clays contain 20-80% kaolinite along with other minerals and are very plastic. Fire clays are composed mainly of kaolinite and illite or chlorite, with moderate plasticity (Source).

Clay Extraction

Clay is extracted from the earth through surface mining or underground mining. Surface mining involves removing surface vegetation and soil to expose the clay deposits underneath. Underground mining involves accessing clay deposits by digging tunnels or shafts deep underground.

For surface mining, heavy equipment like bulldozers and excavators are used to remove the overburden. Once exposed, the clay is extracted by power shovels or draglines. Underground mining uses techniques like room and pillar mining to selectively extract clay while leaving structural pillars in place. Holes are drilled to place explosives for blasting and breaking up clay deposits.

After extraction, raw clay goes through various processes to remove impurities and achieve the desired properties. These include washing, blunging, sieving, magnetic separation, flotation, and centrifugation. Washing with water is commonly used to get rid of sand, silt, and other coarse impurities. Chemical dispersants may be added during blunging or high speed mixing. Sieving helps separate particles of different sizes. Other methods selectively remove specific contaminants.

Environmental considerations include minimizing land disturbance and reclaiming mined areas. Controlling water pollution from clay washing is also important. Dust and noise should be reduced around mining operations. Underground mining carries the hazard of ground collapses. Overall, sustainable mining practices that protect the environment are essential.

Sources:

YES GROUP – BALL clay Mining Process – YouTube

Clay Preparation

An important step in working with clay is properly preparing it before beginning to shape and form pottery or other objects. There are several key aspects of clay preparation:

Kneading – Clay is kneaded to remove air bubbles and evenly distribute moisture. Kneading by hand or with a mechanical pug mill makes the clay body uniform. According to Craft: pottery (puhu fa’i) (https://manyhands.org.au/resources/2013_projects/research_project_preservation_of_endangered_forms_of_fataluku_cultural_expr/fataluku/craft_and_tools_puhu_fai), kneading clay by hand takes considerable physical effort.

Slaking – Slaking involves soaking dry clay in water so it absorbs moisture and becomes plastic. The clay is worked and mixed as it hydrates. Getty Images notes that slaking is an important step before clay can be shaped (https://www.gettyimages.co.uk/detail/1411271279).

Drying and Reconstituting – Wet clay can be dried to make it stiffer and easier to transport. Dried clay is then reconstituted by soaking it in water again. The clay must be thoroughly dried initially to prevent cracking when reconstituted.

Additives – Materials like grog (ground fired clay) or colorants can be mixed into the clay body to achieve desired properties and aesthetics. A potter may test different additive mixtures to find the right blend for their project.

Shaping Clay

There are several techniques for shaping clay into pottery and other ceramic objects. The three main methods are:

Handbuilding Techniques

Handbuilding involves shaping clay without the use of a pottery wheel. Common handbuilding techniques include:

– Pinching: Pinching clay between the fingers and thumb to pull up walls and shape the clay.

– Coiling: Rolling ropes of clay into coils then stacking the coils to build up the piece. The coils can then be blended together.

– Slab building: Rolling out flat slabs of clay and cutting shapes that are stacked or joined.

– Molding: Pressing soft clay into plaster molds to create shapes.

Wheel Throwing

Wheel throwing involves shaping clay on a spinning pottery wheel. The centrifugal force of the spinning wheel allows the clay to be pulled up into vertical forms. Wheel throwing takes practice to master but allows for symmetry and uniform walled ware.Cal-Earth Ceramics Weekend Workshop A

Molding and Casting

Molds can be used to shape clay through press molding, pouring slipcasting, or pressing clay into plaster molds. Molds provide an easy way to repeatedly create identical shapes. Events

Clay Drying

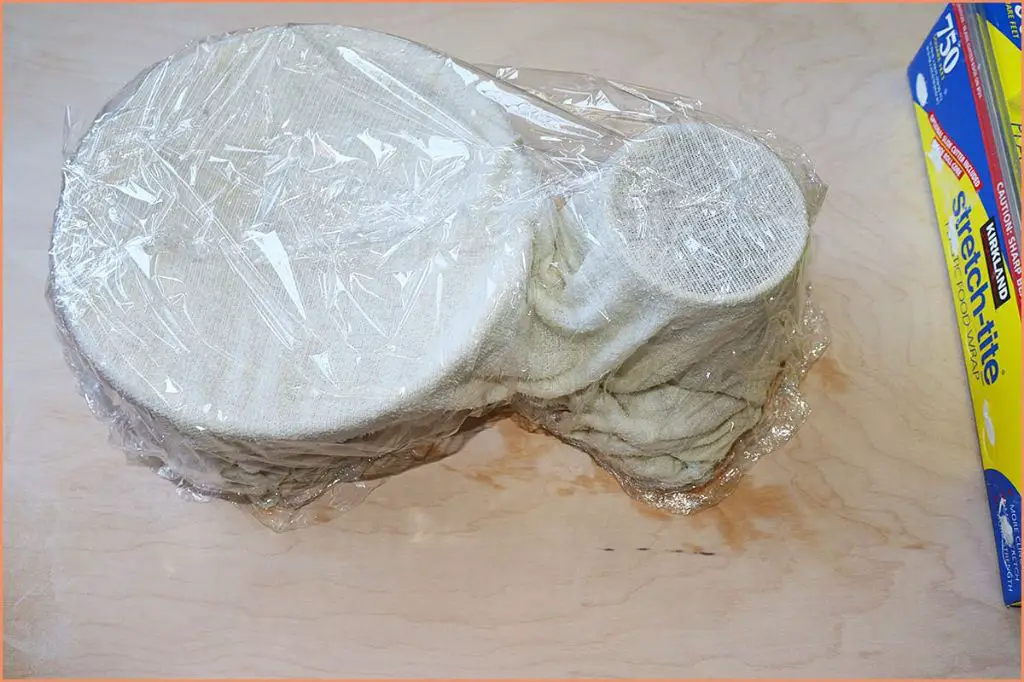

After shaping clay, the next step is drying it properly before firing. Air drying clay is the most common method. To prevent cracking, clay slabs or objects should be dried slowly and evenly. Thick areas take longer to dry than thin areas, which can cause cracks. Placing clay on porous materials like plaster or wood helps absorb moisture. Coating clay in plastic wrap or putting it in a damp box creates humidity to slow drying. Replace any absorbent materials often as they become saturated with moisture from the clay. Too rapid drying causes uneven shrinkage.

Using a drying room or kiln helps control temperature and humidity. Kilns remove moisture without overheating clay. Optimal conditions are 60-90°F and 50-70% humidity. Air circulation is also key. Some studios use industrial dehumidifiers to reach optimal conditions. Shelves with good airflow prevent clay from drying too fast. High humidity early in drying, followed by lower humidity prevents cracks. Consult kiln manuals for proper venting and time settings.

To prevent cracks, avoid drying clay in direct sun, near heating vents, or in breezy locations. Cool objects gradually once bone dry. Wrapping clay in plastic or damp materials can reintroduce moisture and reverse the drying process.

Firing Clay

Firing is an essential step in creating usable clay products. The purpose of firing clay is to permanently harden the clay body through a process called sintering, which bonds the clay particles together. Firing temperature has a significant effect on the final characteristics of the clay.

There are several common firing temperature ranges:

- Low-fire clays (cone 06-02) are fired between 1535-1640°F. Low-fire clays maintain their bright colors and are porous.

- Mid-range firing temperatures (cone 4-7) are between 1945-2232°F. Mid-range fires provide more durable products.

- High-fire temperatures (cone 8-10) range from 2280-2345°F. High-fire clays are non-porous and fully vitrified.

Kilns used for firing clay include:1

- Electric kilns that use heating elements to fire the clay.

- Gas kilns that burn natural gas or propane to provide heat.

- Wood-fired kilns that use wood as fuel for firing.

Glazes are used to color and decorate the clay surface. Glazes contain minerals that melt and form a glassy coating during firing. Applying and firing multiple layers of glaze produces effects like crazing, crawling, and breaking.

Clay Products

Clay is used to create a wide variety of products, from pottery and ceramics to industrial and environmental applications. Some of the most common clay products include:

Types of pottery and ceramics:

- Tableware like plates, bowls, mugs

- Decorative pottery like vases, figurines

- Tiles for flooring, countertops, and walls

- Bricks and roof tiles for construction

- Sanitaryware including toilets, sinks, and bathtubs

Industrial clay uses:

- Refractory bricks for lining high-temperature kilns and furnaces

- Cement production

- Oil well drilling

- Paint, rubber, and plastic production

- Paper coating and filling

- Iron ore pelletizing

Environmental clay applications:

- Clay liners for landfills

- Bentonite clay for containing pollutants

- Cat litter absorbent

- Oil and grease absorbent

Clay’s versatility allows it to be used in products that are part of our everyday lives, from dishware to industrial equipment. Advancements in clay processing continue to expand the different ways it can be utilized.

Future of Clay

The future of the clay industry looks bright, but there are some challenges around sustainability that need to be addressed. New technologies like 3D printing are opening up new possibilities for clay products and enabling more intricate and customized designs. However, clay extraction can disrupt ecosystems, so many companies are focusing on reducing their environmental impact through reclamation projects and more efficient mining techniques.

Supply issues may become a concern as high-quality clay reserves get depleted over time. The industry will need to invest in technologies that allow lower-grade clay to be utilized. Some firms are also experimenting with alternative materials that exhibit similar properties to clay.

To promote sustainability, recycling of clay products will become increasingly important. Some potters are using the technique of terra-cycling, where fragments of broken terra cotta are ground up and incorporated into new clay bodies. More opportunities exist for reclaiming clay from waste streams in other industries as well.

Overall, staying innovative with new technologies while addressing environmental and supply concerns through recycling and efficient extraction processes will enable the clay industry to keep growing in the future.

Sources:

https://www.scribd.com/document/521999765/Final-Report

https://pubs.lib.uiowa.edu/igsar/article/id/881/download/pdf/