How Long To Bake Polymer Clay Beads?

Polymer clay beads are a popular crafting material made from PVC resin mixed with pigments and plasticizers. The clay can be shaped and molded when raw. Once baked in an oven, it hardens permanently into a durable plastic bead.

Polymer clay beads grew in popularity in the 1990s and 2000s as an accessible medium for jewelry-makers and crafters. Their versatility and ability to achieve bright, stable colors and intricate designs makes polymer clay ideal for creating unique, handmade beads (Source). Polymer clay beads are now used worldwide to make jewelry, ornaments, dolls, and other decorative items.

To finalize polymer clay beads, they must be baked in a standard oven to cure the clay. Baking causes the beads to harden while retaining their shape. Proper baking time and temperature allows the clay to cure fully without burning. Typical baking temperatures range from 265°F to 275°F. The required baking time depends on the size and thickness of the beads.

Factors That Influence Baking Time

The main factors that influence how long to bake polymer clay beads include:

Clay Thickness and Size

Thicker and larger beads require longer baking times than thinner, smaller beads. This is because it takes longer for the heat to fully penetrate thicker clay. According to The Blue Bottle Tree, a good rule of thumb is to bake 1/4-inch thick beads for 15 minutes per 1/4 inch of thickness.1 For example, 1/2-inch beads would need 30 minutes. Thinner beads can be baked for as little as 10-15 minutes.

Clay Brand and Type

Recommended baking times can vary between polymer clay brands. Sculpey, for example, recommends baking most of their clays at 265°F for 15 minutes per 1⁄4 inch of thickness.2 However, Premo! polymer clay only needs to bake for 10-15 minutes per 1⁄4 inch at 275°F. Check the manufacturer’s instructions for exact times.

The clay type also matters. Translucent polymer clays may require longer baking than opaque clays to fully cure.

Oven Temperature

Higher oven temperatures allow polymer clay to cure faster than lower temperatures. However, too high can scorch the clay. Most brands recommend 275°F or lower. Always check the packaging. Additionally, oven thermometers are recommended since many ovens run hotter or cooler than their set temperature.3

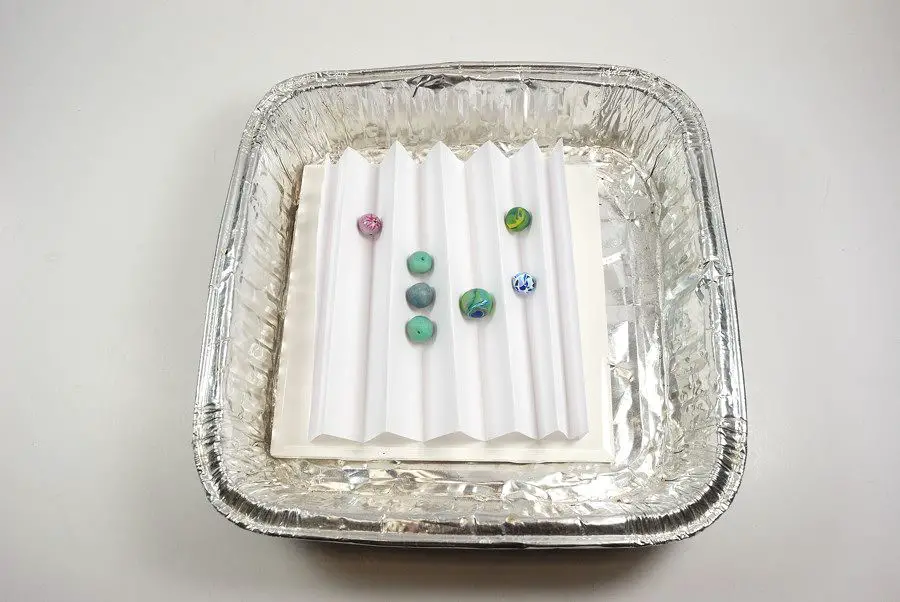

Baking Method

How the beads are arranged in the oven can impact heat circulation. Polymer Clay Earrings recommends baking beads on a dedicated baking sheet or glazed ceramic beads pan rather than directly on the oven rack. This allows heat to fully surround the beads for even baking.

General Baking Times

When baking polymer clay beads, the baking time will vary depending on the thickness and size of the beads. Here are some general guidelines for baking times based on bead size:

Thin/Small Beads

For thin or small beads that are less than 1/4 inch thick, bake for 15-20 minutes. Thin beads require less time in the oven to fully cure the clay throughout. According to Sculpey, baking times are typically 15-30 minutes per 1/4 inch of clay thickness (source).

Medium Beads

For medium sized beads around 1/4 inch to 1/2 inch thick, bake for 20-30 minutes. The increased thickness means the beads will require more time in the oven for the heat to fully penetrate the clay. As a general rule, add 5-10 minutes of baking time for each additional 1/4 inch of thickness (source).

Thick/Large Beads

For thicker or larger beads over 1/2 inch thick, bake for 30-60+ minutes. The thicker the clay, the longer the baking time needed to thoroughly cure the beads. Very thick beads may require baking for over an hour to ensure they are fully hardened throughout. Test larger beads by checking that the clay is rigid all the way through (source).

How to Tell When Beads Are Fully Baked

There are a few ways to determine if polymer clay beads are fully cured and baked through:

Visual Indicators

Fully baked polymer clay will have a uniform finish and high gloss sheen. The surface should be smooth and free of cracks or un-smoothed areas. Underbaked clay may have a matte, dull or chalky appearance. The color is rich and solid when thoroughly cured (Source).

Touch Test

Well-baked polymer clay beads feel hard and smooth to the touch. There should be no indentations when pressed firmly. Properly cured clay is solid yet flexible – it bends slightly rather than crumbling when pressure is applied. Underbaked clay will be sticky and leave fingerprints (Source).

Needle Test

Insert a needle into the thickest area of a bead. There should be some resistance without the needle poking through easily. A needle should not leave an indentation or mark in polymer clay that has been sufficiently baked. Fully cured clay will be firm enough that needle marks self-smooth (Source).

Baking Thin/Small Beads

Thin or small polymer clay beads that are less than 1/4 inch thick generally require 15-20 minutes of baking time. At high temperatures, thin pieces can overbake quickly, resulting in scorching or discoloration. To prevent this, bake thin beads at a lower oven temperature between 275-300°F. You can also tent foil loosely over the beads to help regulate the temperature.

Check for doneness after 15 minutes by touching the clay lightly. Properly baked polymer clay will be firm all the way through. Underbaked clay will still be soft or sticky inside. If needed, continue baking in 2-5 minute increments, testing frequently until the beads are fully cured. Let cool completely before handling.

Sources:

https://www.sculpey.com/blogs/blog/guide-to-making-polymer-clay-beads

https://www.polymerclayer.com/baking-polymer-clay.html

Baking Medium Beads

For polymer clay beads that are around 1/4-1/2 inch thick, a baking time of 15-30 minutes is typically recommended. According to Sculpey, medium sized beads should be baked at 275°F for 15 minutes initially, then for 5 additional minutes increments until fully cured (https://www.sculpey.com/products/baking-polymer-clay).

When baking medium sized beads, it’s important to use an oven thermometer to ensure the oven is maintaining the proper temperature. Polymer clay baking is very temperature dependent, and a thermometer can help avoid under or over-baking. Position the thermometer near where the beads will sit in the oven.

Rotating the pan during baking can also help beads cook evenly. Every 5 minutes, open the oven door briefly and turn the pan 180 degrees. This ensures even heat distribution as different areas of the oven may be hotter.

Baking Thick/Large Beads

Thicker beads, especially those over 1/2 inch, require longer baking times to ensure the polymer clay is fully cured. Thick pieces bake from the outside in, so the center needs ample time to reach proper baking temperature.

The Sculpey blog recommends baking for 15-20 minutes per 1/4 inch of thickness https://www.sculpey.com/blogs/blog/guide-to-making-polymer-clay-beads. For a 1 inch bead, bake for 60-80 minutes. For even thicker beads, extend bake times further.

To prevent cracking or exploding with extra thick pieces, bake at a lower temperature for longer. Try 250°F for 1-2 hours. Check frequently and stop baking once the clay is uniformly hardened.

Since polymer clay bakes from the outside-in, test thickness by inserting a thin tool like a toothpick into the thickest areas. There should be no indentations or sticky clay remaining when fully baked.

Cooling and Curing Polymer Clay Beads

After baking polymer clay beads, it is crucial to let them cool completely before handling or packaging them. Removing beads from the oven and immediately handling them can cause them to become misshapen or develop cracks. According to The Blue Bottle Tree, letting polymer clay cool completely after baking allows stress that built up during baking to dissipate, preventing cracks or breakage. Allow at least 15-30 minutes for polymer clay beads to return to room temperature before touching them.

It is also highly recommended to let polymer clay beads cure for 24-48 hours after baking and cooling. Curing allows excess moisture to evaporate from the clay and aids in forming strong, durable beads. According to Polymer Clayer, curing for 1-2 days after baking hardens the surface further and provides time for “post-oven polymerization and stress relief.” Cured polymer clay beads will be more scratch resistant, have better detail retention, be less porous, and have less risk of damage during use. Having patience and allowing for thorough cooling and curing produces higher quality beads.

Common Baking Issues and Solutions

When baking polymer clay beads, there are a few common issues that can arise:

Beads Cracking

Cracks can appear on baked polymer clay beads for a few reasons:

- Baking at too high of a temperature – Try lowering the baking temperature 25°F and baking for a longer time.

- Baking too long – Overbaking can cause beads to become brittle and prone to cracking. Carefully follow recommended bake times.

- Drastic temperature changes – Avoid exposing hot baked beads to cold water or cold surfaces as this rapid cooling can lead to cracks. Allow beads to cool gradually.

To avoid cracks, bake at the clay manufacturer’s recommended temperature and allow beads to cool slowly before handling.

Uneven Baking

If beads have raw uncured spots or scorch marks on one side, the oven temperature and bead placement likely led to uneven baking. Try these tips:

- Place beads in a single layer on the center oven rack.

- Allow space between beads for air circulation.

- Use an oven thermometer to check accuracy of temperature.

- Rotate pan 180° halfway through bake time.

Monitoring bead placement in the oven and adjusting as needed can help achieve an even bake.

Beads Stuck to Pan

Beads sticking to the baking pan or sheet is often caused by:

- Insufficient baking powder – Lightly dust pan with cornstarch or baking powder before baking.

- Baking too long – Overbaked beads may fuse to the pan surface. Follow recommended bake times.

- Baking on an unlined pan – Line pans with parchment paper or use a silicone baking mat.

Proper pan prep and bake times will prevent sticking.

Scorching

Black or brown scorch marks on beads are caused by:

- Baking temperature too high – Try reducing temperature by 25°F.

- Baking too long – Scorching can occur if bake time is exceeded. Use recommended times.

- Beads touching during baking – Allow space between beads for even heating.

Adjusting time, temperature, and bead placement will help avoid scorching.

Storing and Handling Baked Polymer Clay Beads

Proper storage and handling is important for preserving your baked polymer clay beads. Here are some tips:

For storage containers, opt for rigid boxes or trays that will prevent damage from bending or crushing the beads. Sealable plastic containers work well. Line boxes with tissue paper or foam to cushion the beads and prevent scratches (Source).

Keep storage containers in a clean, dust-free area to prevent debris from accumulating on the bead surfaces.

Avoid impacts during handling by not dropping containers or stacking heavy objects on top. Carefully move containers and don’t jostle beads around unnecessarily.

Inspect beads periodically and gently clean with a soft brush if needed. Baked polymer clay can last a very long time with proper storage and handling (Source).