Is All Polymer Clay Bakeable?

What is Polymer Clay?

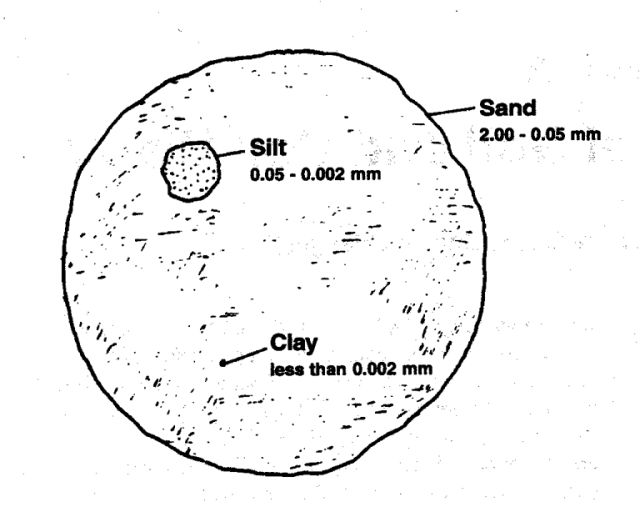

Polymer clay is a moldable clay that contains PVC resin and plasticizers which make it flexible when worked with. It maintains its shape after being baked in an oven. Originating in Germany in the 1930s, polymer clay became more widely available by the 1950s. The most popular brands today include Fimo, Sculpey, Premo, and Cernit.

There are two main types of polymer clay – oil-based and water-based. Oil-based clays are the most common and include brands like Sculpey and Fimo. They have an oil base which makes them soft and flexible. Water-based clays use water rather than oil. They dry to a matte finish and are often used for modeling and sculpting.

In addition to oil-based and water-based, there are also air-dry polymer clays. These clays do not require baking and will harden and cure at room temperature. They are made using PVA glue as a binder rather than oil or water.

Bakeable vs Air-Dry Polymer Clay

The main difference between bakeable and air-dry polymer clay is the method used to harden and cure the clay. Bakeable clays require heat to fully cure and harden. They are placed in the oven at temperatures typically between 130°F and 275°F. Air-dry clays cure and harden naturally at room temperature without heat.

Bakeable polymer clays offer some advantages over air-dry clays. They result in a more durable,stronger finished piece that won’t become brittle. Colors also remain truer and brighter when cured with heat versus air-drying. Many crafters find bakeable clays easier to condition and blend. There’s also a wider variety and selection of bakeable clays available.

However, bakeable clays require access to an oven which can limit portability for crafting on-the-go. They also use more electricity. The high oven temperatures can release fumes and odor during baking. Air-dry clays provide a more eco-friendly, versatile option for polymer clay crafts. Since they cure at room temperature, air-dry clays allow for portability and spontaneous crafting. The curing process is simple; no oven access or electricity is required. Air-dry clays also minimize unpleasant odors. The tradeoff is finished pieces may be more brittle and susceptible to breakage.

Most Common Bakeable Clays

The most popular brands of polymer clay that require baking to cure and harden are:

Sculpey – One of the first mass-produced polymer clays, Sculpey comes in a wide variety of colors and finishes like translucent, pearlized, and more. The standard Sculpey line cures at 275°F for 15 minutes per 6mm of thickness.

Fimo – Produced by Staedtler, Fimo has a smooth creamy texture and is available in colors like classic, effects, soft, and doll art. Fimo clays cure at 230°F for 30 minutes per 6mm of thickness.

Premo – From Sculpey, Premo features very vibrant colors and cures at 275°F for 15 minutes per 6mm. It is elastic when conditioned and holds fine detail well.

Cernit – A brand popular in Europe, Cernit has a very smooth finish and cures at 266°F for 15 minutes per 6mm. It has excellent durability and comes in specialty lines like Cernit Translucent.

Using Bakeable Polymer Clay

Bakeable polymer clay requires baking in an oven to fully cure and harden the clay. Follow the manufacturer’s instructions for proper baking times and temperatures. Most bakeable clays cure at temperatures between 130°F and 275°F for 10-30 minutes.

To bake polymer clay:

- Form your clay sculpture or project

- Place the finished piece on an oven safe surface like a ceramic tile or baking sheet

- Bake according to package directions, checking frequently near the end to prevent over baking

- Allow the clay to cool completely before handling

Bakeable polymer clay is ideal for detailed sculpting, jewelry making, decorative boxes, figurines, cake decorations, and any application where a strong durable finished piece is desired. The ability to fully cure the clay makes it suitable for functional items like mugs, handles, and other household objects.

Most Common Air-Dry Clays

There are three main types of air-dry polymer clays that are popular for crafting and modeling:

Modeling Clay: This type of clay is made from a mixture of water, oils, fillers and preservatives. The most common brand of modeling clay is Play-Doh. Modeling clays air dry slowly over time, allowing time for sculpting and shaping. They can be rewetted and reused multiple times.

Magic Clay: Magic clay is made from a mixture of polymers, oils and fillers. It feels like clay when wet, but hardens when exposed to air. Popular brands of magic clay include Fun Clay and Makins Magic Clay. Magic clay air dries quickly, so has to be used promptly before it sets.

Air-Dry Ceramic Clay: This is made from natural clays and ceramic materials mixed with polymer additives. It air dries into a hard, ceramic finish that can be painted and sealed. Common brands include Creative Paperclay and ACTIVA Air-Dry Ceramic Clay. The finished sculptures have a texture and solidity similar to real fired ceramics.

Using Air-Dry Polymer Clay

Air-dry polymer clay is very convenient to use since it does not require baking. However, it does take longer for air-dry clay sculptures to fully harden. The drying time can range from 24 hours up to 7 days depending on the thickness and size of the sculpture. To quicken the drying process, you can use a hair dryer on a low setting or place the sculpture in a warm spot with good airflow.

Air-dry clay is great for making jewelry, ornaments, figurines, and other decorative pieces. Because it air-dries, air-dry clay is perfect for projects with delicate parts that may get warped in the oven when baking. It also allows you to use materials like cardboard and tissue paper in the sculpture since they won’t burn during baking. Additionally, air-dry clay does not release fumes or odors like some bakeable clays do when cured in the oven.

Advantages of Bakeable Clay

Bakeable polymer clay offers some key advantages over air-dry clay that make it a popular choice for artists and crafters. Some of the main benefits of using bakeable clay include:

More durable – Bakeable clays go through a heating process that fully cures the material, making finished pieces much stronger and more durable than air-dry clay. This allows bakeable clay art to better withstand regular handling and last for years.

Higher quality finish – The baking process results in a uniform, professional finish for baked clay pieces. The colors stay truer and brighter compared to air-dry clays. Finished products have a porcelain-like look and feel.

More design options – Bakeable clays offer superior sculpting abilities. The consistency and texture enable more intricate shapes, finer details, and a wider array of effects. Artists can blend colors, achieve faux finishes, and create stunning polymer clay jewelry or figurines.

Disadvantages of Bakeable Clay

While bakeable polymer clay offers many benefits, it also comes with some drawbacks to consider. One of the main disadvantages is that bakeable clay requires baking. In order to cure and harden properly, bakeable clays must be placed in the oven and baked at the temperature and time specified on the packaging, usually for 15-30 minutes. This makes bakeable clay less convenient and accessible than air-dry clays that can harden at room temperature.

In addition, because bakeable polymer clay requires high heat to set, it’s not ideal for very large sculpting projects. The heat has difficulty penetrating to the center of thick sections, resulting in under-cured clay. Large sculptures are prone to cracking and damage during baking. So bakeable clays work best for smaller crafts and miniatures rather than big, bulky pieces.

Advantages of Air-Dry Clay

One of the biggest advantages of air-dry polymer clay is that it does not require baking. Air-dry clays will dry and harden at room temperature without the need for an oven. This makes air-dry clays easier and more accessible to use than traditional bakeable polymer clays.

Air-dry polymer clays also dry very quickly, usually within 24 hours or less. This allows crafters to complete projects faster compared to bakeable clays which require additional time for baking. The quick drying time is convenient when working on simpler projects or if you need something to fully harden faster.

Additionally, air-dry clays are often better suited for larger and more intricate projects. Since they do not require baking, there are less risks of under-baking thicker areas or having parts become damaged at high oven temperatures. Air-dry clays also reduce the possibility of getting cracks or imperfections that can occur when baking large clay pieces.

Disadvantages of Air-Dry Clay

While air-dry clay offers some benefits in terms of convenience, it also comes with some downsides compared to traditional bakeable polymer clay. Here are some of the main disadvantages of working with air-dry clay:

Less durable – Because air-dry clay cures through evaporation rather than baking, it produces a less durable finished product. Air-dry clay items tend to be more fragile and prone to breaking or chipping over time, especially if handled frequently or subjected to changes in temperature or humidity.

Limited design options – The air-drying process restricts what you can create with air-dry clays. For example, you can’t mix colors or achieve layered or blended effects like you can with bakeable clays. The items you make are limited to solid colors or simple hand-mixed blends.

Lower quality finish – Air-dry clays don’t tend to take finishes like gloss glazes or acrylic paints very well compared to baked polymer clay. The cured surface can repel paint and remains porous. Achieving a smooth, consistent finish requires more sanding and sealing.