Is Porcelain A Ceramic Or Plastic?

What is Porcelain?

Porcelain is a ceramic material made by heating raw materials like clay, quartz, and feldspar to high temperatures. It is known for its whiteness, strength, hardness, and translucency. Porcelain is sometimes referred to as “china” based on its origins in China. It first emerged in China during the Tang Dynasty around 600-900 AD.

Porcelain is considered a high-quality ceramic because it can be shaped very thinly while still retaining its strength. It has very low porosity, which allows it to be impermeable to liquids and resistant to staining. The main ingredients of porcelain are kaolin clay, potash feldspar and quartz. Kaolin clay gives porcelain its plasticity when mixed with water, while potash feldspar and quartz provide hardness and high temperature stability.

Some key properties of porcelain include:

- Whiteness – Porcelain can be made extremely white through the use of kaolin clay.

- Hardness – Porcelain is very hard due to sintering at high temperatures.

- Low porosity – Porcelain is impermeable to liquids because of its low porosity.

- Translucency – It can be translucent if made very thin.

- Brittleness – Porcelain is very brittle compared to other ceramics.

With its unique set of properties, porcelain has long been a coveted material used to make fine pottery, dishware, decorative objects and even dental prosthetics.

Porcelain vs ceramic

Porcelain and ceramic are both inorganic, nonmetallic materials typically made from clay and other minerals formed into objects using heat. However, there are some key differences between the two (source):

Porcelain contains kaolin clay, which allows it to become denser and less porous than ceramic. This makes porcelain harder, more durable, more stain-resistant, and better able to withstand freezing temperatures without cracking.

Porcelain also has a higher feldspar content than ceramic. Feldspar serves as a flux which allows porcelain to vitrify at higher temperatures. This results in a harder, less porous material.

The higher heat used in porcelain production results in less water absorption (less than 0.5% for porcelain vs. more than 0.5% for ceramic). This makes porcelain more impervious to liquids.

In summary, porcelain is a higher quality, more durable version of ceramic due to its denser composition and higher firing temperatures. It is harder, more stain resistant, and better for applications requiring water resistance.

How porcelain is made

Porcelain is made from a mixture of materials including kaolin, quartz and feldspar. Kaolin is a white clay that provides porcelain with its plasticity. Quartz gives it strength and feldspar acts as a flux to lower the firing temperature (Wikipedia).

The production process starts with the raw materials being crushed and washed to remove impurities. The kaolin, quartz and feldspar are then mixed together in the right proportions and milled into a slurry. The slurry is poured into molds to give it the desired shape. It is left to partially dry until it has a cheese-like consistency known as “leather-hard”. At this stage, the porcelain can be decorated before being fired at very high temperatures up to 1400°C to achieve vitrification and become fully hardened (Made How).

Firing is done in kilns and usually takes place in two stages – bisque firing and then glaze firing. Bisque firing partially vitrifies the body to a temperature between 1000°C to 1300°C depending on the type of porcelain. Glaze firing fully vitrifies the body and glaze together at temperatures between 1250°C to 1450°C to create the finished translucent, glass-like product.

Types of Porcelain

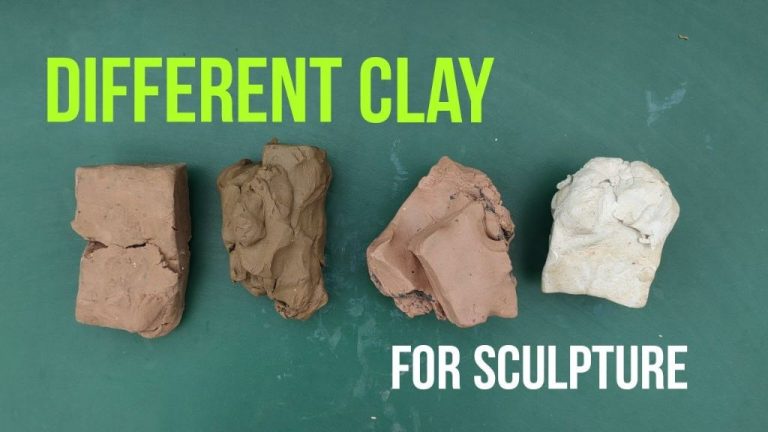

There are three main types of porcelain: bone china, hard-paste, and soft-paste:

Bone china is made from bone ash, kaolin, and petuntse. It was first developed in England in the early 19th century and is known for its high levels of whiteness and translucency. Bone china is highly desirable for its thin, delicate appearance but requires careful handling due to its fragility. It has a high level of vitrification, around 50-75%, and often contains at least 25% bone ash in its composition (Rau Antiques, 2022).

Hard-paste porcelain is made from a mixture of kaolin, quartz and feldspar fired at very high temperatures between 1,250°C and 1,450°C. It was first developed in China during the Tang Dynasty and later brought to Europe in the 17th century. Hard-paste is highly durable and vitrified, ideal for tableware and decorative objects. It has excellent whiteness and low porosity (Wikipedia, 2023).

Soft-paste porcelain uses glass as a flux instead of feldspar, firing at lower temperatures around 1,100°C. It was developed in Europe as an attempt to imitate Chinese hard-paste porcelain. Soft-paste is more porous and fragile than hard-paste but has a delicate, creamy appearance that was prized in the 18th century for figurines and decorative items (Wikipedia, 2023).

Uses of Porcelain

Porcelain has many uses, but some of the most common are for tableware, sanitaryware, and electrical insulators.

Porcelain’s smoothness, durability, and resistance to staining make it an ideal material for plates, cups, saucers and other tableware. It has been used for fine china dinnerware for centuries. Porcelain tableware is elegant and long-lasting.

In the bathroom, porcelain is valued for toilets, sinks, tubs and other sanitaryware. Its impermeable, non-porous nature makes it very easy to keep clean, resistant to stains, and hygienic. Porcelain’s durability allows it to withstand heavy usage in commercial and residential bathrooms.

Porcelain is also widely used to manufacture insulators used in electrical wiring. Its high mechanical strength and electrical resistance allow it to effectively insulate and protect electrical components. Porcelain insulators prevent short circuits and current leaks.

Advantages of Porcelain

Porcelain offers several key advantages over other materials like ceramic tiles or natural stone. Some of the main benefits of porcelain include:

Hardness:

Porcelain is extremely hard and durable. It has a hardness rating of about 7 on the Mohs scale, whereas ceramic is around 4-5. The high hardness makes porcelain very scratch and stain resistant, able to withstand heavy usage and traffic over time without showing significant signs of wear.

Source: The advantages and disadvantages of porcelain tile floors

Whiteness:

Porcelain can be made very white and bright, thanks to its purity and lack of iron oxide. The light color and glossy surface create a clean, elegant look. Porcelain’s bright white appearance stays true over time.

Translucency:

High quality porcelain can emulate the translucency and depth of natural stone. Modern porcelain production methods allow for translucency that mimics the look of marble and other stones.

Low porosity:

The dense composition and low water absorption of porcelain tiles make them very impervious to moisture. Porcelain resists water damage and staining from spills.

Source: 5 Advantages Porcelain Tiles over Ceramic

Disadvantages of porcelain

While porcelain tile offers many benefits, it also has some drawbacks to consider. One disadvantage is that porcelain can be more brittle than other types of ceramic tile. According to HGTV, porcelain’s dense composition makes it prone to chipping or cracking if subjected to blunt force or an impact. Care must be taken when installing porcelain tile to prevent cracks or chips.

Porcelain tile is also generally more expensive than regular ceramic tile. As Express Flooring notes, the high firing temperatures and specialized production methods required for porcelain tile increase costs compared to standard ceramic tile. While prices vary, porcelain tiles often cost $2-4 per square foot more than ceramic. The cost premium may be worthwhile for many due to porcelain’s durability and aesthetics, but the higher price should be considered.

Porcelain vs plastic

Porcelain and plastic are very different materials with distinct properties. Porcelain is a type of ceramic made from clay that is fired at high temperatures, while plastics are synthetic polymeric materials made from organic polymers like polyethylene, PVC, nylon, etc.

Some key differences in material properties between porcelain and plastic include:

- Porcelain has higher hardness and is more rigid and brittle, while plastics are softer and more flexible.

- Porcelain has excellent chemical and heat resistance, while plastics can degrade with chemical exposure and high temperatures.

- Porcelain has very low permeability and is non-porous, while plastics are more porous and permeable.

- Porcelain has higher density and is heavier than plastics.

- Porcelain is fully non-combustible, while plastics can burn.

- Porcelain is non-toxic, while some plastics can leach chemicals.

In summary, porcelain offers superior durability, heat/chemical resistance, and non-porous properties compared to plastics, but plastics offer more flexibility and lower weight. When choosing between the two materials, properties like the intended application, durability needs, exposure to heat/chemicals, and weight considerations play a key role.

Care and Maintenance

Porcelain is relatively easy to care for and maintain compared to other materials. Here are some tips for keeping your porcelain looking its best:

Cleaning

Most porcelain is safe to clean in the dishwasher, which helps remove stains and baked-on food. Use a gentle cycle and avoid overcrowding. For handwashing, use mild dish soap and warm water. Avoid abrasive cleaners or scrubbing pads, which can scratch the glaze.

Durability

Porcelain is highly durable, but not unbreakable. Avoid dropping it or knocking it against hard surfaces. High-quality porcelain may last for decades or longer with proper care. Repairs are possible for minor chips and cracks.

Repair

Specialty glues or porcelain repair kits can mend small chips and hairline cracks. Use painter’s tape to hold broken pieces in place during curing. For more serious damage, professional restoration may be required. Handle broken porcelain carefully to avoid further fragmentation.

Environmental impact of porcelain

Porcelain production does have some negative impacts on the environment. The firing process requires a lot of energy and can generate greenhouse gas emissions. Raw clay mining also causes land disruption. However, the industry is taking steps to improve sustainability.

Manufacturers are exploring ways to utilize more recycled materials in porcelain production. Using recycled glass, feldspar and metal oxides can reduce the need for virgin clay extraction [1]. Producing porcelain tiles with a higher recycled content can lower energy usage and carbon emissions.

There are also efforts to optimize manufacturing methods and kiln technology to minimize waste and maximize energy efficiency [2]. Porcelain can also be recycled after use, ground up and reused in new tiles or other applications.

Overall, while porcelain production does have environmental impacts, the industry is taking positive steps to improve sustainability through recycling, energy efficiency, and responsible manufacturing.