Is Porcelain A Good Conductor Or Insulator?

What is Porcelain?

Porcelain is a ceramic material made by heating raw materials like clay, quartz, and feldspar to high temperatures ranging between 1,200°C and 1,400°C (according to this video). The raw materials fuse together through sintering to create a dense, hard, and white ceramic material. Porcelain is known for its strength, hardness, whiteness, translucency, and resistance to chemical attack and thermal shock.

Porcelain consists of kaolin clay, quartz, and feldspar. Kaolin clay provides plasticity and strength. Quartz gives strength and structure. Feldspar acts as a flux to lower the melting temperature (according to the Prezi on porcelain chemistry). The combination of these materials allows porcelain to be shaped and fired at high temperatures to create the final product.

Porcelain has many uses including tableware, sanitaryware, electrical insulators, dental prosthetics, and decorative art objects. Fine porcelain in particular is used for tableware and decorative pieces due to its attractive white color and surface quality. The durability and non-porous nature of porcelain also makes it useful for sanitaryware and laboratory equipment.

Insulators vs Conductors

An insulator is a material that does not allow electricity to flow through it easily. Insulators have very high resistance to electric current. Examples of good insulators include glass, plastic, rubber, air, and wood. On the other hand, conductors allow electricity to flow through them easily. Conductors have very low resistance to electric current. Examples of good conductors include metals like copper, aluminum, and steel.

The key difference between insulators and conductors is their reaction to an electric field. When an electric field is applied, the free electrons in a conductor can move and transfer electric charge. In an insulator, the electrons are tightly bound to atoms and cannot move freely. This is why conductors can transmit electricity efficiently while insulators block the flow of electricity. Insulators have a much higher electrical resistance than conductors.

Fundamentally, the difference comes down to their atomic structure. Atoms of conductive materials have outer electrons that are loosely bound to their nucleus. This allows the electrons to become “free” and move between atoms when an electric current is applied. Insulators have tightly bound electrons in their outer shells that do not readily move between atoms.

Sources:

https://www.quora.com/What-is-the-difference-between-a-conductor-and-insulator-1

Is Porcelain an Insulator?

Porcelain has very low electrical conductivity making it an excellent insulator. Porcelain’s insulating properties come from its microstructure and chemical composition. Porcelain is made up of fine kaolin clay mixed with feldspar, quartz, and other minerals fired at high temperatures. This process creates a non-porous material composed primarily of glass with very low conductivity.

Due to its insulating properties, porcelain is often used to insulate electrical wires and components. Porcelain insulators help prevent current leakage and are resistant to electrical arcing. Many power line insulators are made of porcelain because it can withstand high voltages without conducting electricity. Porcelain has been used for over 100 years to insulate high voltage applications ranging from power lines to spark plugs. Its high strength, durability, and insulating properties make it well-suited for insulating electrical components.

Properties of Porcelain

Porcelain is made by firing a mixture of clay, quartz and feldspar at high temperatures between 1200-1400°C (2192-2552°F) [1]. This results in a hard, brittle, vitrified and glass-like ceramic material. Some key properties of porcelain include:

- Very hard and rigid – Porcelain has a high flexural strength and is highly resistant to chipping or breaking.

- Low porosity – The dense vitrified structure results in low permeability to water.

- White color – The raw materials and high firing temperature give porcelain its distinctive white color.

- Translucency – Porcelain is semi-translucent due to some light being able to pass through its glassy structure.

- Brittleness – While hard, porcelain lacks toughness and is prone to shattering if impacted.

- Poor thermal conductivity – Porcelain is a good thermal insulator and retains heat well.

- Electrical insulation – The vitrified structure makes porcelain an effective electrical insulator.

So in summary, the key physical properties of porcelain that distinguish it are its hardness, rigidity, low porosity, whiteness and translucency. It has a glass-like structure but is also brittle and prone to breakage.

Microstructure of Porcelain

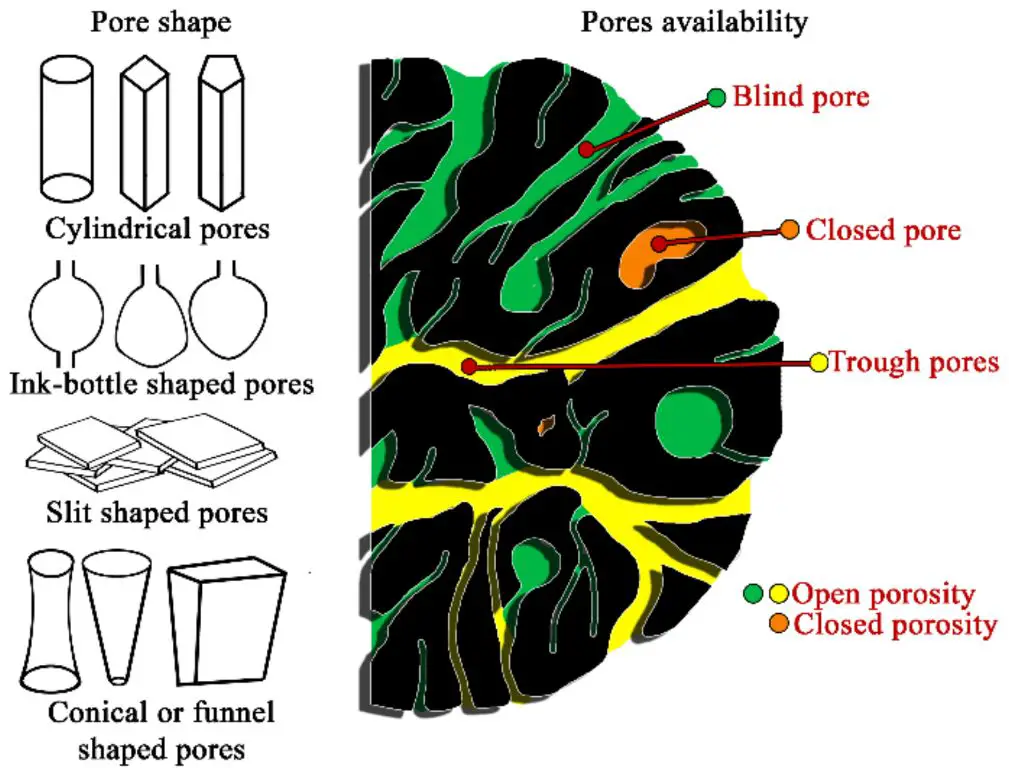

The microstructure of porcelain is what gives it excellent insulating properties. Porcelain has a very dense, non-porous structure comprised of fine grained minerals like quartz, feldspar, and mullite fused together through sintering at high temperatures (Romero, 2015). This dense microstructure results in low porosity, which reduces pathways for electrical conductivity.

Studies have shown that the microstructural characteristics of porcelain like grain size distribution and low porosity have a direct correlation with its insulating performance. Porcelain bodies with finer grains and lower porosity exhibit higher electrical resistivity (Martín-Márquez, 2010). The non-porous nature of porcelain makes it more resistant to electrical current flow when compared to materials with higher porosity and interconnected pores.

Overall, the dense, non-porous microstructure of porcelain is key to its effectiveness as an electrical insulator across many applications.

Comparison to Other Insulators

Porcelain has some key advantages when compared to other common insulator materials like glass and plastics:

Porcelain has higher mechanical strength than glass insulators. Glass insulators are prone to breaking under mechanical stress or impact. Porcelain’s dense structure makes it very durable and resistant to cracks or fractures. This allows porcelain insulators to better withstand impacts from debris or wildlife (Source).

Porcelain is also more resistant to chemicals than plastic insulators. Materials like polymer and fiberglass can be degraded by UV exposure or environmental chemicals over time. Porcelain’s inert composition prevents chemical reactions that could lead to damage. This gives porcelain insulators a longer service life compared to plastics (Source).

Applications as an Insulator

Porcelain is widely used as an electrical insulator due to its high resistivity and dielectric strength. Some of the common applications of porcelain as an insulator include:

Used to insulate wires and electrical components – Porcelain is an excellent insulator at high voltages so it is used to insulate wires and protect electrical components from short circuits. Porcelain insulators are ubiquitous in electrical substations, switchgear and transformers to insulate live parts.

Used as insulators in high voltage transmission lines – Transmission lines carry electricity over long distances at high voltages like 400kV. Suspension insulators made of porcelain are commonly used to suspend overhead high voltage power lines. The porcelain insulators provide the required insulation between the line conductor and the tower structure. (Source)

Porcelain bushings are used in transformers, switches and capacitors to bring out high voltage conductors through earthed metal walls while maintaining insulation. Porcelain insulators allow electrical equipment to operate reliably at high voltages.

Advantages of Porcelain Insulators

Porcelain insulators have several key advantages that make them well-suited for use in electrical applications. Some of the notable benefits include:

Withstands high temperatures – Porcelain can withstand very high temperatures, with melting points over 2,000°C (3,632°F). This high heat resistance allows porcelain insulators to function properly even when electrical currents produce intense heat.

Withstands high voltages – Porcelain is an excellent electrical insulator, able to resist the passage of electrical current even at extremely high voltages. Porcelain insulators can operate reliably at transmission voltages up to 800 kV.

Withstands high frequency vibrations – The rigid, dense structure of porcelain absorbs and dampens vibrations effectively. Porcelain insulators maintain their mechanical strength when subjected to the high frequency vibrations produced by alternating currents.

Resists weathering and pollution – Porcelain’s smooth glazed outer surface resists the buildup of moisture, dirt, dust, and other contaminants. The material is highly resistant to weathering and environmental degradation over decades of service.

Overall, porcelain’s unique combination of high heat resistance, dielectric strength, mechanical strength, and weatherability make it an ideal choice for insulating and protecting electrical equipment in demanding conditions.

Disadvantages of Porcelain

One of the main disadvantages of porcelain is that it is quite brittle and prone to cracking or chipping. The porcelain material has very low toughness and is not very resistant to mechanical or thermal shocks. Even small impacts or temperature changes can cause porcelain insulators to develop hairline cracks or fractures. This makes porcelain more susceptible to mechanical failure compared to other insulator materials like polymers or composites.

Another disadvantage of porcelain is its relatively heavy weight. Porcelain has a density of around 2.5 g/cm3, which means porcelain insulators are bulkier and heavier than insulators made of lighter materials. The heavy weight of porcelain insulators makes them more difficult to install and replace. It also increases the load on the structures supporting the insulators. For applications like transmission towers and poles, the weight of multiple porcelain insulators adds up significantly (Source).

Conclusion

Porcelain is an excellent electrical insulator due to its unique physical properties and microstructure. Porcelain is made from a mixture of clay, quartz, and feldspar fired at high temperatures which gives it a dense, nonporous, and vitreous structure. This prevents the flow of electric current. The lack of metallic impurities also allows porcelain to resist electrical conductivity. Furthermore, porcelain has high mechanical strength, hardness, and thermal shock resistance which makes it durable in high voltage applications.

In summary, porcelain is one of the most widely used insulators for electrical wiring and high voltage transmission lines. Its insulating properties come from its nonporous physical structure and lack of conductivity. Porcelain insulators prevent current leakage and resist weathering for long-term outdoor use. For these reasons, porcelain will continue being a go-to material in electrical and power engineering where effective insulation is needed.