Is Raku Firing Toxic?

What is raku firing?

Raku firing is a traditional Japanese technique for firing pottery that dates back to the 16th century. It was developed by the potter Chōjirō, who founded the Raku family of potters. The name “raku” comes from the Japanese word meaning “enjoyment” or “ease” (A Brief History and Guide to Raku-yaki).

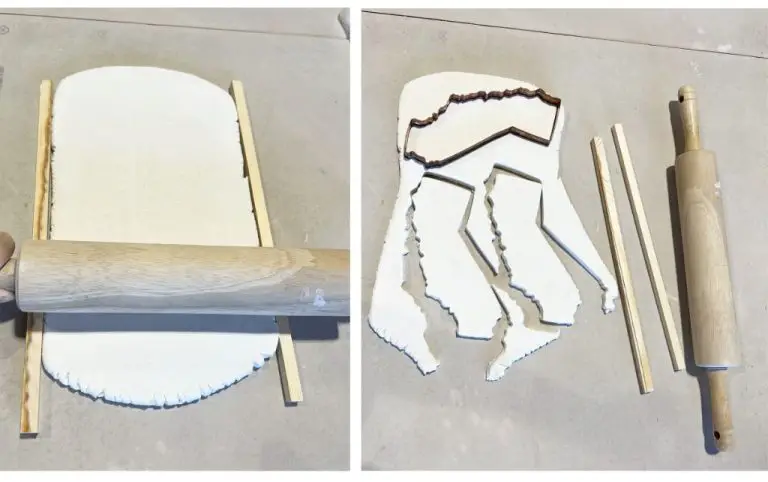

The raku firing process involves removing pottery from the kiln while it is still glowing hot and placing it into containers with combustible materials like sawdust or leaves. This produces effects like crackling and dark metallic lusters on the surface of the clay. The pottery is then placed into water or allowed to cool in the open air (History-Birth of Raku ware).

There are several types of raku glazes that create different effects. Bare raku relies on the natural terracotta clay color. Carbon black raku has carbon added to create a smoky black finish. Copper and other metal raku glazes incorporate metals to produce iridescent metallic effects (The Past and Present of Raku Firing).

Why there are toxicity concerns

Raku firing involves several steps that raise toxicity concerns. First, raku firing uses very high temperatures, often over 1800°F (982°C), to fully vitrify the clay body and fuse any glazes (https://digitalfire.com/glossary/raku). These high temperatures release toxic gases and particulates into the air that can be hazardous if inhaled.

Second, many traditional raku glazes contain lead, which vaporizes at high temperatures. Lead is a known neurotoxin and developmental toxicant (https://www.plantedtank.net/threads/toxicity-of-raku-pottery.122131/). When raku pots are fired, lead and other heavy metals can vaporize and be inhaled.

Finally, raku firing often involves a post-firing reduction stage where the hot pottery is placed in containers with combustible materials. This smoldering process produces billowing clouds of smoke that the potter is directly exposed to. Smoke contains many hazardous compounds like carbon monoxide, benzene, and fine particulate matter.

Potential toxins released

Raku firing can release dangerous toxins like lead and other heavy metals, carbon monoxide, and sulfur dioxide. According to Princeton University’s Office of Environmental Health and Safety, “Galena, cornish stone, crude feldspars, low grade fire clays, fluorspar, gypsum, lepidolite and cryolite can release toxic gases and fumes during glaze firings.”1 These materials contain heavy metals like lead that vaporize at high temperatures and can be inhaled.

The rapid cooling process of raku also produces carbon monoxide, a colorless, odorless gas that can cause nausea, fainting, and death in high concentrations. Raku glazes with high sulfur content release sulfur dioxide when fired, which causes breathing difficulties.

Prolonged exposure to these toxins, even in small amounts, can accumulate in the body over time and cause chronic health issues. Lead builds up in the bones and organs, sulfur dioxide irritates the respiratory system, and carbon monoxide reduces oxygen delivery to the body’s tissues.

Risks to the potter

One of the main risks to potters during raku firing is inhalation of toxic fumes emitted during the process. Certain materials like glazes with lead and organic materials can release dangerous gases like carbon monoxide and sulfur dioxide when subjected to the quick, intense heating of raku firing (Ceramic Arts Network, 2022). Lead oxide fumes are also a risk, which can cause blood and neurological issues with repeated exposure. Skin contact with lead glazes that emit lead oxide fumes can also occur during handling of freshly fired raku ware (Ceramic Arts Network, 2022).

The intense heat combined with possible airflow issues in a raku kiln can concentrate these toxic emissions, especially right when removing glowing hot raku pieces and placing them into reduction chambers. Studies have shown raku firing releases significantly higher emissions compared to other firing methods (Ceramic Arts Network, 2022). Proper ventilation, respirators, skin protection, and avoiding certain hazardous materials are key to reducing risks from toxic raku fumes.

Risks to the community

Raku firing produces smoke that contains toxic fumes and particulates, which can pose risks to bystanders if they inhale the smoke. According to Princeton University’s Office of Environmental Health and Safety, raku firing involves removing still-hot pottery from the kiln and placing them into combustible material like sawdust or leaves, which produces billowing smoke (citation). This smoke exposes anyone nearby, even if briefly, to carbon monoxide, sulfur dioxide, heavy metals, and large amounts of particulate matter (citation needed).

In addition to air pollution, raku firing can also lead to contamination of soil and water if the post-firing materials are not properly disposed of. The sawdust, leaves, and other combustibles used in raku firing collect potentially harmful substances like heavy metals that can leach into soil and water supplies if left out in the open (citation needed). Proper handling and disposal of raku firing waste is important to prevent environmental contamination that could impact the surrounding community.

Safety precautions

When raku firing, it’s important to take safety precautions to protect yourself and others from potential toxins released during the process. Here are some key precautions to take:

Use lead-free glazes. Lead glazes can release toxic fumes when fired, so opt for lead-free alternatives. According to the Ceramic Arts Network, lead-free glazes are readily available from most ceramic suppliers today.

Ensure proper ventilation. Raku firing should always be done outdoors or in a well-ventilated area. Fumes can be vented outside using a chimney or vent hood. Avoid breathing in smoke and fumes during firing and post-firing reduction.

Wear protective equipment. At minimum, you should wear safety goggles to protect your eyes from flare-ups. Respirators or protective masks should be worn to avoid breathing in toxic gases. Leather gloves, aprons, and kiln gloves will also help protect your skin.

Take all necessary precautions to protect yourself, any assistants, and the surrounding community when raku firing. With the right safety gear and adequate ventilation, the risks of toxicity can be minimized.

Alternative firing methods

While raku firing produces beautiful results, the process does release toxic fumes. Many potters are exploring alternative firing methods that are lower in toxins yet still achieve artistic effects. Some popular alternatives include:

Salt/soda firing

In salt or soda firing, common table salt or baking soda is introduced into the kiln during the firing process. The sodium in the salt or soda reacts with the clay and glazes to produce unique colors, textures, and effects. An added benefit of salt/soda firing is that it does not require highly toxic materials like those used in raku. According to Eastside Pottery, salt and soda firing is a greener, more sustainable approach while still allowing artistic expression (https://eastsidepottery.com/raku-firings/).

Pit firing

Pit firing involves building an open fire pit and carefully controlling the temperature by adding specific fuels at timed intervals. Natural materials like wood, sawdust, leaves, or even dried horse manure can be used. According to one source, pit firing produces effects similar to raku with smoky markings and fluid glazes, but avoids the toxic chemicals (https://mrsaartroom.weebly.com/clay–heat–smoke-alternative-firing-techniques–2016.html). With proper ventilation, pit firing can be a more natural approach.

Electric kilns

While electric kilns lack the dramatic effects of raku, they provide a much safer and healthier alternative. Electric kilns allow excellent control over temperature and atmosphere to achieve a wide range of glaze effects. According to potters online, careful glaze selections and techniques like wax resist can produce artistic outcomes without toxic chemicals (https://community.ceramicartsdaily.org/topic/18818-qotw-what-kinds-of-organic-materials-have-you-added-to-your-clay-or-glazing%C2%A0recently-please-specify-if-fired-by-electric-gas-wood-or-raku-in-oxidation-or-reduction/). With some creativity, electric kilns can be a safe raku alternative.

Greener raku practices

There are ways to make raku firing more environmentally friendly. Some ideas include:

Using fuel efficient kilns – Gas kilns can be designed for better heat efficiency so less fuel is wasted. This reduces emissions and cost (Cris Centi Ceramics, 2018).

Sourcing local materials – Using locally sourced materials like clay, glazes and fuels cuts down on transportation emissions. Glazes can be made from recycled glass. Hardwood charcoal can be sustainably produced (The Pottery Wheel, 2020).

Firing on a smaller scale – Raku firing smaller numbers of pieces at a time reduces fuel use and emissions. Small raku kilns are available to fire work one batch at a time (Digital Fire, n.d.).

With some adjustments, raku firing can be done in a more eco-friendly manner. The artistic effects are still achievable while lessening the environmental impact.

The future of raku

As concerns grow over the potential toxicity of traditional raku firing, many potters are looking for ways to innovate and improve the process. One major focus has been on developing new lead-free glazes that can still achieve the distinctive crackled effects that raku is known for. Glaze chemists like Stu Pagel, Justin Rothshank and Matt Katz have formulated recipes without lead, allowing potters to get vibrant results while avoiding hazardous materials (Raku Firing – the past and the present of the incredible …).

There is also a growing emphasis on community outreach and education around the safe practices for raku firing. Many experienced raku artists are taking steps to better control smoke and fumes during the firing process. They recommend firing in well-ventilated areas, wearing proper breathing protection, and avoiding proximity to populated spaces. Proper disposal of waste materials is also an important consideration (clayart – thread ‘raku and copper wire.’).

In terms of firing methods, some potters are experimenting with new ways to achieve raku effects that reduce potential toxins. Alternatives like saggar firing, pit firing, and vapor firing modify the traditional raku process to be more environmentally friendly. There are also new raku kilns that capture or convert emissions. While these innovations are still being perfected, they show the potential for raku to evolve into a greener process.

Conclusion

Raku firing produces harmful toxins that can pose health risks. The materials burn off can contain heavy metals and other compounds that are dangerous if inhaled. It’s important for potters to take proper safety precautions like wearing respirators, firing outdoors, and disposing of waste properly. While raku firing does have its risks, it can still be practiced responsibly with care taken to limit exposure. With proper handling, raku pottery can be created safely while keeping risks to both the potter and community low.

In summary, raku firing does release concerning toxins but potters have options to mitigate the dangers through developing greener practices. With extra care taken with materials and firing conditions, raku can be an artform that continues evolving in a healthier direction. While raku will likely always pose some degree of risk, awareness and prevention allows for responsible enjoyment of this traditional technique.