21 Types Of Concrete Blocks And How To Use Them (Pros And Cons)

There are numerous types of concrete blocks, each with its unique characteristics and applications. In this post, we’ll delve into 21 different types of concrete blocks, exploring their uses, benefits, and potential drawbacks. We’ll also provide some valuable tips on how to effectively utilize these versatile building materials. The versatility of concrete blocks lies in their ability to be used for various purposes, from construction to landscaping.

But before we dive into the specifics, let’s take a step back and understand what concrete blocks are all about. Concrete blocks have several advantages, including durability, sustainability, and cost-effectiveness. However, they also have some limitations, such as weight and transportation challenges. Despite these drawbacks, concrete blocks remain a popular choice for many construction projects. So, without further ado, let’s explore the 21 types of concrete blocks and their uses:1.

Bullnose Concrete Blocks: These blocks are characterized by their smooth, rounded edges, making them ideal for building exterior walls.2. Cellular Lightweight Concrete Blocks: With their lightweight composition, these blocks are perfect for reducing the overall weight of a structure while maintaining strength.3. Column Concrete Blocks: Designed to support heavy loads, column concrete blocks are essential for building foundations and pillars.4.

Concrete Bricks: While similar to regular concrete blocks, concrete bricks are smaller and more versatile, making them suitable for various construction projects.5. Concrete Corner Blocks: As their name suggests, these blocks are designed to fit snugly into corners, providing a seamless finish.6. Concrete Pillar Blocks: Similar to column concrete blocks, these blocks support heavy loads but with a focus on vertical applications.7.

Concrete Stretcher Blocks: Perfect for building foundation walls, stretcher blocks provide added stability and strength.8. Expanded Clay Aggregate Solid Construction Blocks: These blocks combine the benefits of expanded clay aggregate with solid construction, making them an excellent choice for building foundations.9. Fly Ash Blocks: With their lightweight composition and reduced waste generation, fly ash blocks are an eco-friendly option for sustainable construction.10.

Frogged Brick Concrete Blocks: Featuring a textured surface and unique design, these blocks provide an attractive finish for exterior walls.11. Hollow Concrete Blocks: While offering some benefits, hollow concrete blocks also have drawbacks, such as reduced strength and increased vulnerability to moisture damage.12. Jamb Concrete Blocks: Designed for use in partition walls, jamb concrete blocks provide added stability and support.13.

Light Aerated Concrete Blocks: With their lightweight composition and improved thermal insulation, these blocks are ideal for building foundations and exterior walls.14. Lintel Blocks (Channeled blocks): Perfect for creating arches and headers, lintel blocks offer an attractive finish and enhanced structural integrity.15. Partition Concrete Blocks: Ideal for dividing spaces, partition concrete blocks provide added stability and support for interior walls.16.

Paving Blocks: Suitable for outdoor applications, paving blocks are designed to withstand heavy foot traffic and harsh weather conditions.17. Scored Concrete Blocks: Featuring a textured surface with scored lines, these blocks provide an attractive finish for exterior walls and decorative elements.18. Solid Concrete Blocks: The most common type of concrete block, solid concrete blocks offer a strong foundation for various construction projects.19.

Split Concrete Blocks: Designed to be easily split along the diagonal, these blocks provide a convenient way to create custom sizes and shapes.20. Split Face Concrete Blocks: Featuring a textured surface with a natural, stone-like appearance, these blocks add an element of elegance to exterior walls.21.

Aerated Autoclaved Concrete Blocks (AAC): AAC blocks offer improved thermal insulation, reduced weight, and enhanced structural integrity, making them an excellent choice for building foundations. When choosing the right concrete block for your construction project, it’s essential to consider factors such as durability, sustainability, and cost-effectiveness.

By understanding the benefits and limitations of each type of concrete block, you can make informed decisions about which block best suits your needs.

What are concrete blocks?

Concrete blocks are a versatile building material composed of concrete, commonly employed in the construction of walls and foundations. Their adaptability stems from the diverse range of sizes, shapes, and colors they come in. Some popular varieties include cinder block, breeze block, and retaining wall block. As such, concrete blocks can be utilized for both residential and commercial projects, offering a practical solution for building structures.

Benefits of concrete blocks

Concrete blocks have emerged as a versatile and reliable building material suitable for a multitude of applications. Their remarkable strength and durability make them an ideal choice for load-bearing walls, foundations, and other structural components where weight-bearing capacity is paramount. Furthermore, concrete blocks boast impressive fire-resistant properties, rendering them an excellent option for firewalls, fire safety measures, and areas where high-temperature tolerance is essential.

The material’s ease of workability and adaptability to various surface treatments also contribute to its widespread appeal. As a result, concrete blocks have become a go-to material for builders seeking flexibility, resilience, and dependability in their projects.

Disadvantages of concrete blocks

While concrete blocks remain a widely used construction material, they do come with some notable drawbacks. One key limitation is their relatively low strength level, meaning they require reinforcement with materials like steel to be suitable for structures like buildings. Furthermore, concrete blocks are prone to cracking and crumbling over time, which can become a concern if proper maintenance is not carried out.

Additionally, the weight of these blocks can be quite substantial, making transportation and handling a challenging task.

What are concrete blocks used for?

Concrete blocks have long been a popular choice for construction projects due to their impressive strength and durability. These versatile building materials can be utilized in various applications, including foundations, walls, and floors. What’s more, concrete blocks are relatively easy to work with, allowing them to be cut or shaped to meet specific project requirements.

Types of Concrete Blocks and Their Uses.

Concrete block offerings can be overwhelming, with various options catering to different needs and preferences. While they share a common foundation – being made from concrete – each type boasts distinct characteristics that make them suitable for specific applications. Here’s an overview of the most prevalent types of concrete blocks:

Bullnose Concrete Blocks.

Bullnose concrete blocks are characterized by their rounded edges, which distinguish them from traditional square blocks. Their softer appearance makes them an ideal choice for accentuating other design elements or serving as the sole focus of a space. The organic feel they bring can be particularly effective in creating a cozy ambiance. The advantages of using bullnose concrete blocks are numerous.

For starters, they offer a more relaxed visual appeal that can be especially beneficial in contemporary or minimalist settings where sharp angles might not align with the desired aesthetic. Additionally, these blocks can help establish a connection to nature by introducing an organic element into your design. Another significant benefit is their ability to draw attention as a focal point.

The rounded edges of bullnose blocks tend to stand out more than other types of blocks, making them perfect for highlighting specific areas of your design. Furthermore, they are often more affordable than other concrete block options, which can be a major plus when working with a limited budget. Finally, the installation process for bullnose concrete blocks is relatively straightforward, even for those without extensive experience in working with concrete.

This ease of use can help alleviate concerns and make the design process much smoother.

Cellular lightweight concrete blocks.

Cellular lightweight concrete blocks are a unique type of building material that combines the benefits of traditional concrete with the advantages of foam technology. Made from a mixture of Portland cement, fly ash, water and foam, these blocks feature tiny air pockets that reduce their weight and make them ideal for use in earthquake-prone areas or other applications where reduced weight is important.

These blocks are also renowned for their exceptional insulating properties, making them an energy-efficient choice for both commercial and residential construction projects. By providing a barrier against heat transfer, they can help keep buildings cooler in summer and warmer in winter, ultimately reducing energy consumption and costs.

The benefits of using cellular lightweight concrete blocks extend beyond their insulation value.

They are also significantly lighter than traditional concrete blocks, making them easier to transport and handle on site. This can result in significant time and cost savings on a construction project.

In addition to their weight advantages, cellular lightweight concrete blocks possess excellent fire resistance and high compressive strength, making them an ideal choice for use in construction projects that require a high level of safety and durability.

Column concrete blocks.

Column concrete blocks, also known as masonry units, are a type of building material used in construction projects. These blocks are typically made from a mixture of cement, aggregate, and water, resulting in a smooth surface finish. Their primary application is in load-bearing structures such as walls and columns, where their strength and durability are particularly valuable.

Column concrete blocks come in a range of sizes, the most common being 16 inches long, 12 inches wide, and 12 inches tall. This standardization allows for easier planning and execution of construction projects.

So why choose column concrete blocks? For one, they are relatively straightforward to install, requiring no specialized skills or training. Additionally, their versatility makes them suitable for a variety of construction applications.

Furthermore, these blocks are renowned for their exceptional strength and durability, making them an excellent choice for both commercial and residential projects alike.

Concrete Bricks.

Concrete bricks are a versatile building material that offers numerous benefits. Made from a mixture of cement, water, sand, and gravel, they are strong and durable, making them suitable for use in walls, floors, and foundations. With their versatility, concrete bricks come in various sizes and shapes, including the most common eight inches by four inches, as well as six inches by twelve inches, with either square or rectangular designs.

Typically featuring a light gray color, they can also be dyed to create different hues. Additionally, concrete bricks have a smooth surface on all sides. In terms of advantages, concrete bricks offer a range of benefits that make them an attractive choice for construction projects. They are durable and long-lasting, requiring minimal maintenance and easy to clean. Furthermore, they provide excellent fire resistance, good insulation, and energy efficiency.

Notably, concrete bricks are also environmentally friendly, as they can be made from recycled materials and have a lower carbon footprint compared to other building materials. Lastly, their availability in various colors and styles allows for creative freedom when it comes to design and aesthetics.

Concrete Corner Blocks.

Concrete corner blocks are a crucial component in any masonry project, serving as a vital source of support for the corners of walls. Without them, structures would be significantly weakened and prone to collapse. These rectangular blocks, typically made of concrete, feature a central hole designed to accommodate rebar or other reinforcement, providing added strength. Prior to pouring concrete, corner blocks are strategically placed at wall corners to ensure stability and prevent shifting.

Once the concrete is in place, the blocks play a critical role in maintaining its integrity and preventing damage from external forces such as wind and seismic activity. Furthermore, concrete corner blocks can significantly reduce moisture-related issues by keeping water away from a building’s foundation.

In essence, these blocks are an effortless and economical means of safeguarding your home’s foundation, creating a solid connection between framing and the ground while resisting destructive forces.

Concrete Pillar Blocks.

Concrete pillar blocks play a vital role in construction projects by providing a sturdy foundation for buildings and structures. These large, solid blocks of concrete are available in various sizes and shapes, but their primary function remains the same: to ensure structural integrity. The right choice of block is crucial, as it can make or break the stability of a building. Fortunately, there are two main types of concrete pillar blocks to consider: precast and cast-in-place.

Precast blocks are manufactured in a factory and transported to the site for installation, while cast-in-place blocks are created on-site using molds. While both types have their advantages and disadvantages, precast blocks offer ease of installation, reduced labor costs, and lower risk of cracking or breaking during installation.

In contrast, cast-in-place blocks provide a more customized fit, can be made with reinforcement for added strength, but may require more effort to install and carry a higher risk of cracking. So, why opt for concrete pillar blocks? For one, they offer an attractive finish for basements or decks, available in various sizes that can be painted to match your home’s exterior.

Additionally, these blocks are durable, long-lasting, and easy to install – even DIY enthusiasts can accomplish the task within a few hours.

Concrete Stretcher Blocks.

Concrete stretcher blocks are a type of masonry unit designed for constructing walls. Measuring 16 inches long by 8 inches wide and tall, these blocks are typically laid with their longer sides facing horizontally. While they share this standard size, stretcher blocks can be obtained in various widths and heights to cater to different wall thicknesses.

These versatile building components offer a multitude of benefits when used in masonry projects.

Not only do they provide structural support and stability to walls, but they also enable designers to achieve diverse aesthetics. Some notable advantages of using concrete stretcher blocks include their ease of installation requiring no specialized skills or equipment, exceptional durability ensuring longevity, and the availability of different sizes and shapes to suit any project’s unique demands.

With such flexibility and practicality, it’s no wonder why concrete stretcher blocks are an essential component in many masonry projects.

Expanded Clay Aggregate Solid Construction Blocks.

Expanded clay aggregate solid construction blocks are a type of innovative building material that offers numerous benefits over traditional construction methods. Comprising lightweight, porous expanded clay aggregate, these interlocking blocks can be used to construct walls, partitions, and floors with ease. Their unique properties make them an attractive alternative for builders and homeowners alike.

Notably, they possess inherent fireproofing, waterproofing, and termite-resistance capabilities, eliminating the need for additional treatments or coatings. Furthermore, installation is straightforward, and maintenance requirements are minimal, making them a low-fuss, high-reward solution for construction projects.

Fly ash blocks.

Fly ash concrete blocks are a sustainable building material created by combining fly ash, a byproduct of coal combustion, with water and other ingredients. The mixture is then formed into blocks and allowed to cure. This eco-friendly alternative to traditional cement-based concrete has numerous benefits. One significant advantage is its reduced environmental impact, as it reuses waste materials that would otherwise contribute to pollution.

Furthermore, fly ash blocks possess exceptional strength and durability, making them suitable for a wide range of construction projects. The ability to customize the size and shape of these blocks further enhances their appeal, allowing builders to create structures tailored to their specific needs.

Frogged brick concrete blocks.

Frogged brick concrete blocks, commonly referred to as cinder blocks, are a type of masonry comprising concrete and coal ash. The distinctive frog-like shape is attributed to the frogging process. These versatile bricks have a multitude of uses, including construction, landscaping, and gardening. As a cost-effective and eco-friendly building material, frogged brick concrete blocks can be employed for various projects.

If you’re seeking an environmentally sustainable and long-lasting option for your next endeavour, consider utilizing these blocks.

The advantages of using frogged brick concrete blocks are numerous. They boast exceptional strength and durability, making them easy to install. Furthermore, they can be applied in a range of contexts, such as foundations, walls, floors, and more.

In addition to their functional benefits, frogged brick concrete blocks also offer an eco-friendly solution.

Manufactured from recycled materials, these blocks do not necessitate the use of chemicals or pesticides during production.

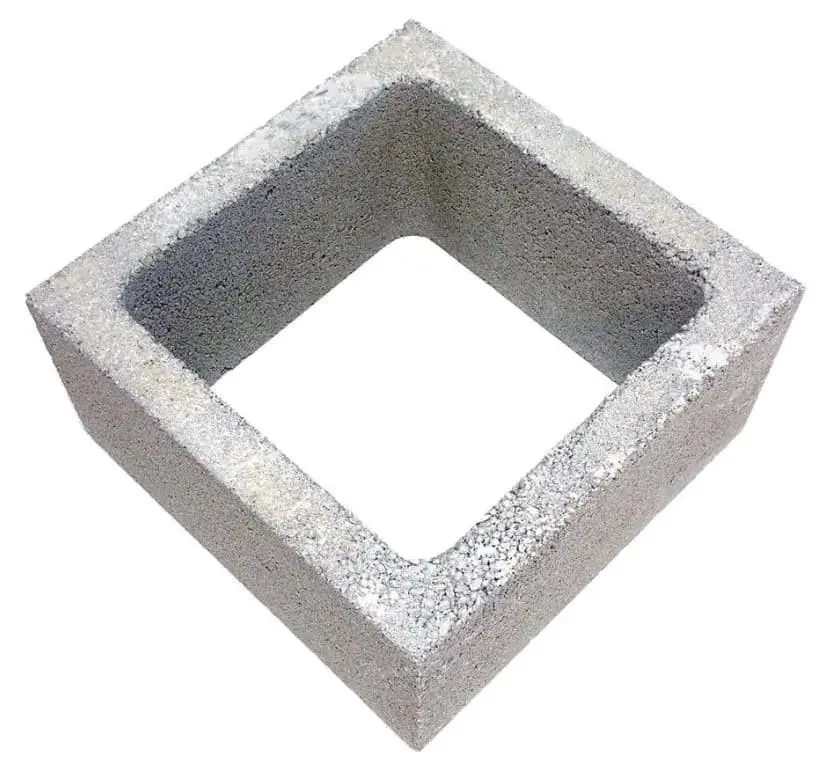

Hollow Concrete Blocks.

Hollow concrete blocks are a type of construction material that offers a unique combination of strength, durability, and versatility. They are typically manufactured by mixing Portland cement, water, and aggregate, resulting in a lightweight yet robust product. The popularity of hollow concrete blocks stems from their ability to be used for a wide range of applications, including walls, partitions, foundations, and more.

While they have several advantages, hollow concrete blocks also have some limitations. One of the main benefits is their ease of installation, which can significantly reduce construction time. They also provide good acoustic and thermal insulation, making them an attractive option for buildings that require a high level of comfort and soundproofing. Furthermore, they typically require less mortar than solid blocks, simplifying the construction process.

However, hollow concrete blocks do have some drawbacks. One potential issue is their increased susceptibility to moisture damage, which can compromise their structural integrity if left unchecked. Additionally, they may not be as strong as solid concrete blocks and are often not suitable for load-bearing walls.

Jamb Concrete Blocks.

Jamb concrete blocks are a staple in the construction industry, specifically designed for creating door and window openings in masonry walls. They also serve as horizontal supports, known as lintels, over these openings. These blocks are crafted by pouring concrete into molds. The versatility of jamb concrete blocks lies in their various sizes and shapes, with the most common being eight inches by 16 inches, although they can also be found in six-inch and 12-inch dimensions.

For added reinforcement, two or three rebar rods are typically embedded within the blocks. Jamb concrete blocks have a broad range of applications across residential and commercial construction projects. Their adaptability stems from their ability to be used in various contexts. In addition to creating openings in walls, they can also be employed as foundation footings or partitions.

On the plus side, jamb concrete blocks are renowned for their exceptional strength and durability, making them a reliable choice for builders. Installation is relatively straightforward, and these blocks are naturally fireproof and termite-resistant, reducing maintenance requirements. Furthermore, they boast a long lifespan with minimal upkeep needed. However, there are some drawbacks to consider. The upfront cost of jamb concrete blocks can be substantial.

Additionally, once installed, they can be challenging to remove if modifications or repairs become necessary. Lastly, improper installation can lead to cracking and chipping over time.

Light aerated concrete blocks.

Light aerated concrete blocks are a unique construction material composed of sand, cement, water, and an air-entraining agent. The mixture is then autoclaved, resulting in lightweight and low-density blocks. This innovative material boasts several benefits. One significant advantage is its significantly reduced weight compared to traditional concrete blocks, making it easier to transport and handle, thereby minimizing construction costs and time.

Additionally, light aerated concrete blocks exhibit excellent insulating properties, contributing to energy cost reduction. However, this material also has some limitations. While not as strong as traditional concrete blocks, they may not be suitable for all applications. Furthermore, the production process can be more expensive than traditional methods, offsetting potential savings.

Lintel Blocks (Channeled blocks).

Lintel blocks are concrete structures featuring a central channel, typically designed to support pipes or cables, but also suitable for other purposes. Their hollowed-out design offers several benefits over traditional solid blocks. For instance, lintel blocks are less prone to cracking or breaking, making them a more reliable choice. Furthermore, their construction enables easier cutting and drilling, streamlining the building process.

Lintel blocks have become a staple in various construction projects due to their unique advantages. While they may be more expensive than solid blocks, their strengths far outweigh any drawbacks. When installed correctly, lintel blocks can efficiently distribute load-bearing wall weight, providing added stability.

Partition Concrete Blocks.

Partition concrete blocks are a type of construction material used to create partition walls. These blocks are made from concrete and come in various sizes, allowing for the creation of internal as well as external partition walls. The versatility of partition concrete blocks lies not only in their ability to accommodate different spaces but also in their numerous advantages over other types of partitioning materials.

For instance, they offer exceptional durability, requiring minimal maintenance and care to last for many years. Furthermore, their ease of cleaning makes them an ideal choice for high-traffic areas. Moreover, the blocks can be customized to fit any space, making them a suitable option for both commercial and residential applications.

Paving Blocks.

Paving blocks, often made from concrete or stone, serve as a reliable means of creating durable surfaces for various applications. Ranging from functional pathways to decorative patios, these versatile pavers come in an array of shapes, sizes, and hues. Their versatility extends beyond aesthetics, as they can withstand heavy foot traffic and require minimal upkeep. One of the primary advantages of paving blocks is their ability to elevate the visual appeal of a property.

By installing them in areas like patios, walkways, or driveways, homeowners can create inviting spaces that seamlessly integrate with their existing décor. Additionally, these pavers are remarkably durable and easy to clean, making them an ideal choice for high-traffic zones. While paving blocks do offer several benefits, there are also some drawbacks to consider. The cost of these pavers can vary significantly depending on the material used, which may be a concern for those on a budget.

Furthermore, while installation is generally straightforward, it does require a bit more time and effort compared to other paving options.

Scored concrete blocks.

Scored concrete blocks are a unique building material that has been precision-cut to create a decorative finish. This versatile product is often utilized in landscaping, gardening, and construction projects, offering a range of possibilities for creative expression. Whether you’re looking to construct walls, fences, or other structures, or desire to add decorative elements like planters or benches, scored concrete blocks can be a valuable addition to your project.

While there are some potential drawbacks to using scored concrete blocks, the benefits far outweigh the limitations. For instance, these blocks offer unparalleled flexibility in terms of design, allowing you to create a wide range of styles and aesthetics. From sleek and modern designs to more traditional or rustic looks, scored concrete blocks can be molded to fit your vision.

Additionally, scored concrete blocks are remarkably durable and long-lasting, resisting damage from rot, insects, and wear and tear. However, it’s essential to consider the potential drawbacks before incorporating them into your project. The cost of these blocks can be higher than other materials, and they may require more maintenance over time. Furthermore, if you’re new to working with scored concrete blocks, you may encounter difficulties due to their unique characteristics.

Ultimately, the decision to use scored concrete blocks in your construction project depends on weighing the advantages against the disadvantages. With careful consideration, these blocks can become a valuable addition to your project, offering a unique and lasting touch.

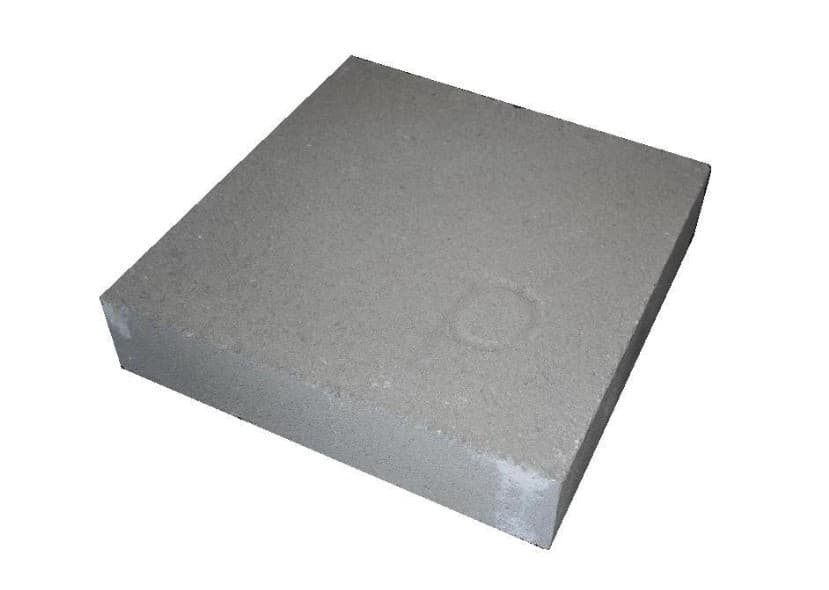

Solid Concrete Blocks.

Solid concrete blocks are a type of building material made from a combination of cement, sand, gravel, and water. The mixture is formulated to achieve a workable consistency, allowing it to be poured into molds or cast by hand. This robust material is commonly used in construction projects for walls, foundations, and structural elements, offering superior durability and strength compared to other block types like hollow concrete or cinder.

Notably, solid concrete blocks are less prone to cracking or crumbling over time. While solid concrete blocks have their advantages, they also present some drawbacks. On the plus side, they possess excellent fire resistance, termite proofing, and recyclability, making them an eco-friendly choice for homes in areas susceptible to these issues. However, their removal can be a laborious and costly process if needed for repairs or alterations.

Additionally, their considerable weight requires professional installation assistance. Furthermore, in regions prone to frequent earthquakes, solid concrete blocks might not be the ideal choice for foundation construction due to concerns over structural integrity.

Split concrete blocks.

Split concrete blocks, also known as cut concrete blocks, are a type of masonry material that has been halved to create a unique building product. They’re commonly utilized in paving and construction initiatives due to their versatility and strength. When it comes to weighing the advantages and disadvantages of split concrete blocks, several factors come into play.

One significant plus is their exceptional durability and strength, making them an excellent choice for projects that demand high load-bearing capacity, such as foundations or structural walls. Additionally, their ease of manipulation allows for seamless integration into any construction design. Cut concrete blocks can be effortlessly shaped or cut to accommodate specific spaces, rendering them an attractive option for architects and builders.

However, there are some limitations to consider when employing split concrete blocks. For instance, they may be challenging to locate in certain regions, which can hinder project timelines. Furthermore, their substantial weight and cumbersome nature can make them difficult to maneuver on larger projects, potentially leading to increased logistical challenges.

Split Face Concrete Blocks.

Split face concrete blocks are a decorative type of concrete block characterized by their textured, split faces. This unique feature is achieved by horizontally splitting the block into two pieces, resulting in one half with a smooth surface and the other half with a rough, split face. Typically used as exterior wall cladding or veneer on both residential and commercial buildings, split face concrete blocks offer an alternative to traditional smooth blocks.

Despite their unique appearance, which some find more visually appealing than smooth blocks, split face concrete blocks can be more challenging to work with. The rough surface of the blocks can make it difficult to achieve a clean, precise cut when trimming or shaping them, while also posing challenges for evenly applying mortar or grout. However, many individuals believe that the distinctive look of these blocks is worth the extra effort required to work with them.

Aerated Autoclaved Concrete Blocks.

Aerated Autoclaved Concrete (AAC) blocks are a type of precast concrete product composed of natural raw materials, first invented in Sweden in the 1920s. This unique material is a blend of Portland cement, lime, water, and an expansion agent like aluminum powder. Notably, AAC Blocks are significantly lighter than conventional concrete – weighing only about one-third as much – while still offering exceptional insulating properties.

The advantages of using AAC Blocks extend beyond their impressive physical properties. They are incredibly versatile, allowing for easy cutting, drilling, and shaping to meet the specific demands of any construction project. Additionally, AAC Blocks boast remarkable strength and durability, making them a reliable choice for both residential and commercial projects. Furthermore, they provide unparalleled fire resistance, insect-resistance, and protection against mold and mildew.

In terms of environmental benefits, AAC Blocks are an eco-friendly building material, made from natural resources with no chemical additives required during production. As such, they can significantly contribute to reducing the carbon footprint of your project, making them a sustainable option for conscious builders.

Factors to consider when choosing concrete blocks.

When selecting concrete blocks for a project, several factors must be considered. Weight is one crucial aspect, as different blocks have varying weights and it’s essential to ensure the chosen block can support the project’s weight requirements. Size is another critical factor, with the right block dimensions necessary to accommodate the project’s needs. Shape also plays a vital role, as the selected block must match the project’s design specifications.

Additionally, color is an important consideration, with the chosen block’s hue aligning with the project’s aesthetic goals. Finally, price is a significant factor, as the chosen block should fit within the project’s budget constraints.

FAQs about concrete blocks

Which block is best for construction?

When it comes to choosing the right building block, several factors must be taken into consideration. Climate, building type, and budget are all crucial elements to consider. While each material has its own unique benefits and drawbacks, concrete blocks are often a reliable choice for most climates due to their durability and ease of use. However, they can come with a higher price tag. Brick is another popular option that offers a more traditional aesthetic at a lower cost than concrete.

However, it may not be as durable in colder climates and can prove challenging to work with. Stone, on the other hand, boasts exceptional durability but often comes with a hefty price and added complexity in terms of installation. Wood, meanwhile, is a popular choice due to its ease of use and relatively low cost. Despite its limitations in terms of durability and susceptibility to insect damage or rot, wood remains a viable option for many construction projects.

What’s the difference between cinder block and concrete block?

Cinder block, a type of concrete masonry unit, is composed of Portland cement, aggregate (sand, gravel, or crushed stone), water, and admixtures. The blocks feature holes throughout and a smooth surface on both sides, with various sizes and shapes available. In contrast, concrete block, also known as hollow-core block, has no holes and a solid core. This difference in composition affects their applications and properties.

While cinder block is commonly used for walls in industrial and commercial buildings, concrete block is more often utilized in residential construction. Concrete block can be employed for both load-bearing and non-load-bearing walls. When using cinder block for load-bearing structures, reinforced blocks with steel rods or wire mesh are essential to ensure the necessary strength.

In terms of cost, cinder block tends to be less expensive than concrete block.

However, concrete block boasts greater durability and a higher fire rating. The former is more prone to water damage and may require sealing on all sides to prevent moisture from seeping into the holes. In contrast, concrete block is less likely to crack or chip.

Which is better hollow blocks or solid blocks?

While opinions may vary, the ideal choice between hollow and solid concrete blocks hinges on several factors. The intended application, environmental conditions, and personal taste all play a significant role in determining which option is most suitable. Some individuals swear by hollow blocks due to their reduced weight and increased workability, whereas others advocate for solid blocks because of their enhanced durability and improved soundproofing capabilities.

Ultimately, the best block selection will depend on the unique requirements and preferences of the individual or organization.

What are large concrete blocks called?

Cinder blocks, also known as ashlar blocks due to their composition of concrete and fly ash or bottom ash, are commonly employed in construction initiatives that require a robust foundation. Their versatility makes them an ideal material for building walls, supporting beams, or serving as posts in fences. Additionally, cinder blocks find applications in landscaping projects, such as constructing retaining walls or raised garden beds.

What is the difference between poured concrete and concrete block?

Concrete structures come in two primary forms: poured concrete and concrete blocks. Poured concrete is a mixture of cement, water, and aggregate (sand and gravel) that’s poured into molds and allowed to harden. The resulting solid mass can be molded into various shapes and sizes. In contrast, concrete blocks are manufactured by casting concrete into molds, which are then cured and cut into uniform blocks.

The primary distinction between the two lies in their installation methods: poured concrete requires the removal of forms once it has hardened, whereas concrete blocks are assembled by interlocking individual units. While poured concrete tends to be stronger than its block counterpart, both exhibit exceptional durability and a long lifespan. Poured concrete is frequently utilized for floorings and countertops, whereas concrete blocks are often employed in constructing foundations and walls.

Is concrete block a good foundation?

When contemplating concrete block as the foundation for your home, several key factors must be taken into account. Climate, soil type, and location all play crucial roles in determining whether this option is suitable. For instance, if you reside in an area prone to excessive moisture or rainfall, concrete block may not provide the necessary durability. Similarly, homes situated on sandy or loose soil might benefit from a different foundation solution.

Flooding-prone areas also pose unique challenges for concrete block foundations. On the other hand, those living in regions with moderate climates and stable soil conditions may find concrete block to be a reliable and effective choice.

Where and why blocks are used in construction industry?

Throughout history, blocks have been a cornerstone of the construction industry, offering numerous benefits that have cemented their place as a premier building material. With a legacy spanning centuries, blocks boast unparalleled strength, durability, and cost-effectiveness. While they are most often utilized in load-bearing walls, foundations, retaining walls, pathways, staircases, fireplaces, and chimneys, their versatility is truly remarkable.

By providing an incredibly secure structure that can withstand significant stresses, blocks have become the go-to choice for architects seeking a dependable foundation. Furthermore, their natural resistance to decay and weathering ensures they require minimal upkeep and can endure for decades.

The growing popularity of green construction projects has also seen a surge in block usage, as they offer exceptional thermal performance, making them an attractive option for environmentally conscious builders.

Conclusion

As we’ve explored various types of concrete blocks, it’s clear that each one offers unique benefits and drawbacks. Selecting the ideal block for your project is crucial, as it will impact the final result. To achieve success, it’s essential to dedicate time to researching and understanding the characteristics of different blocks. By doing so, you’ll be well-equipped to make an informed decision and find the perfect fit for your needs.

Related Posts

While pellet stoves can be an efficient and eco-friendly heating solution, they are often designed for smaller spaces or supplemental heat. However, some high-efficiency models can potentially warm a whole house, depending on factors such as the stove’s BTU output, chimney design, and home insulation. To determine whether a pellet stove can heat your entire home, consider the square footage of your space, the desired temperature, and the stove’s maximum capacity.

Additionally, it’s crucial to evaluate the stove’s airflow and ventilation system, as well as the overall condition of your home’s heating system. By taking these factors into account, you’ll be better equipped to decide if a pellet stove is the right choice for your heating needs.