20 Types Of Plywood And Grades Used In Interior And Exterior (With Pictures)

For many woodwork projects, plywood has been a reliable and affordable choice. However, with numerous types to choose from, it’s easy to feel overwhelmed. To make informed decisions, it’s crucial to understand the essentials of plywood shopping. In this post, we’ll delve into the world of plywood, covering its various types, important characteristics, and uses. From softwood to hardwood, exterior to marine, and more, we’ll explore everything you need to know about this versatile material.

Whether you’re a seasoned woodworker or just starting out, this guide will help you navigate the complex landscape of plywood.

Types of Plywood* Softwood Plywood* Hardwood Plywood* Aircraft Plywood* Exterior Plywood* Lumber Core Plywood* Marine Plywood* Overlaid Plywood* Structural Plywood* Tropical Plywood* Flexible Plywood* Construction Plywood* Veneer core plywood* MDF core plywood* ApplePly* Exterior sheathing plywood* Subfloor plywood* Sundeala boardWith so many options, it’s essential to consider factors like flatness, edges, size, and grade when choosing the right plywood for your project.

In this post, we’ll also explore what makes each type unique, from its uses to its strengths and limitations.

What is plywood?

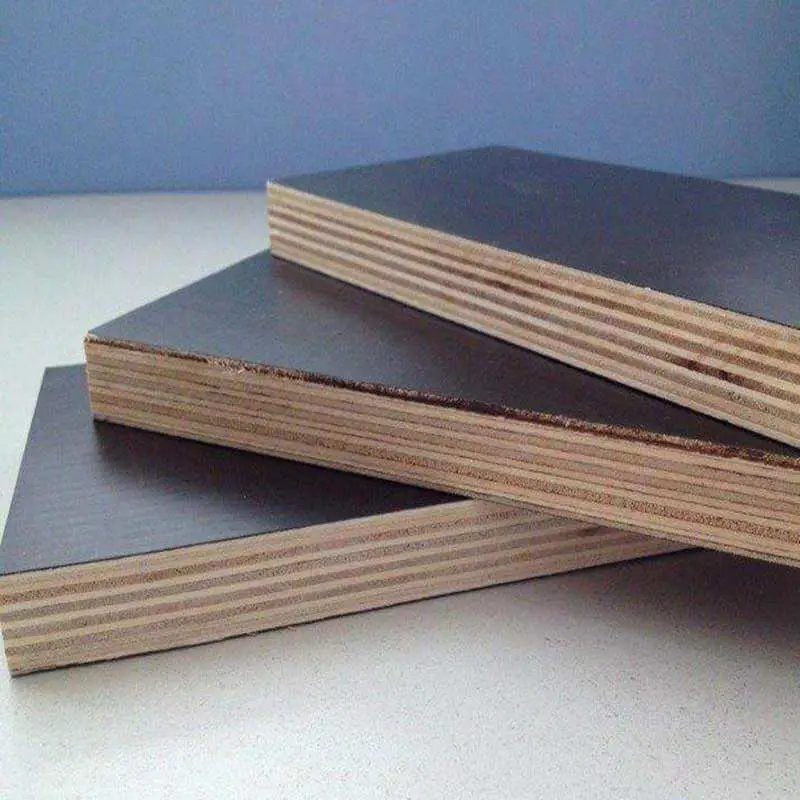

Plywood is a composite wood product that combines wood veneers from various sources, including hardwoods and softwoods. The veneer panels are typically glued together, although higher-grade plywood undergoes more complex processes involving heat and pressure to ensure a strong bond. Crucially, the angle at which the wood veneers are bound together is critical in preserving the natural grain patterns of the wood.

This attention to detail yields a product with a stable surface that resists moisture-related expansion issues. In contrast, 2×4 logs can be prone to warping and cracking when exposed to humidity, making plywood a more reliable choice. Furthermore, the manufacturing process imbues plywood with resistance to shrinking, breaking, and warping. The thickness of plywood is generally determined by the number of plies it consists of, with three-ply being the most common variety.

Sturdier options often feature five or multiple layers, offering increased durability.

17 Types of Plywood

When it comes to selecting the perfect plywood for your home project, it’s essential to have a solid understanding of the different types available. This requires more than just a casual glance at the options, as each type has its own unique characteristics that can impact the overall quality and functionality of your final product.

Softwood Plywood

Contrary to what their name may imply, softwood plywood is surprisingly versatile and durable. Despite being derived from softer woods like redwood, cedar, or pine, it’s often used in heavy-duty applications such as roof sheathing, subflooring for homes, and exterior framing. The flexibility of softwood plywood also makes it suitable for various DIY projects at home, including tool sheds, shelves, and even dog houses.

Hardwood Plywood

While walnut, oak, maple, and birch woods are the typical sources of veneers used to manufacture hardwood plywood, its unique characteristics set it apart from other types. With a minimum of seven layers, this type of plywood is renowned for its exceptional sturdiness.

Achieving this level of durability requires meticulous attention to detail during the manufacturing process, where veneers must be carefully glued at precise depths and angles to support heavy loads and demanding woodworking projects. As such, hardwood plywood is ideally suited for applications that require a robust frame, such as musical instruments, wood casings, sports equipment, and furniture construction, among others.

Aircraft Plywood

One of the most resilient and high-quality types of plywood is aircraft-grade plywood. Specifically designed from hardwoods such as birch and mahogany that are resistant to moisture and heat, this material excels in durability. In contrast, aircraft plywood is crafted with thinner wood veneers to maintain a lightweight and workable profile.

This unique characteristic makes it an ideal choice for constructing aircraft, rafters, boats, furniture designed to support heavy loads, and industrial-strength buildings that demand exceptional plywood performance.

Exterior Plywood

Exterior plywood, as its name suggests, is primarily used for outdoor construction projects. To withstand harsh environmental conditions, it’s manufactured with a special adhesive that’s resistant to water and weather. High-quality exterior plywood can support heavy loads for decades, making it an excellent choice for building sturdy frames. Interestingly, exterior plywood is classified as multi-ply, which means each sheet consists of multiple layers.

This construction provides added strength and durability. The fact that different regions experience varying climate conditions has led to oak exterior plywood gaining popularity among builders, as it’s particularly effective in humid environments where mold and mildew growth are more common.

Lumber Core Plywood

3-ply plywood is crafted by combining a sturdy wood core with two thin layers of hardwood veneer on either side. The outer layer typically features premium hardwoods like birch, maple, or oak, while the inner layers are comprised of strips of softwood carefully glued together to form a robust wooden slab. This unique construction allows for a softer interior, making it ideal for applications where nails and screws will be used.

While this design offers greater versatility, it also presents a risk: if the wrong type is chosen, the fasteners may not provide a secure hold.

Marine Plywood

While marine-grade plywood may be marketed as water-resistant, it’s essential to understand that this term refers more to the quality of construction rather than the material itself being impervious to moisture. What sets this type apart is its lack of knotholes, making it a popular choice for exterior applications.

Typically crafted from firwood or larch, marine-grade plywood boasts exceptional durability and sturdiness.

However, it’s manufactured without the use of chemicals, leaving it vulnerable to rot, mildew, and mold growth. Despite this limitation, its natural resistance to decay makes it an ideal choice for exterior structures like plant boxes, benches, decks, and gazebos.

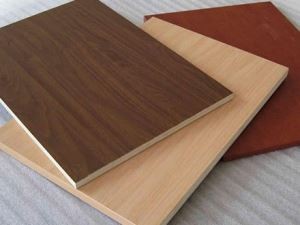

Overlaid Plywood

Overlaid plywood earns its name from its distinctive surface treatment, which presents a rich, wood-finish appearance. The manufacturing process mirrors traditional plywood construction, involving the lamination of wood veneers with waterproof adhesives. However, overlaid plywood is available in two densities: medium and high. The key difference lies in the bonding process, where wood veneers are subjected to high heat and pressure conditions.

This results in a more expensive product, as higher resin levels are required for the high-density variant. Interestingly, the smooth finish on the surface serves a functional purpose rather than purely aesthetic one. By creating an impermeable barrier, the overlaid plywood effectively repels dust, water, and other particles that might otherwise compromise its integrity.

This added durability also renders it scratch-resistant, making it a reliable choice for applications where resistance to wear and tear is crucial.

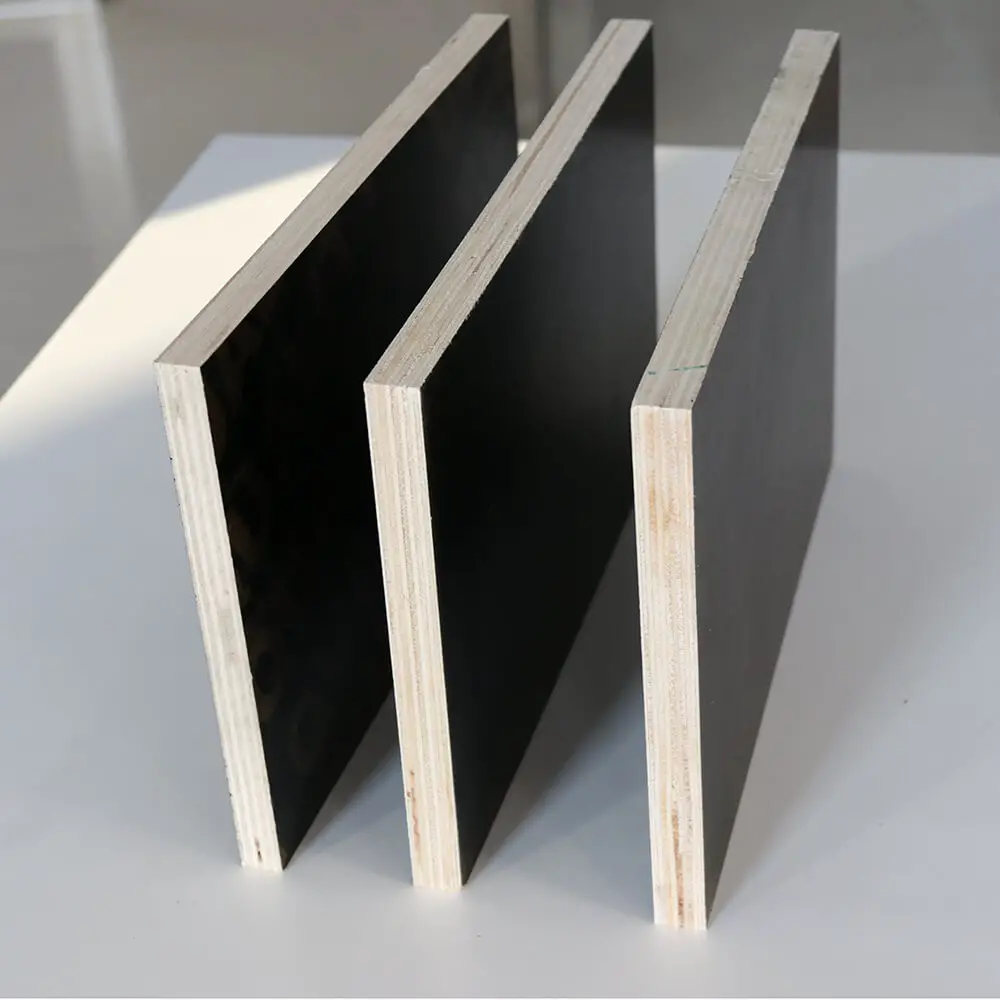

Structural Plywood

Structural plywood, also referred to as sheathing plywood due to its exceptional durability in framing and building applications, relies on the use of robust and waterproof adhesives during manufacturing. The products are typically classified as C or D grades, reflecting their strength and resistance to moisture.

While these materials are remarkably durable, they cannot be upgraded to higher grades without increasing production costs, making them a cost-effective solution for construction projects.

Despite its limitations in handling harsh weather conditions, structural plywood remains a popular choice for both indoor and outdoor woodworking projects, offering a reliable and long-lasting material for various construction needs.

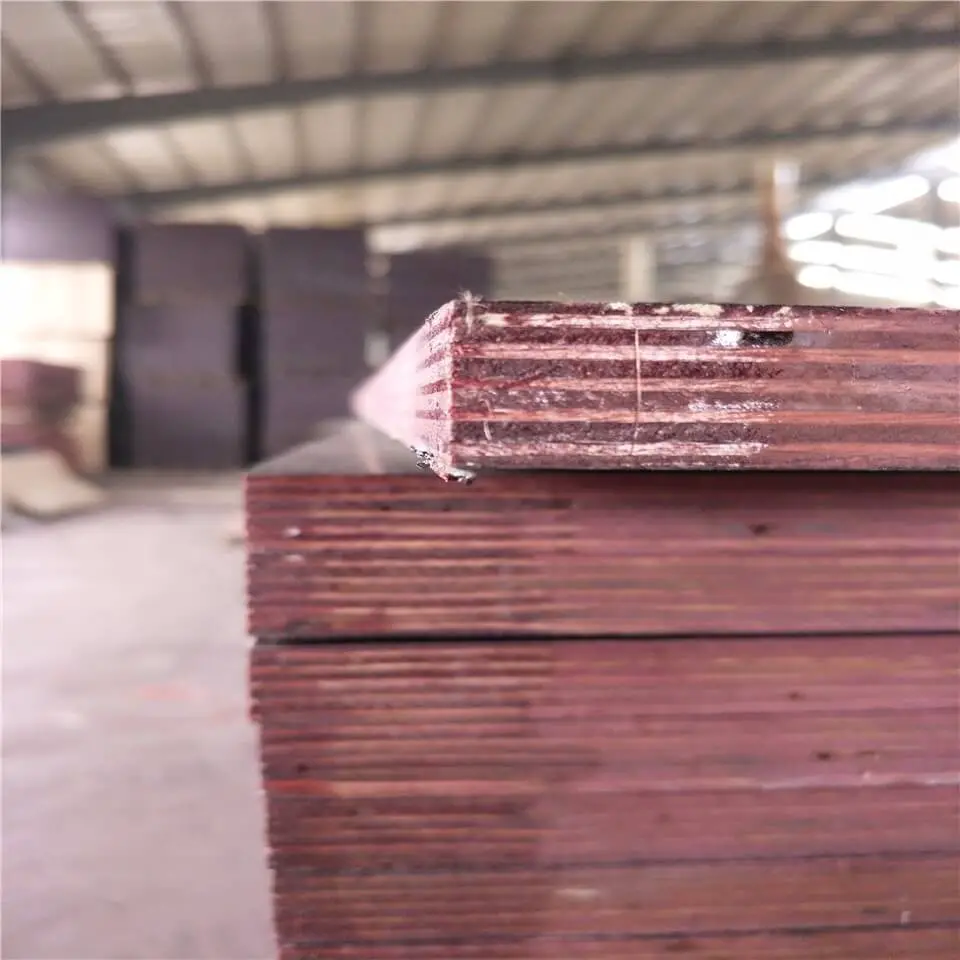

Tropical Plywood

While often referred to as the Asian equivalent of softwood plywood, Meranti plywood actually shares many similarities with its western counterpart. The primary distinction lies in its composition, which is derived from tropical timber sourced from countries like Indonesia, Malaysia, and the Philippines.

With a significant portion being exported to markets such as the UK and US, this type of plywood has garnered popularity due to its impressive characteristics, including a-grade density, consistent layering, and exceptional strength.

Flexible plywood

Flexible plywood is a versatile material that excels at bending and forming curves. Its unique composition makes it an ideal choice for constructing frame components with curved shapes and furniture pieces that require a high degree of flexibility. At its core, flexible plywood features a central ply with a cross-grained structure, which is sandwiched between two thicker plies with the same grain orientation.

To enhance its appearance, overlaid wood veneers are applied to the front surface, resulting in a smooth and lustrous finish. Interestingly, this type of plywood has a rich history, particularly in the UK, where it was once used to create stove-pipe hats during the Victorian era. Today, it is commonly referred to as ‘hatter’s ply’, a nod to its past applications.

Construction Plywood

The category of construction plywood encompasses a wide range of products, which can be broadly classified into structural and non-structural panels. This classification includes various types of panels such as particleboards, MDF core ply, foam boards, and others. While the non-structural boards may appear soft to the naked eye, it’s essential to note that all construction plywood products are remarkably sturdy.

Veneer core plywood

This type of plywood stands out for its unique construction, featuring an odd-numbered pattern of cross-grained veneers on its core. The central veneer is typically paired with alternating sides of veneers applied in a specific sequence, which creates a strong and durable material. Unlike traditional plywood, this variant boasts enhanced load-bearing capabilities, allowing it to support greater weights without compromising its structural integrity.

Additionally, the softness of this plywood makes it ideal for nail and screw holding, while its flexibility enables it to be bent into curved shapes with ease.

MDF core

Unlike particleboards, MDF core plywood stands out due to its unique composition of individual wood fibers. This distinct feature makes it a joy to work with, as it eliminates the messy production of wood chips or sawdust. Moreover, its flat surface is ideal for furniture bases and other applications where smoothness matters. Additionally, MDF core plywood is highly receptive to paints, resin, and vinyl coatings, making it an excellent choice for those who value aesthetics.

While it may be slightly heavier than other types of plywood, this drawback is largely outweighed by the material’s increased sturdiness and durability compared to particleboard.

ApplePly

Birch plywood stands out from its softwood and hardwood counterparts due to its unique layering structure, despite sharing similar grain patterns and color schemes. The construction process involves laminating strips of birch and alder wood, resulting in a robust yet lightweight wood board that has earned it a reputation as a premier choice for cabinetmaking and other wood furniture applications.

Moreover, this type of plywood is particularly user-friendly, as it resists tearing or fuzzing even when subjected to heavy-duty cutting machinery.

Exterior sheathing plywood

While there are numerous types of exterior sheathing plywood available, such as CDX, OSB (Oriented Strand Board) remains the most widely used. This re-engineered plywood boasts a remarkable two times greater strength than standard plywood, making it an ideal choice for applications like roofing, exterior sheathing, and roof decking.

When installed, OSB is typically bonded with waterproof adhesive to ensure a secure seal, often with a slight overlap (semi-exposure) to prevent wear and tear over time. Interestingly, its composition bears some resemblance to particle board, as both feature compressed wood flakes randomly arranged in various directions.

Subfloor plywood

At the core of any construction project lies a crucial component: the subfloor. This foundation is where the floor finish will be attached, making it essential to get it right. Among the various options available, two popular choices for subfloor plywood are OSB and CDX. Both offer superior strength compared to regular plywood, yet remain soft enough to accommodate nailing with ease.

Sundeala board

Plywood made from recycled newspapers is the most sustainable option, boasting a unique combination of eco-friendliness and durability. Measuring typically 4×8 feet, this versatile material is available in various color shades and is often used for cork boards or information boards, as well as in intricate modeling railways. Its reinforced construction ensures a sturdy final product that can withstand the test of time.

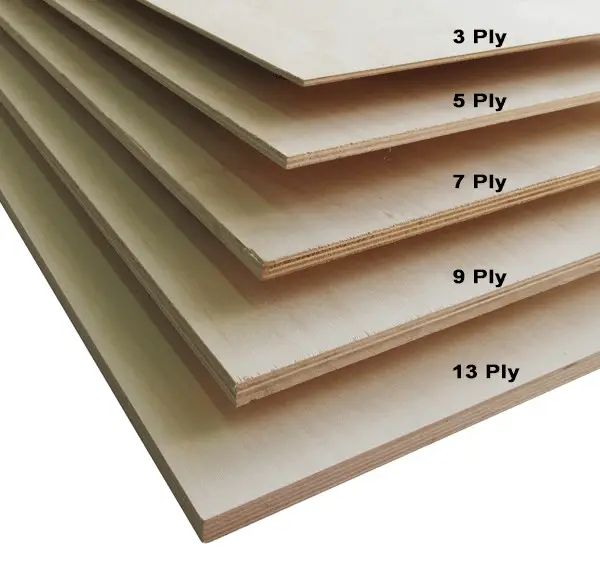

Types of Ply

The term ‘ply’ typically alludes to the varying levels of thickness found in various products, including wood. This accounts for why thicker plyboards exist alongside their thinner counterparts. Plyboard thickness is achieved by layering wood veneers on top of one another. With this foundation established, let’s proceed to explore the different types of ply.

3-Ply

This particular ply board consists of three layers of wood veneer, which makes it a widely recognized standard thickness. Its applications are generally focused on creating lighter woodwork pieces, often used indoors for projects like cabinets and drawers. While its primary purpose is decorative, this thickness still offers sufficient durability to meet the demands of various tasks.

5-Ply

Comprising five layers of wood veneers, this product is designed for moderate applications, unlike three-ply options which are typically used for heavier-duty projects. As a result, it’s well-suited for indoor woodworking endeavors that don’t necessitate exceptional wood strength.

Multi-Ply

Crafted from a minimum of eight wood veneers, this multi-ply board boasts exceptional durability and strength. Its robust nature makes it an ideal choice for exterior applications such as roofing, where weather resistance is crucial. Additionally, it finds widespread use in residential construction, serving as the foundation and frame for buildings, providing unparalleled structural integrity.

Plywood grades

Plywood quality is categorized into different grades, with each grade denoting the material’s strength, durability, and price. The most common grading system uses letters A to D, with A being the highest grade and D the lowest. However, this is not the only distinction, as many plywood types feature two-letter grades that indicate the quality of both the face (front) and back (core) of the board. The first letter represents the face grade, while the second letter represents the core grade.

This classification system helps determine which part of the board should be used for the face or backing. Generally, the lower-grade section is assigned as the backing.

When choosing a plywood grade, it’s essential to consider its intended use. For instance, A-C grades are suitable for exterior applications, such as building panels and woodworks, due to their durability and water resistance.

In contrast, C and D grades are more suitable for interior projects but should be properly coated or finished.

One additional factor to consider is the presence of an ‘X’ at the end of a grade. This indicates that the plywood has met certain strength tests, making it suitable for exterior applications. For high-end woodworks or demanding projects, A-B or CX grades are often preferred due to their absence of knotholes, providing a smooth surface for painting and staining.

Plywood sizes

Plywood dimensions encompass not only their thickness and length but also their specific purpose. The three most common sizes – 4x4ft, 4x8ft, and 4x9ft – each serve a distinct function. Thinner plywood is ideal for projects requiring flexibility, as it can be bent to create irregular shapes. Conversely, thicker plywood is designed to withstand harsh weather conditions and heavier loads.

One notable characteristic of plywood is its length, which can often be trimmed down to precise sizes upon request from the lumber supplier. This is crucial, as the listed size may not accurately reflect the actual dimensions. For instance, a ¾ inch plywood might have a 1/32 inch discrepancy due to variations in measurement. Furthermore, it’s essential to note the unit of measurement used by the supplier – while inches are standard, some still use millimeters.

When selecting plywood, consider these factors to ensure the right fit for your project.

Plywood price

When it comes to pricing, the type of plywood grade plays a significant role. In this section, we’ll provide an estimate of the cost for construction-grade and cabinet-grade plywood. Construction-grade plywood includes OSB and CDX ply options. A 4×8 sheet of CDX ply with a thickness of 15/32” typically costs between $28-30, while a thicker 23/32” option ranges from $35-37. In contrast, OSB ply pricing varies depending on the thickness, ranging from $5-15.

For cabinet-grade plywood, sanded pine ply is priced between $13-21, while hardwood ply options range from $18-45. Oak hardwood ply tends to fall within the $25-45 bracket, and birch plywood typically costs between $41-45.

What is Plywood used for?

Plywood’s versatility makes it an ideal material for a wide range of woodworking projects. Its flexibility allows for reinforcement or decorative finishes, making it suitable for both interior and exterior applications. Frames, building foundations, sheaths, paneling, and other construction-related work can all benefit from its durable and sturdy composition.

Furthermore, the affordability of plywood makes it a popular choice for shelving, furniture-making, casings, and various other types of woodwork projects.

How do I choose plywood?

When selecting the ideal plywood for your project, several key factors should be taken into account. To ensure you find the perfect plywood for the task at hand, consider the following essential elements: the type of plywood, its flatness, edge quality, size and thickness, as well as the grade. By carefully evaluating these characteristics, you’ll be better equipped to make an informed decision and choose a high-quality plywood that meets your specific needs.

Type of plywood

When it comes to selecting the ideal plywood for your project, understanding its specific characteristics is crucial. Different types of plywood possess unique strengths, making some more suitable than others for particular tasks. By choosing the right type from the start, you can avoid costly mistakes and potential future repairs. Exterior projects, such as decking or fencing, typically benefit from lumber core, aircraft, hardwood, softwood, marine, or structural plywood.

In contrast, sheathing and roofing applications often require OSB or CDX plywood. For interior projects like cabinets and woodwork, consider using softwood, marine, tropical, or flexible plywood.

Flatness

When selecting plywood, its flatness should be a key factor in your decision-making process. A general guideline is that the flatter the plywood, the more manageable it will be during installation. While some commercial suppliers may still offer bowed plywood, keep in mind that such products can prove challenging to work with, especially when tackling large-scale projects like door installations or roof decks.

Additionally, if a sheet of plywood falls short of the 80-95% flat standard, it’s likely due to issues with its gluing process.

Edges

When it comes to evaluating the quality of a plywood product, one crucial aspect is often overlooked: the thickness of the veneer edges. This measurement can be taken by examining the edges of the plywood itself. A general guideline suggests that thicker veneer edges equate to higher-quality plywood. Conversely, thinner veneered plywood may pose difficulties during the sanding and finishing processes.

Furthermore, if gaps or knots are already apparent on the edges, it’s likely that these imperfections will be more pronounced throughout the entire sheet.

Size

While the thickness of a plywood may seem like a straightforward consideration, it’s crucial to remember that larger doesn’t always mean better. The standard 4×8 size is indeed popular, but it’s essential to consult with your contractor or assess the specific requirements of your project before making a decision. Notably, the size of the plyboard can have a direct impact on its durability and strength.

For instance, projects that involve frequent nailing or screwing may not benefit from overly robust plyboards, which could be too rigid for the task at hand.

Plywood grade

While it’s true that higher-grade plywood tends to be finer and smoother, it’s not always necessary to opt for the highest quality. In fact, for certain applications like subflooring, grades C or D can be a suitable alternative. However, when it comes to projects that require durability and resistance to the elements, such as decking, roofing, and exterior construction, A-grade plywood is usually the best choice.

Brand

When venturing into the world of plywood for the first time, having a basic understanding of leading brands can be a significant advantage. This is particularly true for novice shoppers who may not be familiar with the various types and grades of plywood available. A quick scan of well-known manufacturers’ product offerings can help you get a sense of the market prices and make informed purchasing decisions.

Reputable brands typically carry a wide range of plywood products, including their respective variants and grades. If you have a trusted local lumber supplier in mind, you can rest assured that they will likely have an extensive selection to meet your needs.

FAQs

While we’ve covered the fundamentals of plywood types and choosing the right one for your woodworking project, there’s still more to explore. To provide a comprehensive guide, we’ll also tackle the most commonly asked questions related to plywood types, addressing all the essential queries in this section.

What is the strongest type of plywood?

While marine plywood may not be as well-known as some other types of plywood, its impressive strength and durability make it the top choice for many construction and renovation projects. Through a rigorous process that involves pressing, heating, and polishing, marine plywood is treated to withstand exposure to moisture and extreme temperatures. This treatment also makes it resistant to cracking, twisting, and warping – giving it an A-A grade rating.

As a result, this exceptionally tough plywood is often used for both exterior and interior applications where water resistance is crucial, including subflooring, roof decks, and basements.

What types of plywood is waterproof?

When searching for plywood that can withstand moisture or rainwater, consider CDX, pressure-treated options like construction and structural plywood, marine-grade plywood, and OSB plywood. Before selecting a type, it’s essential to know its waterproofing capabilities. One way to determine this is by conducting a simple test. However, we’ll be exploring DIY methods for waterproofing plywood in a future article.

What is the cheapest type of plywood?

When it comes to plywood grades, C and D grade options are typically the most budget-friendly choices. This is because they feature visible knots and veneers with less rigorous repair, resulting in noticeable gaps. Despite this, they still offer satisfactory durability and sturdiness. In fact, CDX plywood is a prime example of an affordable option that’s both rugged enough for exterior work and suitable for interior projects.

Moving on to types, construction-grade materials like particle boards and foam boards are often the most economical options.

What is the best plywood for kitchen cabinets?

When it comes to choosing the ideal plywood for your kitchen cabinets, whether you’re opting for hanging or base models, high-grade marine plywood stands out as the top contender. The kitchen is notorious for its humid environment, which can lead to mold growth, mildew, and even rot. To combat these issues, a moisture-resistant material like marine-grade plywood is essential. Its inherent properties make it an excellent choice for kitchen cabinets, ensuring durability and longevity.

While hardwood and softwood plywood are respectable alternatives, marine-grade plywood remains the gold standard in this regard.

Which plywood is good for interiors?

Plywood has been a staple material in interior design for years, particularly when it comes to crafting cabinets and shelves. Among the various types of plywood, certain grades stand out as ideal for interior fixtures. MR grade plywood, also known as moisture-resistant ply, is a popular choice for living rooms and kitchens. While it’s not suitable for bathroom use due to its limited resistance to moisture, it excels in areas where humidity levels are relatively low.

In contrast, BR grade plywood – often referred to as marine ply – boasts even greater moisture-resistance, making it an excellent option for kitchens and bathrooms. For building interior fixtures like cabinets, home decor items, or lightweight furniture, particleboard and MDF (medium density fiber) are viable alternatives, although they lack the same level of moisture-resistance as MR or BR grade plywood. Other options to consider include tropical plywood and overlaid plywood.

What is the best plywood for outdoor use?

When it comes to using plywood outdoors, such as on a roof or deck, you’ll want to opt for types that can withstand the elements. In this case, the top contenders include hardwood plywood, structural plywood, exterior-grade plywood, ACX grade plywood, and marine-grade plywood – all of which are designed to perform well in harsh weather conditions.

What is the best marine plywood?

When it comes to selecting the right marine plywood for your project, durability is paramount. Fortunately, marine plywood is specifically engineered to withstand extreme conditions, and its construction is rooted in the use of Western larch or Douglas fir woods. What sets marine plywood apart from other types is its exceptional fineness – a notable feature that eliminates knotholes altogether.

At the top of the hierarchy lies A-A to A-B grade marine plywood, widely regarded as the gold standard for marine applications. If you can’t quite stretch to this premium option, high-density overlay marine ply provides an excellent alternative.

Is MDF stronger than plywood?

While plywood is a popular choice for many woodworking projects, medium-density fiberboard (MDF) offers a distinct set of benefits that elevate it to a higher level. In fact, MDF shares similarities with solid wood or hardwood in terms of its strength, density, and durability. As an engineered wood product, MDF is well-suited for demanding applications such as heavy-duty cabinets and shelves, as well as exterior use cases where it can withstand the elements.

Its design also allows for efficient processing through machines via drilling, cutting, and other methods. In contrast, plywood is often preferred for projects like building staircases, doors, exterior fixtures, and subflooring, where its natural resistance to warping and its ability to absorb shock are valuable assets.

Is OSB as good as plywood?

While often referred to as OSB plywood due to its similar composition – smaller pieces of wood glued together – oriented strand board (OSB) has some notable advantages over traditional plywood. In fact, when it comes to sheer strength, OSB outperforms plywood by a significant margin, boasting a 2:1 advantage.

This enhanced durability makes OSB an attractive alternative for exterior applications such as roof decks and sheathing, where its increased thickness and length also provide added benefits.

Conclusion

Plywood has gained popularity over the years due to its numerous advantages. Not only is it an affordable option, but its versatility also makes it suitable for various tasks. The different types of plywood cater to specific needs, offering a more budget-friendly choice for particular projects. While it may not possess the same luxurious appeal as solid wood, plywood’s low-maintenance quality and moisture-resistant characteristics make it a reliable choice.

Moreover, certain types of plywood exhibit exceptional warp-resistance, twist-resistance, and bend-resistance – features that are absent in solid wood. This versatility enables you to construct a wide range of projects, whether exterior or interior, with the assurance of durability. While choosing the best plywood for your needs requires some consideration, these basic pointers can be quickly mastered.

Related Posts

While pellet stoves can be an efficient and environmentally friendly way to heat a home, they may not be suitable for heating an entire house. However, with the right design and installation, it is possible to heat a significant portion of a larger dwelling. The key is to determine how many square feet of living space can be effectively heated by a pellet stove, as well as considering factors such as insulation, window placement, and overall building structure.

By understanding these variables, homeowners can make an informed decision about whether a pellet stove is the right choice for their unique situation.