What Are Ceramic Molds Used For?

Ceramic molds are a type of mold used for casting processes, primarily metal casting. They are made from ceramic materials such as clay. Ceramic molds are created by first shaping the desired final product out of wax, wood, plastic, or another material. This shape is known as the pattern. Molten ceramic is then poured over the pattern and allowed to harden, creating the mold.

Once the ceramic mold hardens, the pattern is removed, leaving behind a hollow mold. This mold can then be filled with molten metal, wax, plastic, or other pourable material to create castings. The most common use of ceramic molds is for metal casting, however they can also be used for jewelry making, candle making, chocolate and sugar work, and other applications.

Ceramic molds have several key advantages over other mold types like sand molds. They can achieve extremely smooth surface finishes on castings. They also hold their shape well through multiple uses. Their porous nature allows gases to escape during the casting process. Overall, ceramic molds enable very high accuracy and repeatability.

According to Wikipedia, the main uses for ceramic molds are “casting steels and most non-ferrous metals and alloys, casting reactive metals such as titanium and zirconium, casting metal matrix composites, die-casting, investment casting, and other specialized casting methods.”

Casting Ceramic Objects

Ceramic molds are commonly used to cast ceramic objects like pots, dishes, sculptures, and other decorative pieces. The process involves pouring slip, which is liquefied clay, into a plaster mold. As the slip touches the mold, it starts to solidify from the outside in, forming a hollow ceramic object.

This casting technique allows the creation of intricate shapes and patterns not easily made by hand. Once the slip dries fully in the mold, the newly cast ceramic piece can be removed and cleaned up. The porous plaster absorbs water from the slip, causing it to solidify.

Ceramic mold casting has been used for thousands of years to mass produce ceramic objects with consistent shapes and decorative designs. It allows faster production compared to throwing pots completely by hand. Archaeological evidence shows the ancient Greeks used plaster molds to produce oil lamps, bowls, and figurines as early as the 5th century BC.

Today, ceramic artists and industrial manufacturers continue to use plaster molds to replicate designs and standardize production. The technique is ideal for complex forms like teapots with spouts and handles that would be difficult to throw on a wheel.

Some cons of ceramic mold casting include less flexibility compared to handmade pieces and slight variations between casts. But it remains an essential technique for efficient and affordable ceramic production.

Sources:

https://en.wikipedia.org/wiki/Ceramic_mold_casting

https://www.xometry.com/resources/casting/ceramic-mold-casting/

Metal Casting

Metal casting using ceramic molds is a common manufacturing technique that allows for precise, repeatable production of metal parts and objects. Ceramic molds are often used for metal casting because ceramics can withstand extremely high temperatures needed for melting and pouring molten metal (Xometry, 2022).

The process starts with creating a ceramic mold, usually made of silica. The mold is formed by packing silica sand around a pattern, then compacting it and firing it to harden the mold. Molten metal is then poured into the mold cavity, where it cools and solidifies into the desired shape. Once cooled, the mold is broken away, leaving the cast metal part (Wikipedia, 2022).

Compared to sand casting, ceramic mold casting produces metal parts with tighter dimensional accuracy, smoother surfaces, and finer details. Intricate shapes and patterns can be molded. Ceramic molds also have higher durability for longer production runs. Common applications include automotive parts, valves, pumps, and jewelry casting.

Overall, ceramic molds allow for precise, repeatable metal casting for manufacturing functional metal components and products. The ceramic mold’s heat resistance and durability make it well-suited for casting complex, detailed metal parts.

Jewelry Making

Ceramic molds are commonly used to cast jewelry pieces like rings, pendants, beads, and more. The process involves pouring a liquid casting material like wax or metal into the mold cavity. Once hardened, the cast piece can be removed and finished.

Jewelry molds are available in many shapes like circles, ovals, hearts, etc. to cast various jewelry components. According to Glaser Ceramics, their heart pendant glass mold can cast four 1.5 x 1.75 inch heart pendants at a time. The molded pieces can then be turned into necklaces or other jewelry.

Ceramic bead molds are also popular for handmade jewelry making. As Etsy shows, there are many bead shape options like rounds, cubes, tubes, and more. Jewelers simply pour colored liquid polymer clay or other casting material into the mold, let it cure, and then string the beads together to form necklaces, bracelets, and other jewelry.

Overall, ceramic molds allow jewelers to easily replicate jewelry components in various designs. The ability to repeatedly cast intricate pieces in wax or metal is invaluable for scaled jewelry production.

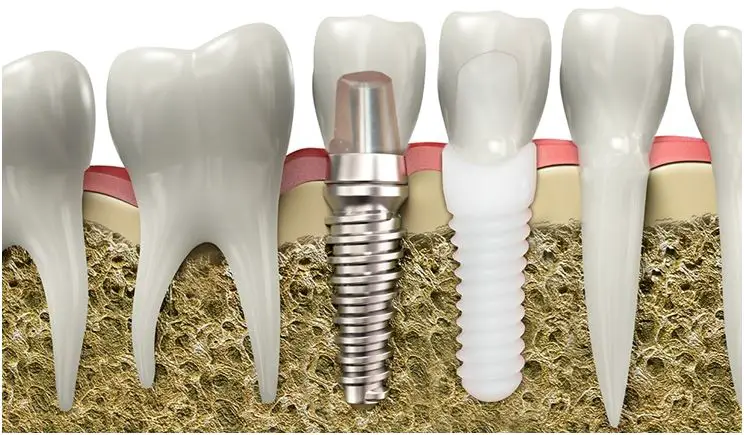

Dental Applications

Ceramic molds are commonly used in dentistry to create custom dental implants, dentures, crowns, and other dental prosthetics. The molds are made from high-strength ceramic materials that can withstand the high temperatures needed to cure dental ceramics.

To create a custom dental prosthetic, an impression is first taken of the patient’s mouth using dental alginate or silicone. This impression is filled with dental stone or plaster to create a negative mold of the patient’s teeth and gum tissue.

The dental technician then sculpts a positive wax model of the prosthetic based on the stone mold. This wax model is placed into a ceramic mold filled with investment material. The investment material sets around the wax model to create a hardened shell.

The ceramic mold is then heated, burning out the wax and leaving a hollow cavity in the shape of the prosthetic. Dental ceramic powder is packed into this cavity and fired at high temperatures to produce the final ceramic restoration.

Some common ceramic materials used for these molds include zirconia, alumina, lithium disilicate, and feldspathic porcelain. The high heat resistance and precision of ceramic makes it possible to fabricate highly accurate and durable dental prosthetics.

Sources:

https://usdentaldepot.com/laboratory-supplies/waxes-all-types/molds-for-wax-patterns/mold-4-full-porcelain-coverage-taub/ceramic-mold/

https://www.etsy.com/market/dental_plaster_mold

Candle Making

Ceramic molds are commonly used in candle making to create decorative and artistic candle designs. The rigid structure of ceramic allows candle makers to mold candles into various shapes like jars, votives, pillars, and unique sculptural forms.

Ceramic offers excellent mold release properties, allowing candles to be easily removed once cooled and hardened. Glazing the interior of ceramic molds creates a smooth surface finish on molded candles.

Ceramic candle molds are valued for their durability, allowing them to be reused repeatedly for production candle making. High firing temperatures make ceramic molds resistant to warping from exposure to hot wax. Popular ceramic candle mold designs include geometric shapes, floral motifs, novelty figures, and holiday themes.

Custom ceramic molds can also be created to produce branded or personalized candle designs. Ceramic’s heat resistance allows it to withstand wax temperatures up to 185°F during the candle making process.

Sources:

https://boowannicole.com/collections/candle-jar-mold

https://madmolds.com/collections/candle-candlestick-holder-molds

Concrete Casting

Ceramic molds are commonly used to cast decorative concrete objects like countertops, furniture, and architectural details. The cement is poured into the mold while wet and allowed to cure and harden, taking on the shape of the mold. Ceramic is ideal for concrete casting because it is durable, heat resistant, and provides a smooth finish.

Ceramic casting molds for concrete are available in many shapes and sizes, from simple geometric shapes to intricate decorative designs. The molds have openings that allow the wet concrete to be poured in. Some molds are designed in multiple pieces so they can be unmolded once the concrete has set up. The smooth ceramic surface results in a smooth finish on the cast concrete object.

Large molds are used to cast concrete countertops, sinks, bathtubs, and other large items. More detailed molds are used for smaller products like decorative moldings, column capitals, furniture legs, and architectural accents. Using a ceramic mold allows limitless shapes and designs to be molded from concrete.

Ceramic molds must be sealed before casting concrete to prevent adhesion and allow for easy release. Release agents like petroleum jelly or liquid wax are applied to the mold surface. The ability to reuse ceramic molds repeatedly makes them a cost-effective option for concrete casting. Proper care and storage of the molds is required for longevity and quality results.

Chocolate and Sugar Work

Ceramic molds are commonly used in chocolate and sugar work for shaping and molding candies, chocolate, sugar, and other edible mediums. Ceramic candy molds allow chocolatiers and confectioners to create detailed and intricate designs and patterns for their creations. The rigid structure of ceramic allows for more defined edges and shapes compared to more flexible materials like silicone.

Ceramic candy molds are available in a wide variety of themes and designs, from geometric shapes to flowers and animals. Custom ceramic candy molds can also be specially ordered for unique designs. Chocolatiers often use multiple piece ceramic molds to create hollow chocolate shells or filled chocolate candies. These molds lock together to create the inner cavity before being filled with chocolate or candy and cooled until set.

For baking, ceramic cake molds and pans provide an attractive way to shape cakes and baked goods. The ceramic evenly distributes heat for even baking and cooling. Ceramic baking molds come in many shapes like hearts, stars, and detailed character molds. The rigid ceramic holds its shape well compared to metal pans. (Source)

Soap Making

Ceramic molds are commonly used in handmade soap making. The porous nature of ceramic allows air bubbles to escape through the mold as the soap hardens, resulting in a smooth finish. Ceramic holds up well to the caustic nature of soap and can withstand the heat from hot processed soaps. It provides a nonstick surface that allows the hardened soap to be removed from the mold easily. Ceramic molds come in a wide variety of shapes and sizes to create decorative soaps.

According to The Ceramic Shop, ceramic soap molds are ideal for melt and pour, cold processed, and hot processed soaping techniques. They offer a large selection of creative soap molds like loafs, bars, guest soaps, embeds, and more. Ceramic withstands years of repeated use without absorbing fragrance oils.

MoldMarket specializes in ceramic craft molds for soap making. They have unique designs like rope baskets, sand dollars, sea shells, and more. Their molds hold intricate detail for creating decorative soaps. MoldMarket recommends only using their molds for cold processed and hot processed soap, not melt and pour.

Conclusion

Ceramic molds have a wide variety of important uses across many industries and applications. From casting intricate metal parts and jewelry to forming candles and chocolates, ceramic molds enable the efficient mass production of detailed objects. Their heat resistance and durability allow ceramics like plaster and silica to be reused many times in high temperature environments.

The ability to craft precision molds which can withstand molten metals and hold fine details makes ceramic molds invaluable for manufacturing and creative pursuits. Whether an engineer needs to fabricate a new mechanical component or a confectioner wants to make elaborate edible decorations, ceramic molds are an essential tool. Their non-porous nature provides smooth finished surfaces and allows for easy release of contents.

In summary, ceramic molds are a versatile production method that drives innovation across multiple fields. From dentistry to decoration, their unique properties enable the creation of precise items out of materials that would otherwise be impossible to form. Ceramic’s strength, longevity and heat tolerance will ensure these molds continue finding new applications well into the future.