What Are Fibre Clay Pots Made Of?

What is Clay?

Clay is a type of fine-grained natural soil material that is plastic when wet and hard when fired, making it an ideal medium for pottery and ceramics. There are several types of clay used for making pottery, including:

Earthenware clay – A lower-fired clay that is porous and reddish-brown in color after firing. Earthenware clays are easier to work with and more accessible.

Stoneware clay – A higher-fired clay that vitrifies and becomes nonporous and watertight after firing. Stoneware clays can withstand thermal shock.

Porcelain – A fine white clay that fires to a smooth, glassy finish. Porcelain is highly impermeable and durable.

The properties that make clay good for pottery include its plasticity when wet, ability to harden when fired, small particle size, and low solubility. Clays are moldable in their wet state, allowing potters to shape and decorate pieces. When fired, the clay undergoes permanent physical and chemical changes, making the final product durable and water-resistant.

History of Clay Pottery

The history of clay pottery dates back over 20,000 years. Archaeologists have uncovered primitive clay figurines and vessels at sites in Czechoslovakia dating between 24,000-27,000 BC. As early humans transitioned from nomadic hunter-gatherers to settling in permanent locations, clay pottery became an important tool for storing food and water.

Pottery artifacts have been found amongst the ruins of ancient Mesopotamian, Egyptian, Greek, Roman, Chinese and Aztec civilizations. Cooking pots, storage vessels, plates, cups and figurines were all fashioned by hand from clay soils, hardened in open fires or rudimentary kilns. Traditional techniques like coiling, pinching and scraping were used to shape the clay, while decorations were painted or etched onto the surface.

Over thousands of years, clay pottery evolved with advancements in glazing techniques and kiln technology. Unique regional styles also emerged across the ancient world, from the black and red figure pottery of the Greeks to the green glazed ceramics of the Islamic empires. However, the basic methods of hand-forming and decorating clay vessels remained unchanged until industrialization brought about mechanized production.

Making Fiber Clay

Fiber clay is a type of pottery clay that contains natural fibers mixed into the clay body. The addition of fibers provides strength and durability to fired clay pieces. The most common fibers used in fiber clay are paper, hemp, cotton, and wool.

Paper fiber clay contains recycled paper pulp. The paper fibers bond with the clay particles during firing to reinforce the clay matrix. Paper fiber clay has a coarse texture and requires extra care when handling in its unfired state. It can crack more easily than smooth clays. The coarseness provides an interesting visual texture in finished pieces. Recycled paper pulp helps utilize waste materials.

Hemp fiber adds toughness and strength to clay pieces. Hemp has long fibers that mesh well with clay particles. The natural fibers prevent cracking, shrinking, and warping during drying and firing. Hemp fiber clay fires to a light brown or buff color. The hemp gives pottery an earthy, organic look and feel.

Cotton fibers create a soft, flexible clay for handbuilding pottery and sculpture. Cotton fiber clay is very strong when fired but remains lightweight. The cotton burns out during firing, leaving small cavities that reduce the density. This makes cotton clay ideal for large pots and decorative wallhangings. The fired surface takes paints and glazes well.

Wool fiber clay provides elasticity for stretching and coiling clay forms. Wool integrates into the clay matrix while retaining enough flexibility to resist cracking and tearing when worked by hand. Wool fiber clay can be fired at relatively low temperatures. The wool burns out completely during firing, so the finished ceramics are lightweight.

Benefits of Fiber Clay Pots

Fiber clay pots have several advantages over traditional clay pots. The addition of natural fibers like hemp, jute, or sisal makes the clay mixture more durable and less prone to cracking. The fibers act as a reinforcing agent in the clay body.

The porous nature of the natural fibers increases the breathability and moisture control of fiber clay pots. This is especially useful for planting containers, allowing air circulation to the roots while also absorbing excess water. The improved breathability helps prevent root rot.

With traditional clay, pots can easily crack during the drying and firing process due to shrinkage and thermal shock. The fibers in fiber clay pots make the clay mixture more flexible and resistant to cracking. Even when fired to higher temperatures, fiber clay pots retain their structural integrity better than regular clay.

Additionally, fiber clay is less likely to crack or break when dropped. The fibers disperse shock throughout the material, preventing cracks from propagating through the clay body. This makes fiber clay pots more durable and resilient for everyday use.

Fiber clay’s increased durability and porosity make it an excellent choice for crafting sturdy yet breathable planting containers. The natural fiber reinforcement results in pots that withstand weather fluctuations and last longer than traditional clay vessels.

Making Fiber Clay Pots

Making fiber clay pots begins with preparing the clay mixture. The clay is mixed with natural fibers like hemp, jute, or sisal to increase its durability and strength. The ratio of clay to fiber is usually around 50/50 but can be adjusted based on the desired properties and thickness of the finished pot.

Fiber clay pots can be made either on a pottery wheel or by handbuilding techniques. On the wheel, the process is similar to regular clay but the fiber mix makes the clay stiffer and requires more water to keep it workable. For handbuilding, the clay can be rolled out into slabs, coils or used to sculpt shapes. The added fibers help the clay hold its form better than regular clay.

Once shaped, the pots are left to air dry thoroughly before firing. Fiber clay pots must be fired slowly to allow the fibers to burn out without cracking the clay. Typical firing temperatures are 1800-2000°F. The fibers burn away completely during firing, leaving micropores in the clay that make the finished pots lightweight and breathable. The end result is a durable, sturdy pottery perfect for daily use.

Decorating Fiber Clay Pots

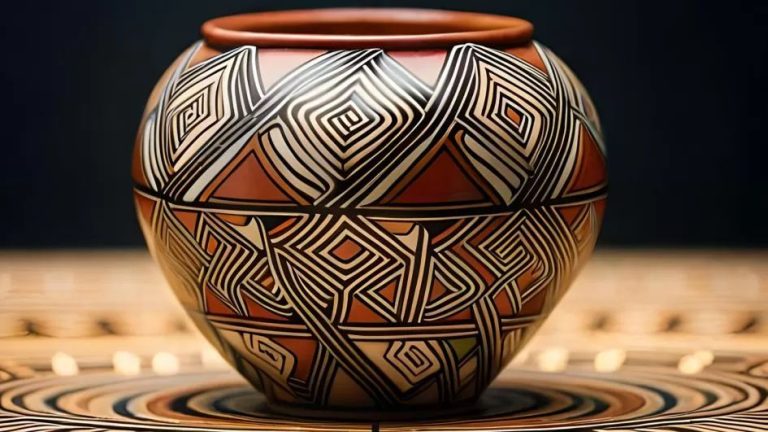

Fiber clay pots can be decorated in various ways to give them a unique and artistic flair. Some popular decoration techniques include glazing, coloring, texturing, and adding embellishments.

Glazing and Coloring

Glazes come in many colors and finishes to give fiber clay pots an extra dimension. Similar to ceramic glazes, fiber clay glazes melt during firing to create a glossy coated surface. Acrylic paints can also be used to hand-paint designs onto bisque fired pots. Other colorants like mason stains, underglazes, and pigments can be mixed into the clay body itself to achieve an integrated color effect.

Texturing

Fiber clay can be textured in multiple ways while still soft, or imprinted with texture sheets, rubber stamps, or found objects before firing. Popular texturing techniques include paddling, scraping, rolling, carving, embossing, and indenting the surface. This adds visual interest and a tactile quality to the final pot.

Adding Embellishments

Fiber clay pots can be further adorned with additional decorative elements like beads, buttons, seashells, stones, glass bits, or foliage. These can be pressed into the soft clay before firing, or glued onto the finished piece afterwards. Embellishments add personality and one-of-a-kind charm to fiber clay pottery.

Using Fiber Clay Pots

Fiber clay pots are known for their durability and versatility, making them ideal for a wide range of uses. Here are some of the best ways to utilize these attractive yet functional pots:

Planting Containers

One of the most popular uses for fiber clay pots is as planting containers for flowers, herbs, vegetables, and other plants. The porous material allows for air circulation to the roots while also providing drainage. Fiber clay pots come in a huge variety of shapes and sizes, allowing you to pick the perfect pot for each plant.

Proper Drainage

Ensuring proper drainage is key when using fiber clay pots. The material naturally allows water to flow through it, but you can further improve drainage by putting pebbles or small rocks at the bottom of the pot below the soil. This creates air pockets for excess water to drain away from the roots. You can also choose pots with multiple holes in the base.

Care and Maintenance

Fiber clay is durable, but pots still require some care. Avoid leaving them outside in freezing weather, which can cause cracking. Check pots occasionally for any cracks forming and repot plants if needed. Fiber clay’s porous surface can also stain over time. Gently clean with mild soap and water when needed to keep pots looking their best. With proper care, fiber clay pots can last for many seasons.

Notable Fiber Clay Artists

Fiber clay pottery has been elevated to an art form by talented artists around the world. Here are some of the most influential fiber clay artisans to know:

Akiko Hirai

Based in Japan, Akiko Hirai is known for her nature-inspired fiber clay pots embellished with intricate pressed flower and leaf designs. She hand-presses each botanical detail into the surface before firing. Hirai’s work has been exhibited internationally and can be found in museum shops and high-end galleries.

Fatmir Mura

Albanian ceramicist Fatmir Mura specializes in Minimalist fiber clay vases, bottles, and bowls. His creations feature smooth matte finishes and geometric shapes in neutral tones. Mura’s work combines modern aesthetics with ancient pottery techniques. His pieces are available via major online retailers.

Tyler Hays

Los Angeles artist Tyler Hays founded Babel Studio, dedicated to experimental fiber clay sculpture and pottery with influences ranging from Antoni Gaudi to Jean-Michel Basquiat. Hays’ pieces push the boundaries of traditional vessels with bold shapes, colors, and mixed media accents. Babel Studio works are shown in galleries worldwide.

Accessibility of Fiber Clay Pots

Fiber clay pots have become more accessible and affordable in recent years. Here are some options for obtaining fiber clay pots:

Online Stores

Many online retailers sell finished fiber clay pots in various shapes and sizes. Sites like Etsy have thousands of handmade fiber clay pots for sale from independent artists and small businesses. Amazon and large craft retailers also carry fiber clay pottery. Online stores offer convenience and variety when shopping for high-quality, unique fiber clay pots.

Local Craft Stores

Major craft stores like Michaels often stock fiber clay alongside regular pottery clay. Check the polymer clay or pottery section. Local arts and crafts stores are another option for purchasing blank fiber clay ready for crafting. These provide the opportunity to see products in person.

Make Your Own

For total control over the clay texture and colors, many crafters choose to make their own fiber clay. The process is inexpensive, utilizing natural ingredients like clay, paper, cornstarch, and glue. Homemade fiber clay allows customizing pots to match your decor. And it can be a fun project for crafty hobbyists.

Affordable Prices

Both purchased and homemade fiber clay pots are relatively affordable. Premade small pots cost just a few dollars each. Blank clay ranges from $10-20 per pound. With numerous budget-friendly options, beautiful fiber clay pottery can fit most any price point and budget. The handcrafted look provides great value for the cost.

Future of Fiber Clay Pottery

Fiber clay pottery has a long and storied history, but its future looks just as bright. While the fundamental techniques and artistry remain rooted in tradition, fiber clay artists continue finding new ways to innovate and evolve their craft.

Advancements in materials science allow for the development of new clay compositions with enhanced properties. The incorporation of alternative fibers like nylon and carbon fiber opens up new realms of possibility. 3D printing technologies enable faster prototyping and more intricate designs. Lasers provide precision cutting and etching capabilities to supplement hand carving techniques.

As fiber clay gains popularity in art circles, creators are pushing the boundaries and exploring new applications. Sculptors take advantage of the lightweight nature and flexibility to craft large-scale installations. Product designers use it to make household goods like vases, lamps, and tableware. Architects integrate custom fiber clay tiles or accents into buildings. The unique characteristics make fiber clay well-suited for a wide range of creative uses.

While remaining anchored in centuries of tradition, the future of fiber clay pottery shines bright with possibility. Master artisans pass down knowledge to new generations, CARRYING ON rich cultural heritage while embracing new technologies and innovations. The synergy of old and new will propel fiber clay into an exciting future of continued evolution and wider recognition.