What Does Ftl Mean On A Paragon Kiln?

FTL stands for “Firing Too Long” and is an error code that can appear on Paragon kilns equipped with the Sentry 12-key controller during the firing process. Paragon kilns are electric kilns used by ceramic artists, potters, hobbyists, and commercial ceramic manufacturers for firing clay work. The FTL error indicates the kiln has exceeded the maximum firing time programmed into the controller, stopping the firing for safety reasons. On Paragon kilns, FTL protects against potentially dangerous runaway kiln firings by automatically shutting the kiln off when the firing cycle surpasses the expected time frame.

What Does FTL Stand For?

FTL stands for “Fire to Lose”, which is a temperature rating used on some kilns, primarily Paragon kilns. It refers to the highest temperature the kiln can reach in the “Fire to Lose” range, which is typically around 2350°F (1288°C).

The FTL acronym originated with Paragon kilns as a way to designate the maximum temperature for firing their kilns without damaging the elements. FTL firing is meant for high temperature glaze firings, glass fusing, and other applications that require reaching temperatures between 2000-2350°F. The FTL rating helps kiln owners understand the kiln’s safe operating limits.

So in summary, FTL is a Paragon-specific term indicating the upper temperature limit that a kiln can reach in the “Fire to Lose” range before risking element failure. It provides useful guidance on how hot that particular kiln model can safely fire.

FTL on Paragon Kilns

FTL stands for “Fired Too Long” and is a feature specific to Paragon kilns. It is a safety mechanism that monitors the rate of temperature increase during the firing process. If the temperature does not increase quickly enough, the FTL feature will be triggered and the firing will be stopped.

On Paragon kilns, the FTL feature is designed to shut down the firing if the temperature does not increase by at least 60°C/108°F per hour. The kiln’s control panel monitors the rate of temperature rise throughout the firing. If it detects the rate has slowed to less than 27°C/60°F per hour for a period of 4 minutes, the FTL alarm will sound and the firing will be halted.

The FTL feature helps prevent damage to kiln elements and fired ware. A slowed temperature increase often indicates a problem with the kiln, such as failing elements or a Temperature Control Module issue. The FTL system shuts down the firing before these problems can cause the kiln to overfire the ware inside.

On Paragon kilns, the FTL feature cannot be disabled. It functions as an automatic safety precaution whenever the kiln is fired. If FTL is triggered, the kiln control will display an error code, indicating the firing was stopped due to insufficient temperature increase.

FTL Temperature Range

FTL stands for “Firebrick Temperature Limit” and corresponds to a temperature range of 1850°F to 2372°F (1010°C to 1300°C). This temperature scale was created by kiln manufacturers to measure the maximum safe operating temperatures for kilns lined with firebrick refractory material.

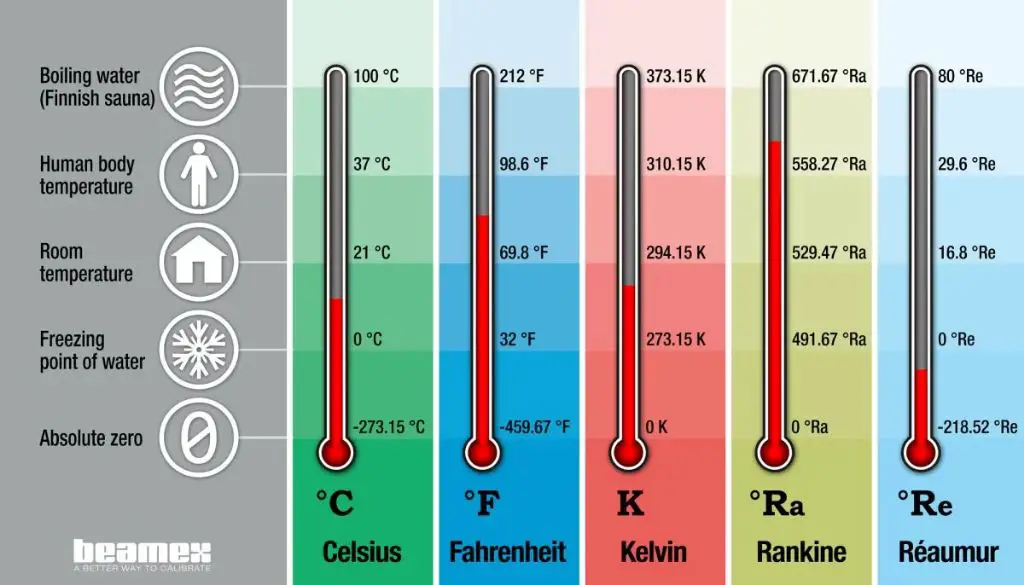

Compared to other common temperature scales, FTL is a relatively high temperature range. For reference, some comparable temperature equivalents are:

- 1850°F FTL = Cone 010

- 2012°F FTL = Cone 6

- 2282°F FTL = Cone 10

- 2372°F FTL = Cone 12

So FTL corresponds to approximately cone 010 to cone 12 on the Orton pyrocones scale. It is a higher range than for Celsius or Fahrenheit temperatures typically used for ambient air temperature. FTL measures the much higher temperatures achieved inside ceramic kilns required for firing clay and glazes.

Using FTL on a Paragon Kiln

When using FTL on a Paragon kiln, the first step is to set the desired FTL temperature. This is done on the kiln’s control panel by entering the temperature in degrees Fahrenheit or Celsius. According to Paragon’s manuals, FTL firing on their kilns allows temperatures between 1650-2200°F (899-1204°C) [1].

Here are some tips for firing with FTL on a Paragon kiln:

- Make sure to program a hold time at the target FTL temperature. FTL indicates when the kiln has stalled out before reaching the programmed temperature, so having a hold time allows the ware to soak at the highest temperature.

- Increase hold times to allow more time for the kiln to reach temperature. Longer hold times are recommended when firing to higher temperatures with FTL.

- Use kiln wash on shelves and props if firing higher than cone 6 to protect them at extreme temperatures.

- Expect firing times to be longer when using FTL. The increased temperatures require more time for heatwork.

- Avoid opening the kiln until it has fully cooled to protect yourself and the ware from extreme heat.

By programming proper hold times and allowing for longer firing cycles, FTL can enable high fire effects in Paragon kilns. Always consult the manufacturer’s recommendations when using FTL.

FTL Firing Effects

FTL firing affects glazes and clay bodies in distinct ways due to the high temperatures reached. Glazes will become more viscous and fluid at FTL temperatures, enhancing their ability to flow smoothly over the clay surface. This allows glazes to fully cover the piece with an even coating and accentuate subtle textures and shapes in the clay body design.

Clay bodies undergo vitrification at FTL temperatures, which fuses the silica particles together to become impervious to water. The clay becomes denser and less porous the longer it is fired at peak FTL temps. This process of vitrification gives the finished ceramic piece added strength and durability.

Some of the key effects of FTL firing on ceramic works include:

- Enhanced glaze colors and deeper hues

- Smooth, glossy glaze surface

- Tight glaze fit with no crawling or crazing

- Hard, impervious clay body

- Less absorbent and more stain resistant surface

- Increased translucency in certain clays and glazes

- Complex crystalline glaze structures

The intense heatwork of FTL firing allows ceramic artists to expand the visual possibilities of glazes and clay bodies in new creative directions. When utilized properly, FTL temperatures enable pieces with vibrant colors, dazzling surfaces, and superior durability that enhance both aesthetic qualities and functional performance.

FTL vs Other Temperature Scales

FTL stands for Fiberfrax Temperature Limit and is a temperature scale used specifically for high-fire ceramics and kilns. It allows for more precise high-temperature measurements compared to other common temperature scales like Fahrenheit, Celsius, and Kelvin.

While Fahrenheit and Celsius are convenient for measuring temperatures that humans experience in everyday life, they become impractical at the extreme high temperatures used in ceramic firing. For example, cone 10 copper clay requires a temperature of 2381°F. Expressed in Fahrenheit or Celsius, the numbers get very large and difficult to work with.

The FTL scale solves this problem by setting 0°FTL to approximately 1652°F. Temperatures for ceramic firings are then expressed in much more manageable numbers. Cone 10 copper clay requires a temperature of 28°FTL. The FTL scale compresses high temperatures into a more usable range while still allowing for precision.

The main advantage of FTL is for programming and using kilns. Kiln controllers can be programmed easily in FTL. The simplified temperature range allows users to quickly set target temperatures. FTL also offers benefits when testing and calibrating kilns. It allows small adjustments to be made precisely.

For most purposes besides ceramic firing, Fahrenheit or Celsius remain the preferred scales. But for potters and ceramic artists firing at high temperatures, the FTL scale can provide major convenience and usability benefits.

Source: https://www.reddit.com/r/polls/comments/owdql1/which_is_better_fahrenheit_or_celsius/

FTL in Ceramics

FTL is commonly used in ceramics, pottery, and glass fusing to indicate firing temperatures. Ceramic artists and potters rely on standardized temperature scales like FTL to achieve consistent results in their kiln firings. FTL provides specific temperature ranges that are optimized for firing clay and glaze materials.

Some key benefits of using FTL for ceramic firing:

- Allows precise control over firing temperatures for clay bodies and glazes.

- FTL temperature equivalents are calibrated specifically for ceramic processes.

- Standardized system makes sharing firing schedules easy.

- Achieve consistent results by following reliable FTL temperatures.

- Simplifies programming and operating kilns with FTL settings.

FTL is invaluable for ceramic artists as it takes much of the guesswork out of the firing process. By using FTL’s standardized temperatures, potters can focus on creativity rather than worrying about inconsistent kiln results. FTL helps ensure glazes mature properly and clay bodies fully vitrify when fired to the correct temperatures.

FTL Kiln Tips

When firing with FTL on a Paragon kiln, there are some best practices to follow to achieve desired results:

Preheat the kiln slowly, around 100-150°F per hour up to 500°F before turning on the FTL program. This prevents thermal shock to the kiln elements and brickwork. Once 500°F is reached, engage FTL and allow it to ramp up to temperature.[1]

Make sure shelves are stilt-free and pieces are spaced with room for air circulation. Crowding pieces can cause uneven firing.

Place heavier, thicker pieces on bottom shelves where heat work is more intense. Top shelves work best for thinner wares.

Use either cones or kiln sitter for backup fail-safe shutoff in case of FTL thermocouple failure. Running hot can ruin kiln elements.[2]

Soak at top temperature for recommended time to allow heat to fully penetrate work. Soak times help avoid underfiring.

Program a controlled cooling cycle if possible, typically around 200°F per hour down to 1000°F, to prevent cracks and glaze defects.

Keep a kiln log to note firing times, temperatures, and results. Use this data to adjust programs for better outcomes.

Conclusion

In summary, FTL stands for Fired Too Long on Paragon electric kilns. It is a code that appears on the kiln controller display when the firing is taking longer than expected to reach the target temperature. The FTL range on Paragon kilns is typically between 1945-2135°F (1063-1168°C).

While FTL may indicate a problem like low voltage or element failure, it does not necessarily mean the firing has failed. The kiln may just need more time to reach temperature. FTL firings can still successfully vitrify clay and glazes. However, prolonged heat exposure can cause more glass formation, so cooling slowly is advised.

FTL is one of several temperature scales used in ceramic firing, along with °C, °F and cone numbers. Each scale has its pros and cons. FTL is unique to Paragon and provides real-time feedback on firing progress. Understanding FTL codes can help troubleshoot Paragon kilns and optimize ceramic firings.

With some care around voltage, venting and cooling, Paragon kilns with FTL codes can still produce excellent results. While frustrating, FTL does not have to mean a failed kiln firing if the final temperature, hold time and cooling are achieved.