What Element Is Clay Made Of?

Clay’s Main Ingredients

Clay is made of fine-grained minerals like silica, alumina, and iron. The specific composition depends on where the clay is sourced. The most common clay minerals are:

- Kaolinite – This mineral is made up of silica and alumina. It is usually white in color.

- Smectite – This group includes montmorillonite and contains silica, alumina, and magnesium or iron. Smectite clays absorb water easily and expand when wet.

- Illite – This mineral contains silica, alumina, potassium, iron, and magnesium. Illite has a flaky structure.

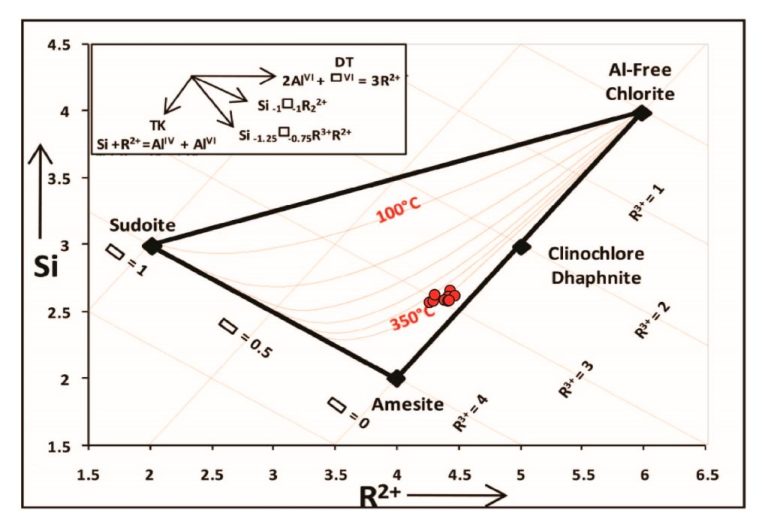

- Chlorite – This group includes minerals like chamosite and clinochlore. They contain silica, alumina, magnesium, and iron.

The percentage of each mineral present gives the clay its unique properties. Clay deposits located in different geological formations and regions will have varying mineral compositions based on how they were formed over time.

How Clay Forms

Clay forms from the chemical weathering and erosion of rocks over long periods. Environmental factors like water, temperature, and pressure impact clay formation. The weathering process breaks down feldspar, a mineral found in igneous and metamorphic rocks, into very fine particles. Over time, the fine particles are transported by water or wind and deposited in the soil or water bodies.

The small size and shape of the clay particles, typically less than 0.002 mm, give clay unique properties. Clay particles carry an electrostatic charge that causes them to bond tightly together when wet. However, the bonds are weak enough to allow the particles to slide past each other when stress is applied, making clay flexible and moldable.

As clay deposits accumulate from transported materials, the pressure squeezes out water and compacts the deposits. Burial beneath subsequent layers of sediment increases the pressure and temperature, consolidating the clay into sedimentary rock. Under the right conditions, this rock can then be transformed into shale or slate.

Physical Properties

Clay’s physical properties arise from its unique structure at the microscopic level. Clay consists of small, flat, platy particles that are roughly one thousand times smaller than a grain of sand. These tiny platelet particles give clay some distinctive characteristics:

– Plasticity: When clay is mixed with water, the water molecules slide between the flat clay particles and allow them to slip and slide over one another. This gives clay a smooth, malleable, plastic texture that can be molded into shapes.

– Shrinkage: As clay dries, the water evaporates and the clay particles pack more tightly together. This causes the clay to shrink in size. The amount of shrinkage depends on the clay body composition.

– Strength: When clay is fired in a kiln, the high heat chemically alters the clay particles and fuses them together into a strong, ceramic material. The flat shape and arrangement of the particles give clay its formidable strength.

So in summary, the small, platy, and flexible nature of clay particles at the microscopic level give rise to the unique physical properties of plasticity, shrinkage, and strength that make clay such a versatile material for crafting and construction.

Chemical Properties

Clay’s chemical properties are what make it so useful. Clay particles develop charges by inheriting ions from surrounding waters. The charges allow clay particles to attract and hold onto certain ions and molecules. This property is known as cation exchange capacity.

Clay’s cation exchange capacity allows it to absorb and retain nutrients like potassium, calcium, and magnesium, as well as other beneficial elements. This makes clay very important for agricultural uses, as it can hold nutrients and provide them slowly to plants. The nutrients are held in reserve until plants can absorb them, providing long-term fertilization.

Clay also readily absorbs water and retains it, because the water molecules are attracted to the charged sites on the clay particles. The absorption and retention of water and nutrients gives clay soil moisture-holding and fertility benefits. However, too much water retention can lead to drainage issues in pure clay soils.

Clay’s excellent absorption qualities also allow it to trap heavy metals and contaminants in the environment. This can be useful for remediation of contaminated sites, where the toxins become fixed to clay particles so they cannot migrate. However, agricultural clays may absorb and accumulate heavy metals from repeated fertilizer applications over time. Testing is important to monitor contaminant levels.

Types of Clay

There are several common types of clay that have unique properties and mineral compositions. The most abundant clays include:

-

Kaolinite – This clay has a flaky, layered structure. It is non-swelling and does not absorb much water. Kaolinite has high heat resistance and is often used for porcelain and ceramics.

-

Montmorillonite-smectite – This type of clay swells considerably in the presence of water. It is very absorbent and plastic. Montmorillonite has many applications including cat litter, medicine, and cosmetics.

-

Illite – Illite has a flaky, mica-type structure. It is moderately absorptive and shrinks when dried. Common uses for illite clay include in ceramics and cements.

-

Chlorite – This clay has a fine, scaly structure. It is elastic but not very plastic. Chlorite is used for bonded sands in molds and pet waste absorbents.

The specific mineral content of each clay type gives it distinct properties that make it useful for different applications.

Uses of Clay

Clay has had an extraordinary range of uses for thousands of years. Due to its abundance, versatility, and ability to be molded when wet, baked hard when dry, and blended with other minerals, clay has served people across civilizations and cultures.

Some of the most common uses of clay through history and today include:

- Pottery – Clay can be shaped while wet and turned into art, dishes, tiles, pipes, and more when fired in a kiln.

- Bricks – Mixing clay with sand or other additives and baking into bricks has allowed construction of buildings, roads, and infrastructure.

- Cement – Clay is an essential ingredient in Portland cement along with limestone, shells, and other materials.

- Paper – Specialty clays are used to coat paper to create glossy surfaces and improve printability.

- Kitty litter – Absorbent clays like bentonite are excellent at soaking up pet wastes.

- Cosmetics – Kaolin clay is used in some soaps, facial masks, and bath powders.

- Pharmaceuticals – Clays can be used to deliver drugs, remove toxins, and treat stomach ailments.

In modern times, over 25 million tons of clay are produced each year in the United States alone. The unique and useful properties of clay will likely ensure it remains an essential material for human civilization into the foreseeable future.

Clay vs. Mud

Clay and mud may seem similar, but they have some key differences in their composition. Mud is a mixture of clay, silt, sand, and organic matter, while pure clay contains more than 50% clay minerals. This means mud has a wider range of particle sizes compared to pure clay.

The higher clay mineral content gives clay some different properties than mud. Clay is sticky and malleable when wet, can harden when fired at high temperatures, and swells when exposed to moisture. Mud may crack and dry into dirt, but lacks the plasticity and hardening ability of clay.

Mud has a looser, heterogeneous mixture of particle sizes ranging from large sand grains to microscopic clay particles. This range allows mud to hold more moisture but makes it less cohesive. The clay mineral particles in pure clay are extremely small and uniform in size, allowing them to pack tightly together and form strong bonds that give clay its unique properties.

So while mud and clay may look similar on the surface, the composition and particle size distribution result in some notable differences in their characteristics and uses.

Clay Deposits

Clay deposits are found across the world, often in tropical and subtropical areas where weathering of rocks forms clay minerals. The largest producers of clay include Brazil, China, and India. These countries contain abundant deposits due to their wet, tropical climates and weathering of feldspar-rich rocks.

China, the leading producer, mines a special type of clay called kaolin in the southeastern Jiangxi province. Kaolin has a high whiteness index and fine particle size, making it ideal for ceramics and paper production. India also mines large amounts of kaolin, along with other clays like ball clay and bentonite.

Brazil’s main clay deposits are located in the Amazon region, which provides ideal conditions for chemical weathering and clay formation. The country is the largest exporter of kaolin and accounts for over 13% of global production. Other major clay producers include the United States, Germany, Turkey, and Mexico.

While commercial clay deposits are focused in tropical areas, clay can be found across most regions. Glaciers and rivers transport weathered clay minerals far from their origin. Backyard clay pits used by potters also obtain clay from more local sources than commercial operations.

Clay Production

Clay is typically surface mined, though underground mining is also used. Surface mining involves removing soil and rock with heavy machinery to expose the clay deposits underneath. The clay is then extracted, loaded into trucks, and transported to a processing plant.

Underground mining utilizes shafts and tunnels to reach deeper clay deposits. Explosives are often used to break up clay from the walls of the tunnels. The broken clay is hauled to the surface for additional crushing and processing.

At the processing plant, the clay goes through several steps to prepare it for use. It is crushed, ground, and screened to achieve the desired size and texture. The clay may also be purified, mixed with other materials, and undergo chemical changes through firing at high temperatures. This enhances certain properties in the clay.

The processed clay is then bagged, packaged, and shipped to manufacturers that will use it to produce ceramics, brick, cement, and other clay products. Careful clay production and processing ensures the clay has the expected chemical and physical properties for its intended applications.

Environmental Considerations

While clay is abundant, mining and using it impacts the environment through land use, habitat loss, and water use. Responsible sourcing is important. Extracting clay often involves clearing land, removing vegetation and topsoil, and disrupting ecosystems. This can negatively impact habitats and biodiversity. Clay mining may also require large amounts of water, which can strain local water resources.

There are ways the clay industry can reduce its environmental footprint. Using greener mining techniques, reclaiming mined land for other uses, recycling water, controlling dust and erosion, and minimizing energy and water consumption during production are all important. Companies and consumers sourcing clay responsibly helps ensure clay’s abundance continues while protecting nature.