What Equipment Do I Need To Make Gold Jewelry?

Gold jewelry making is an enjoyable and rewarding hobby that allows you to design and create your own personalized jewelry pieces. With some basic equipment and skills, almost anyone can get started making their own gold jewelry at home. The type of gold jewelry you can make includes rings, bracelets, necklaces, earrings, pendants, and more.

When getting started with gold jewelry making, the essential equipment you need falls into several main categories: a jeweler’s workbench, saws and files for cutting/shaping, hammers/anvils for forming metal, soldering tools, pliers and hand tools, and polishing/finishing supplies. This introductory guide will provide an overview of the basic goldsmithing tools and supplies needed to equip your workspace and start crafting beautiful gold jewelry creations.

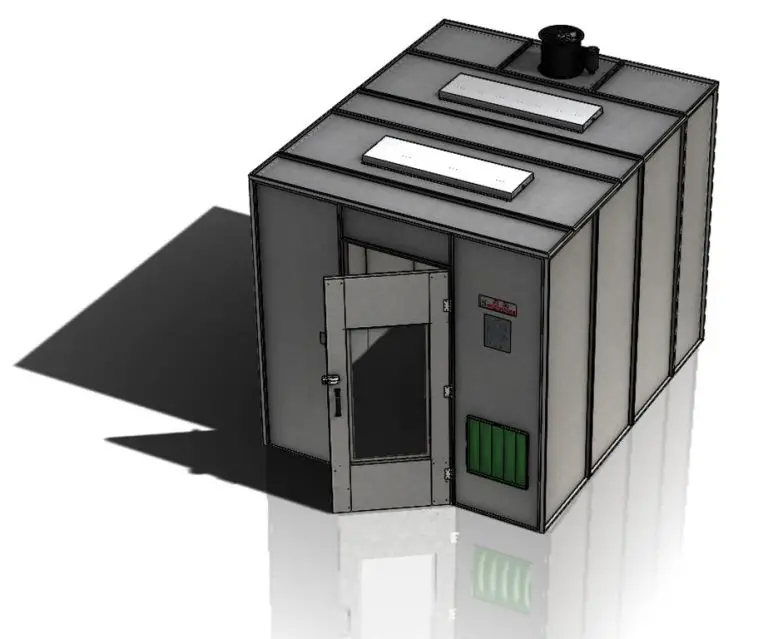

Jeweler’s Bench

A jeweler’s bench is the main working surface for creating jewelry. The purpose of the bench is to provide a sturdy, well-lit, and organized workspace for jewelry making and repair. There are several considerations when choosing or setting up a jeweler’s bench:

Purpose of Bench

The bench should be sturdy enough to handle hammering and filing without wobbling. Hardwood or steel tops are best for absorbing impact and preventing damage over time. The height should sit at or slightly above the jeweler’s elbow height while seated to prevent back strain [1].

Surfaces

Bench surfaces may be wood, steel, granite, or other materials. Wood provides some shock absorption but can dent or warp over time. Steel offers durability for hammering. Granite is also extremely durable but may damage tools if used for hammering. Multiple interchangeable surfaces can accommodate different tasks [2].

Lighting

Proper lighting is essential for detailed jewelry work. Bench lamps, magnifying lenses with built-in lights, and overhead lights are common options. Gooseneck lamps allow adjustable positioning. Daylight-balanced bulbs provide the best color rendering.

Storage

Built-in drawers, shelves, and pegboards keep tools and materials organized and easily accessible. Drawers store small items securely while shelves neatly display larger tools, kits, and supplies. Pegboards efficiently utilize vertical space.

Ventilation

Soldering and other jewelry processes produce fumes, so ventilation is important. Position the bench near a window or use a fume extractor. Proper ventilation improves comfort and air quality.

Jeweler’s Saw

A jeweler’s saw is one of the most important tools for cutting and shaping metal and other materials when making jewelry. The purpose of a jeweler’s saw is to enable detailed and intricate cuts with high precision using very fine saw blades.

There are several types of jeweler’s saws available:

- Frame saws: These feature an adjustable cast metal frame that holds the blade under tension. Frames come in various sizes like 4″, 5″ or 6″.

- Coping saws: Usually feature wooden frames and are used for cutting curves and interior shapes.

- Scroll saws: Designed for more detailed, intricate cuts and feature very fine blades.

Jeweler’s saw blades come in various sizes like 2/0, 4/0 or 6/0 and materials like high carbon steel or bimetal. The right blade size and type depends on the thickness and hardness of the material being cut. Using lubricants like beeswax or cutting fluid helps prolong blade life.

Some popular brands for high quality jeweler’s saws are Grobet, Lindstrom and Puffin.

Jeweler’s File Set

Files are essential tools for goldsmithing and jewelry making. The purpose of jeweler’s files is to smoothly shape, contour, and finish metal surfaces. Jewelery files come in a variety of shapes, cuts, and sizes for different uses.

Some common types of jewelers files include:1

- Needle files – thin, pointed files for detailed work

- Barrette files – flat, tapered files

- Half-round files – rounded on one side, flat on the other

- Square files – square cross section

- Round files – rounded cross section

- Warding files – thick, curved files

The cut of the file refers to the pattern of teeth. Some common cuts are single cut, double cut, and curved cut. Using the proper cut and stroke is important to file properly without damaging the workpiece.

A quality set of jeweler’s files in a range of shapes, cuts, and sizes is essential for detailed metal shaping and finishing in jewelry making.

Jeweler’s Hammer

A jewelry hammer is perhaps one of the most essential tools for making jewelry. Jeweler’s hammers come in various shapes and sizes for specific purposes in jewelry making. Using the proper type of hammer allows you to shape, texture, and work your metal with precision and control.

Some common types of jeweler’s hammers include:

- Ball peen hammer – An all-purpose hammer good for basic forming and shaping of metal.

- Chasing hammer – A hammer with a flat, square face used for detailed imprinting and texturing on metal surfaces.

- Planishing hammer – A hammer with a slightly rounded, smooth face used to refine and smooth metal surfaces.

- Raising hammer – A hammer with a domed face used to shape metal into curved and hollow forms like bowls.

When using a jeweler’s hammer properly, rest your elbow on the bench to control the hammer’s movement. Use light, accurate taps instead of heavy strikes. Use an anvil or bench block to support the metal being worked. Select the type of hammer face and weight suitable for the technique. With practice, hammers allow great control and intricacy in metal shaping and decoration.

For more details on types of hammers and hammer techniques, check out this guide: [1]

[1] https://www.interweave.com/article/jewelry/jewelry-tools-101-guide-to-jewelry-making-hammers/

Anvil and Bench Block

Anvils and bench blocks are essential tools that provide hard, stable surfaces for hammering and shaping metal. They are made from hardened steel or cast iron to withstand repeated impact without deformation.

The purpose of an anvil is to provide an opposing surface that the metal can be hammered against to shape it. Anvils typically have a flat surface as well as various shaped horns that can be used to form curves or bends in the metal. Bench blocks serve a similar purpose but are smaller blocks that can be anchored to the workbench.

It’s important that both the anvil and bench block are firmly secured so they don’t bounce or move when hammering. As expert jewelers point out, “When everything jumps around, you lose energy and accuracy” (source). Bench blocks can be anchored using bench pins, clamps, or adhesive pads. Anvils need to sit firmly on a heavy, solid surface or stand.

Using the proper sized anvil or bench block for the jewelry work is also important. Large anvils are best for blacksmithing but smaller anvils and bench blocks give jewelers more control over shaping delicate metal pieces.

Pliers

Pliers are an essential tool for holding and shaping metal when making gold jewelry. The key purpose of pliers is to provide grip and leverage when manipulating wire, sheet metal, and other materials. There are several different types of pliers that serve specific functions:

Chain nose pliers are versatile pliers with tapered, flat smooth jaws. They can be used for many basic tasks like opening and closing jump rings, bending wire, holding small components, and more. Chain nose pliers allow for precise work in tight areas. See this source for more details.

Round nose pliers have tapered round jaws used to create loop and circle shapes in wire. The rounded interior of the jaws allows bending wire at various diameters. Round nose pliers are essential for making the links in chains and jump rings.

Flat nose pliers have broad, flat jaws that provide maximum surface contact on the workpiece. They are used to bend, shape, and cut soft metals. The broad jaws help prevent marring soft metals when grip is applied.

There are other specialized pliers like half-round pliers, but this covers the most essential types. Selecting the right pliers for the task is key for efficiency and quality results when making gold jewelry.

Misc Hand Tools

Beyond basic shaping and cutting tools, goldsmiths require a variety of other hand tools to work with jewelry and precious metals. Some key miscellaneous tools include:

Tweezers are essential for handling small parts and stones. Slanted tip tweezers allow precision holding from many angles. Flat tip tweezers have a stronger grip for moving heavier items.

Calipers and micrometers precisely measure thicknesses and diameters of metal stock and components. Digital calipers offer accuracy down to 0.01 mm for detailed work. Ring mandrels check sizing and form rings.

A jeweler’s saw frame securely holds small saw blades for intricate cutting work. Saw blades come in various sizes for curves and intricate shapes.

Punches make divots and textures in metal using interchangeable tips. Center punches prep indentation starting points.

Scribes and awls mark lines and dots without cutting metal. Sharpened scribe tips etch very fine lines.

Mallets hammer metal through forming tools without marring surfaces. Bench pins hold work securely while hammering and sawing.

Jeweler’s vices and clamping tools provide stable, hands-free grip of workpieces for soldering and other tasks.

Magnifying lenses like jeweler’s loupes enlarge views of small items. Quality lighting is crucial for seeing detail work.

Soldering Equipment

Soldering is an essential part of jewelry making for joining metals together. The main pieces of soldering equipment you’ll need are a torch, solder, flux, and tweezers.

Torches are used to generate the heat required to melt the solder and fuse metal components together. Common types of torches used for jewelry making include butane micro torches and propane/MAPP gas torches. Butane micro torches are inexpensive, portable options well-suited for small jewelry projects. Propane/MAPP gas torches burn hotter and are recommended for larger-scale soldering projects.1

For the solder itself, you’ll need to select a solder alloy that closely matches the karat of the metals being joined. Common solder types include hard, medium, and easy/soft solder. Solder also comes in wire, sheet, and paste form. Flux aids in solder flow and bonding of the metals. Tweezers and clamps are helpful for holding components in place while soldering.

Safety equipment like fireproof work surfaces, protective eyewear, and well-ventilated work areas are also necessities for soldering. Investing in quality soldering tools and taking proper safety precautions allows jewelry makers to efficiently join metals and create durable pieces.

Polishing and Finishing

Once your gold jewelry pieces are fabricated, you’ll need equipment to polish and finish them to a brilliant shine. This usually involves polishing compounds and buffing wheels or tumblers.

Polishing compounds like tripoli and rouge are abrasive pastes used with buffing wheels to smooth and polish gold. Start with a coarser compound like tripoli to remove file marks and shape details. Then use a finer rouge compound for a final high-shine polish. Buffing wheels are made of materials like cotton, felt, or leather and attach to a flexshaft or bench lathe.

Rotary tumblers provide another option for polishing, especially for cleaning castings or finishing large batches of pieces. Stainless steel shot, burnishing liquid, and soap are placed in the barrel along with the jewelry. As the barrel rotates, the media smooths and polishes the surfaces. Different tumbler models offer features like digital timers and variable speed control.

No matter the polishing method, it’s critical to clean jewelry thoroughly after buffing and tumbling. Any leftover compound can dull the finish over time. An ultrasonic cleaner or steam cleaner will remove polishing media from intricate areas.

With the right compounds, tools, and techniques, you can achieve a brilliant, professional polish on your handcrafted gold jewelry creations. A polished finish not only enhances beauty but also increases value and perceived quality. Taking time to properly polish your pieces is one of the most important steps before sale or wear.