What Happens When Relay Goes Bad?

What is a Relay?

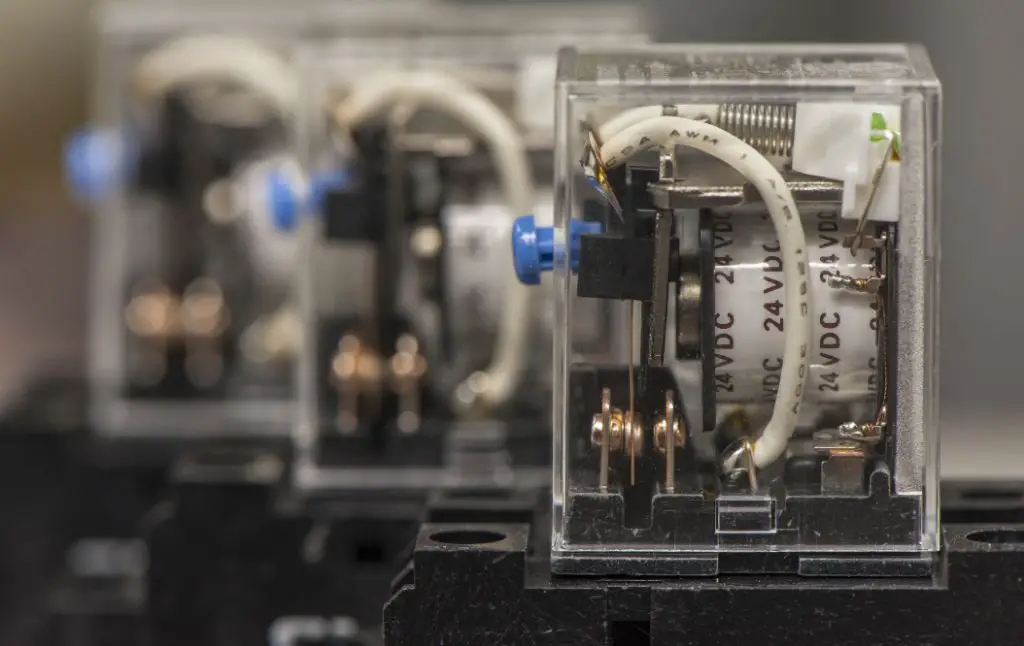

A relay is an electrically operated switch that uses an electromagnet to mechanically open or close electrical contacts and control a circuit. Relays consist of a coil that receives an electric signal and converts it into mechanical force that actuates the switch contacts. They allow a low power circuit to control a higher power circuit safely and reliably.

Some common types of relays include:

- Electromechanical relays – Have movable parts and use an electromagnet to move switch contacts. They are relatively slow but can handle high current/voltage.

- Solid state relays – Have no moving parts. They use semiconductor switching devices like transistors or SCRs instead of mechanical contacts. Solid state relays are very fast and reliable but limited in voltage/current handling.

- Reed relays – Use a magnetic coil around a reed switch to actuate contacts. They are very small and provide isolation between control and load circuits.

Relays work by having an input coil circuit that when energized creates a magnetic field. This magnetic field pulls a movable armature or reed switch to change the state of the output contacts, either closing the normally open contacts or opening the normally closed contacts. This allows a small control signal to turn on or off a much larger load circuit.

Relay Failure Modes

There are three main causes of relay failure:

Mechanical Failure

Mechanical failure occurs when there is wear and tear on the moving parts of the relay over time. This includes failure of the spring mechanism, contact arcing and welding, and issues with the coil and core.1

Electrical Failure

Electrical failures happen when the relay is subjected to voltage or current spikes that exceed its ratings. This can cause burning or pitting of the contacts.2

Environmental Causes

Environmental factors like high temperature, humidity, vibration, and dust can lead to relay failure over time. Heat and dirt can cause insulation breakdown. Vibration can loosen connections.3

Effects of Stuck Relays

One of the most common issues that occurs when a relay fails is that it becomes stuck or will not release. This results in the relay remaining constantly on or “closed.” Some of the major effects of a stuck relay include:

Motor staying on – If a power relay controlling a motor or device becomes stuck in the closed position, it will cause the motor to remain running constantly. This can quickly drain the battery in a vehicle and can also result in overheating and damage to the motor or device.

[http://community.onion.io/topic/784/resolved-relays-sticking]

Lights staying on – Similarly, if a lighting relay fails in the closed position, it will leave lights or accessories switched on even when they are supposed to be off. This will drain the battery.

Drain on battery – Because a stuck relay keeps loads and devices powered on even when they should be off, it can very quickly drain a vehicle’s battery. This can leave you stranded if the battery fully discharges when the vehicle is parked.

Effects of Intermittent Relays

An intermittent relay is one that makes and breaks contact randomly. This can lead to a variety of frustrating symptoms as equipment turns on and off unpredictably. Some common effects of an intermittent relay include:

- Lights flickering – If a relay in the lighting circuit starts making intermittent contact, the lights may blink or flicker randomly. This is often most noticeable with dashboard backlighting or headlights.

- Problems starting engine – An intermittent starting relay can cause issues with starting the engine. It may try to crank but not turn over, or start sometimes but not others.

- Equipment turning on and off – Components like radios, headlights, or power windows may turn on and off seemingly at random due to a faulty intermittent relay. This occurs as the relay makes and breaks contact.

Tracking down an intermittent relay can be challenging since the issues come and go. But identifying the pattern of affected components can help narrow down the faulty relay. Replacing the intermittent relay with a new unit will resolve the random power issues.

Finding the Faulty Relay

When a relay has failed, the first step is to locate which specific relay is causing the issue. There are a few methods for testing relays to find the faulty one:

Visual Inspection: Closely examine the relay for any signs of damage like cracks or burnt contacts. Check that the relay is properly seated in the socket. Look for loose connections to the relay. Visually inspecting the relay and connections can sometimes reveal the problem.

Testing with a Multimeter: Use a multimeter to check for continuity across the relay coil terminals when power is applied. No continuity means the coil is damaged. Check for expected continuity on the relay switch terminals when the coil is energized and de-energized. Unexpected results pinpoint issues with the relay contacts. Refer to this guide for detailed multimeter testing procedures.

Monitoring Current Draw: Use a clamp meter to measure current draw on the relay feed wire. A faulty relay may draw significantly more or less current than expected. Compare measurements to known good relays of the same type to identify anomalies.

By visual inspection, multimeter testing, and current draw monitoring, the specific faulty relay can be identified for replacement.

Replacing a Relay

Locating the faulty relay is the first step in replacing it. Relays are often located in the fuse box or power distribution center. Refer to the vehicle’s service manual to identify the specific relay that needs to be replaced. Some relays are plug-and-play while others are hardwired and will need to be removed from the relay socket.

To remove the old relay, carefully pull it straight out from the socket. In some cases, relays can get stuck in the socket. Using a small flathead screwdriver, carefully pry underneath the relay to help dislodge it. Take care not to damage the relay socket when removing the old unit. If the relay does not come out with gentle prying, stop and reassess the situation before forcing it.

Before installing the new relay, compare it to the old unit to ensure it has the same number of pins and electrical specifications. Gently push the new relay straight into the socket until it clicks into place. Ensure the relay is properly seated in the socket so that the electrical pins make good contact.

According to Pickering Test, relays that are glued in place can be removed by attaching an item to the top of the relay with a suitable contact adhesive. As an alternative, the relay can be drilled and a self-tapping screw used to remove it.

Preventative Maintenance

Preventative maintenance is key to ensuring relays continue to operate properly over their lifetime. Some important preventative maintenance tasks include:

- Inspecting connections – Check that wiring terminals are tight and corrosion free. Loose or corroded connections can cause erroneous readings.

- Checking seals – Ensure the relay case and any seals are intact. Broken seals expose the internal components to contaminants and moisture.

- Testing periodically – Relays should be tested regularly to verify correct operation. Testing can reveal failing components before they lead to complete failure.[1]

Following the manufacturer’s recommended maintenance schedule and procedures can maximize relay lifespan. If internal components become contaminated or corroded, they may need replacement.

Types of Replacement Relays

When it comes time to replace a faulty relay, vehicle owners have two main options – OEM relays or aftermarket relays. OEM (original equipment manufacturer) relays are made by the manufacturer of the vehicle and are identical to the relay that originally came with the car or bike when new. Aftermarket relays are produced by third-party companies and are not made by the original vehicle manufacturer.

There are pros and cons to both OEM and aftermarket replacement relays:

OEM Relays

OEM relays from the vehicle manufacturer are often considered the “safest” replacement option since they are made to the exact specifications and tolerances required by the vehicle maker. OEM parts ensure proper fit and function. However, OEM relays also tend to be the most expensive option.

According to one forum discussion, OEM relays for some vehicles can cost upwards of $70, whereas aftermarket versions may only be $20-30 (source: https://www.svrider.com/threads/starter-relay-oem-or-aftermarket.142513/).

Aftermarket Relays

Aftermarket relays provide a more affordable alternative and are widely available. However, quality can vary greatly between aftermarket relay brands. Lower cost relays may not provide the same performance or longevity as OEM. There are reputable aftermarket brands that manufacture relays to meet or exceed OEM specifications.

According to one thread, electronics like relays don’t always pair well with aftermarket parts. For critical components like the main fuel relay, they recommend sticking with factory OEM (source: https://honda-tech.com/forums/honda-civic-del-sol-1992-2000-1/main-fuel-relay-oem-aftermarket-2810229/).

In summary, OEM relays may cost more but provide reliable performance and durability. Aftermarket can work if choosing a quality brand but results may vary.

Relay Failure Case Studies

One common symptom of a faulty relay is the starter staying engaged after the engine starts running. This occurs when the starter relay fails in the closed position, allowing constant power to the starter motor. As noted in this article, even low-level electrical issues can cause relay failure.

A relay controlling the blower fan not working can also indicate a failed relay. The fan relay may fail open, interrupting power supply to the blower motor. As relays age, their contacts can become oxidized or worn, leading to intermittent operation or failure.

Flickering headlights point to a potential problem with the headlight relay. Like other relays, the vibration and heating/cooling cycles in a car can cause the headlight relay to fail over time. Replacing the faulty relay often resolves flickering headlights.

When to Call a Professional

If the faulty relay is part of an important safety system like anti-lock brakes, airbags, or headlights, it’s best to have a professional mechanic or technician diagnose and replace the relay. According to InterConnect Wiring, “After 25 years, relays, wires, and connectors tend to get old and start to show signs of problems, such as relays sticking.” [Source] Failing safety systems can lead to dangerous situations, so it’s not worth attempting a DIY repair.

For complex computerized vehicles, the relay circuits are integrated into the car’s computer network. Replacing a relay on newer cars requires specialized tools to access the car’s computer diagnostic system. If you are unsure how to diagnose or replace a failed relay, it’s safer to have a professional mechanic troubleshoot the electrical system. They have the equipment and expertise to efficiently find and replace the bad relay.

In general, if you don’t have electrical system knowledge or are unsure of how to safely replace a relay, call a professional technician. They can properly diagnose the fault, replace the bad relay, and ensure other components were not damaged. This avoids accidentally swapping out good relays or failing to address the root cause. According to Fleet Maintenance, “When parts are replaced and they fail repeatedly because the root cause was never found, it can increase and extend vehicle downtime.” [Source] Calling a professional prevents wasting time and money on unnecessary repairs.