What Is A 1095 Carbon Steel Equivalent To?

What is 1095 Carbon Steel?

1095 carbon steel is a high carbon plain carbon steel with around 0.95% carbon content (Source: https://www.azom.com/article.aspx?ArticleID=6561). It contains 0.90-1.03% carbon and 0.30-0.50% manganese as the main alloying elements (Source: https://www.matweb.com/search/datasheet.aspx?MatGUID=8bab8f67515740b0af82c9b119259b80).

1095 carbon steel is characterized by high hardness and strength, but it also tends to be brittle due to the high carbon content (Source: https://www.suppliersonline.com/propertypages/1095.asp). It achieves high hardness in the quenched and tempered condition, typically around HRC 60-62.

Common applications of 1095 carbon steel include knives, cutting tools, springs, and high-strength parts where hardness is critical. It is commonly used to make knife blades due to its ability to take and hold an acute edge (Source: https://www.azom.com/article.aspx?ArticleID=6561).

Key Differences Between Steel Grades

The primary difference between steel grades is the amount of carbon contained in the alloy. Higher carbon steels, like 1095, typically contain between 0.60-1.00% carbon. Lower carbon steels, such as 1018, usually have between 0.15-0.25% carbon source.

Carbon levels have a significant impact on steel’s properties. Increasing carbon content makes steel harder and stronger, but less ductile. Higher carbon steels like 1095 can be heat treated to very high hardness levels, over 60 HRC. Lower carbon steels stay softer and more weldable. Their hardness generally tops out between 20-30 HRC source.

Besides carbon, other alloying elements are added to influence steel’s properties. Chromium increases corrosion and wear resistance, while manganese improves hardenability. Nickel is added for toughness and ductility. Molybdenum helps with strength and machinability source.

Steels Similar to 1095 Carbon Steel

There are several steels that have properties comparable to 1095 carbon steel and can serve as equivalents in certain applications:

O1 Tool Steel

O1 tool steel has a similar carbon content to 1095, ranging from 0.9-1.0%, but also contains about 1% manganese and 0.5% tungsten [1]. This gives O1 higher wear resistance and toughness compared to 1095. It is easier to sharpen and polish than 1095, but may not hold an edge as long. O1 works well for knives, cutting tools, and other applications requiring good edge retention.

52100 Bearing Steel

52100 is another high carbon steel with around 1.0-1.1% carbon content. It contains 1.3-1.6% chromium as an alloying element [2], giving improved corrosion resistance over 1095. 52100 takes extremely high hardness with heat treatment, but is less tough and more difficult to sharpen. It is commonly used for ball bearings.

W1 Tool Steel

W1 has a carbon content of 0.9-1.0%, with about 1% tungsten and 0.5% manganese added [1]. This improves wear resistance compared to 1095. W1 is tougher than 52100 or O1. It holds an edge well and is easier to sharpen than 1095 while having similar hardness capability. W1 is commonly used for cutting tools.

15n20 Carbon Steel

15n20 is a low alloy carbon steel with a carbon content of 0.15-0.2% [3]. This gives it lower hardness and wear resistance than 1095, but increased toughness. 15n20 is machinable, weldable and suitable for carburizing. It is used for springs, fasteners, and structural components requiring good shock resistance.

Comparing Grades to 1095 Carbon Steel

1095 is considered a high carbon steel, containing approximately 0.95% carbon content. This high carbon content gives 1095 exceptional hardness and edge retention properties. However, other steel grades have their own advantages and disadvantages compared to 1095:

O1 Tool Steel

O1 has slightly less carbon than 1095, with ~0.9% carbon content. It also contains 1.0% chromium and 0.5% manganese. The chromium increases hardenability and wear resistance. O1 can be brought to a higher hardness than 1095, up to 66 HRC, providing better edge retention (source). However, 1095 is easier to sharpen. O1 has more alloying elements that can abrade sharpening stones (source).

1075 and 1084

1075 and 1084 have slightly less carbon than 1095, around 0.75% and 0.80-0.84% respectively. This makes them a bit softer and tougher than 1095, but may reduce edge holding ability. 1084 is readily available and inexpensive, perhaps even more so than 1095 (source). So 1084 can be a good budget alternative to 1095.

Heat Treating 1095 and Equivalents

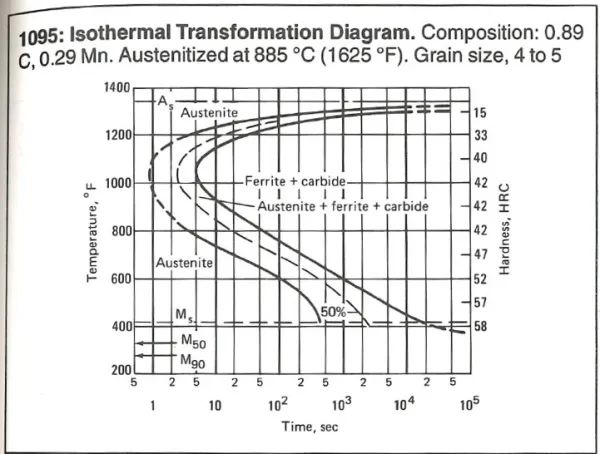

Heat treating is a critical process for 1095 carbon steel to achieve the desired hardness and toughness. The key steps are normalizing, quenching, and tempering.

Normalizing involves heating the steel to a temperature between 1,550°F and 1,650°F and allowing it to air cool. This reduces internal stresses and improves machinability. According to this Blade Forums post, normalizing is an optional but recommended first step.

The next step is quenching, which hardens the steel. 1095 steel should be heated to between 1,450°F and 1,500°F, then quickly quenched in oil or another rapid quenchant. The rapid cooling brings the steel to its hardest state.

Finally, tempering relieves some hardness to improve toughness and reduce brittleness. For 1095, temper twice at temperatures between 350°F and 400°F for two hours each time. This achieves a hardness around 60 HRC.

The entire heat treating process for 1095 requires precise control of temperatures and timing. Other steels have different hardening and tempering requirements. For example, 1084 steel can be heated to between 1,450°F and 1,500°F before an oil quench and tempered around 400°F to achieve similar hardness.

Working with 1095 and Similar Steels

1095 and comparable steels are carbon steels, which contain around 0.9-1.0% carbon. This gives them hardness but also makes them more challenging to machine compared to lower carbon steels. Here are some tips for working with 1095 and similar grades:

For machining, rigid setups and sharp tooling are essential. Carbide tooling and adequate coolant will help achieve good surface finishes while avoiding work hardening. Feed rates should be slower than for mild steel. The Machining Data Sheet recommends starting at 150 SFM and 0.005 IPR feed rate.

Grinding works better than machining for removing large amounts of material efficiently. Use aluminum oxide grinding wheels. For sharpening, belt sanders or grinders with fine grit wheels produce a keen edge. Polish with increasingly finer grit sandpaper or buffing wheels.

For heat treating, 1095 responds well to quenching and tempering. Harden the steel by heating to critical temperature (1475-1550°F) and quenching in oil or water. Temper immediately while steel is still warm. Tempering reduces brittleness and allows customizing the hardness. Typical tempering temperatures are 300-600°F.

Best practices for finishing include cleaning the steel thoroughly after heat treating, then applying a protective coating of oil or wax to prevent corrosion. For handles, wood, plastic, or stacked leather provide a comfortable grip.

Example Applications

1095 carbon steel is commonly used for making knife blades. It has good edge retention and is easy to sharpen, making it a popular choice among knife makers and enthusiasts. Many custom, handmade, and production knives feature 1095 blade steel.

In addition to knives, 1095 finds use in other cutting applications like chisels, plane irons, and various woodworking tools. The hardness and wear resistance allow it to hold a sharp edge through repeated use and impact. Quality chisels and woodworking tools often rely on 1095 or equivalent steels.

Beyond knives and woodworking, 1095 and comparable steels have roles in industrial tool and die applications. The steel can be machined, heat treated, and tempered to suit specific needs. Applications include punches, milling cutters, drill bits, gauges, and other fabricated parts requiring hardness, strength, and durability.

Sources:

https://www.amazon.com/1095-high-carbon-steel-knife/s?k=1095+high+carbon+steel+knife

https://agrussell.com/1095-high-carbon-steel

When to Choose 1095 vs. Alternatives

1095 carbon steel is valued for its combination of hardness and toughness from the high carbon content. According to bladesmiths (https://www.americanbladesmith.org/community/materials-and-supplies/o1-vs-1095-for-finish-work/), 1095 can be hardened up to around 64 HRC, while having decent toughness for a high carbon steel. This makes it suitable for many knife applications where hardness for edge retention and wear resistance is needed, but not so brittle that the blade can’t withstand impacts.

Compared to alternatives like O1 or 52100, 1095 has lower chromium content so it doesn’t form as many wear resistant carbides. According to knife makers discussions (https://www.reddit.com/r/knifemaking/comments/va1y08/o1_vs_10751084_vs_1095/), this can make 1095 easier to sharpen than those higher alloy steels. The tradeoff is that edge retention may not be as good. O1 and 52100 can potentially get up to 66 HRC as well.

1095 is a good choice when a very pure high carbon steel is needed for properties like ease of sharpening or compatibility with traditional Damascus patterning for specialty blades (https://www.bladeforums.com/threads/o-1-tool-steel-vs-1095-high-carbon-steel.1386205/). It’s essential to properly heat treat 1095 to get optimal hardness and 1095 may need more frequent sharpening than alloys with more carbides. But for many knifemakers, the purity and lack of carbides is seen as an advantage for certain uses.

Recommendations for Substitution

When looking for a substitute for 1095 carbon steel, there are a few key factors to consider. According to this source on knife steels, the most important properties are hardness, toughness, edge retention, corrosion resistance, and machinability/grindability. 1095 is known for its hardness and decent toughness, but is not very corrosion resistant. Here are some recommendations for substitution:

For a substitute with better corrosion resistance but similar hardness, A2 or O1 tool steels make good options. According to this comparison of knife steels, A2 has excellent edge retention and hardness while being more corrosion resistant than 1095. O1 has slightly less hardness than 1095 but the bonus of stain resistance. Both can achieve hardness levels of around 60 HRC, making them good alternatives for knives or cutting tools.

If even higher toughness is desired, 52100 steel is an excellent choice. With similar hardness potential to 1095 but higher impact strength, 52100 makes tougher knives that can withstand more abuse. It does have less wear resistance than 1095, so for longevity in a high-wear application 1095 may still be preferable.

For non-knife tools that require easy machining, W1 tool steel is a softer but tougher substitute for 1095. At lower hardnesses it machines very well, according to this overview of W1, making it suitable for applications like drill bits, taps, and reamers. However, it cannot reach the peak hardness of 1095 and has lower wear resistance.

No matter the application, when choosing a substitute for 1095 carbon steel the key is evaluating the needed properties. An alloy like O1 provides better corrosion resistance with similar hardness, 52100 raises toughness, and W1 makes the steel easier to machine. Consider the performance needs and operating environment to pick the best 1095 alternative.

Conclusion

In summary, 1095 carbon steel is an excellent option for tools and weapons that require good hardness and edge retention. Its high carbon content makes it easy to harden through heat treatment. While 1095 is a versatile steel, it does have some limitations in toughness and corrosion resistance.

When choosing an equivalent or alternative steel, consider your application and requirements. steels like 5160, 9260, and O1 have more chromium for enhanced toughness and rust resistance but may be more difficult to harden. For corrosion resistance, D2 steel and stainless steels like 440C are good options. Tool steels like A2 and S7 offer greater impact strength.

Test any potential 1095 carbon steel equivalents thoroughly before substituting them into production. While properties may look similar on paper, real-world performance can vary. With care and proper heat treatment, many steels can serve as suitable alternatives where 1095 is unavailable or unsuitable.