What Is A Low Fire Clay?

Low fire clays are a type of ceramic clay that is formulated to mature and vitrify at relatively low temperatures, typically between cone 04 (1945°F or 1063°C) and cone 2 (2165°F or 1185°C) [1]. They are characterized by their white or light color even when fired, smooth and buttery texture that is easy to work with, and low firing temperature requirements compared to stoneware and porcelain clays.

The key properties of low fire clays are their lower maturation temperature which allows firing in simple kilns or even primitive pit firing, smooth and plastic workability that makes shaping and sculpting easy, and light color results even when fired to maturity. These characteristics make low fire clays popular for handbuilding, sculpting, and modeling work where higher clay bodies like stoneware or porcelain would be more difficult to work with.

In contrast to low fire earthenware clays, high fire clays like stoneware and porcelain mature at much higher temperatures typically between cones 6-10 (2232°F-2345°F or 1222°C-1285°C). High fire clays can be harder to work with for handbuilding and sculpting due to their stiffer, less plastic nature. However, they result in harder, more durable finished ware. The higher firing temperatures also allow for wider glaze possibilities and can produce pottery with color and sheen finishes not possible in low fire.

Common Types of Low Fire Clays

Low fire clays refer to clays that mature and become ceramic between cone 06 and cone 3 (1800-2100°F / 982-1149°C). There are several common types of low fire clays:

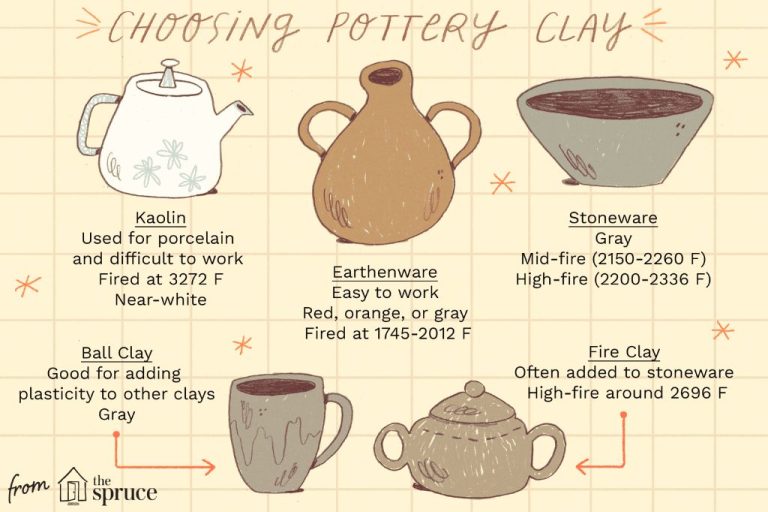

Earthenware clays – These natural clays are very plastic and smooth working. They fire to a variety of earthtone colors like red, brown, and buff.

Red firing clays – Clays like Redart have additives like iron oxide to produce bright red colors when fired, making them popular for pottery.

White firing clays – White firing earthenware clays are used to make white ware and porcelain-like bodies. These include clays like White Earthenware.

Ball clays – Ball clays are very plastic, high shrinkage clays that help improve workability and green strength in clay bodies. They fire to a creamy white color.

Kaolin clays – Kaolin clays are white firing clays that provide whiteness and plasticity to clay bodies, helping fusion at low temperatures. They are essential in porcelain clays.(1)

Some example text. According to Source 1, low fire clays are fired at temperatures between ____ and ____ degrees. The most common low fire temperature is around ____ degrees, which produces specific effects in the clay.

Firing Temperatures

Low fire clays are defined as those fired at relatively low temperatures, typically ranging from 1745-2120°F (950-1160°C). The most commonly used low fire temperature is around 1830°F (1000°C).

Firing at these lower temperatures means the clay does not vitrify and keeps an open, porous structure. The lower temperatures also prevent the clay from fusing strongly, so low fire pieces tend to be more fragile. However, firing at a lower temperature allows faster firing and cooling cycles. It also decreases the energy usage compared to higher fire clays. The lower temperatures lead to brighter glaze colors since less interaction occurs between the clay and glaze materials.

Working Properties

Low fire clays exhibit specific working properties that make them suitable for certain applications. Some key factors to consider are plasticity, dry strength, shrinkage and absorption. According to Keene High School, low fire clays tend to be more plastic and have lower dry strength compared to high fire clays. This makes them easier to work with and form into shapes.

Low fire clays also have higher shrinkage, typically between 8-12%. The increased shrinkage must be accounted for when designing pieces. However, it can help make complex shapes easier to execute. Finally, low fire clays have higher absorption, often 10-15% even when vitrified. The increased porosity makes them less suited for functional ware that will hold liquids. However, it provides an appealing tactile quality in sculpture and decorative pieces.

Overall, the working properties of low fire clays allow for great freedom and expression when forming pieces by hand or wheel. Their plasticity and shrinkage facilitate shaping, while the absorption lends visual interest. Understanding these key characteristics helps potters select the best clay for their needs.

Glazes for Low Fire Clays

There are many types of glazes suitable for low fire clays that work well at cone 06 firing temperatures. Some popular options include:

- Transparent glazes – These allow the natural color of the clay body to show through. They are available in gloss or satin finishes. (https://euclids.com/products/cone-6-transparent-glaze-5l-pail)

- Colored glazes – These come in a wide range of colors from bold primaries to soft pastels. Many contain no lead or other toxic materials.

- Matte glazes – These have a smooth, non-reflective surface. They are often used to achieve a “dry” look on pottery.

- Crawls and textures – These create interesting visual effects like cracking or peeling.

Glazes can be applied using dipping, pouring, brushing, or spraying methods. It’s important to follow the manufacturer’s instructions for application and firing. Special considerations for low fire glazes include:

- Applying in thinner coats since low fire glazes flux more readily.

- Testing compatibility if layering or mixing glazes.

- Avoiding overfiring, which can cause defects like pinholing.

- Allowing adequate airflow during firing to prevent bloating.

With proper application and firing, low fire glazes can produce gorgeous results on earthenware clays.

Firing Considerations

When firing low fire clays, it’s important to choose the right kiln and optimize the firing cycle. The most common kilns used are electric kilns, which allow precise control over temperature. Top-loading electric kilns like the Jen-Ken AF3P are well-suited for firing low fire ceramics.

Firing cycles for low fire clays typically range from cone 06 to cone 04. It’s important to use slow bisque firing cycles, ramping up at 100-150°F per hour. Fast firing can lead to defects like bloating, cracking, or scorching. The final glaze firing cycle should also be gradual, especially during the critical early stages of glaze melting.

Firing in oxidation is ideal for low fire clays to allow glazes to develop their full color and to avoid darkening the clay body. Reduction firing is not recommended as it can over-flux glazes. Common problems like pinholing, crazing, or shivering glazes can often be solved by adjusting the firing cycle or glaze recipe.

Uses of Low Fire Clays

Low fire clays are well-suited for certain types of ceramic pieces. Some common uses include:

Types of ceramic pieces well-suited to low fire

Low fire clays are often used for decorative and non-functional pieces like sculptures, tiles, and pottery. The porous nature and lower durability of low fire clays make them less ideal for heavy-use functional items. Low fire clays are better suited for: https://craftychica.com/2023/04/all-about-low-fire-ceramics/

- Sculptures

- Decorative tiles

- Pottery

- Wall hangings

Kitchenware

While low fire clays can technically be used for kitchenware like mugs, plates, and bowls, they require careful glazing to make them food-safe and water-tight. The porous nature of low fire clay makes kitchen items prone to staining and bacterial growth without a robust glaze. Low fire mugs and dishes are best used decoratively rather than functionally. https://thepotterywheel.com/low-fire-vs-high-fire-clay/

Garden pots

Outdoor garden pots are another common application for low fire clays. The natural look and porous nature of low fire clay allows excess water to seep out of soil, helping prevent root rot. Unglazed terra cotta pots made with low fire clay are inexpensive and provide ideal growing conditions for plants.

Decorative pieces

As a more delicate and porous clay body, low fire clays excel at decorative finishes. Vivid glazes, intricate detailing, and complex shapes can be achieved with low fire clays. The colors and surfaces possible make low fire clays ideal for purely decorative objects like figurines, wall art, candle holders, and vases.

Advantages of Low Fire Clays

There are several key advantages to using low fire clays over high fire alternatives:

Lower firing costs – Low fire clays reach maturity at lower temperatures, typically between cone 06 and cone 3 (1800-2200°F). This means they require less energy and fuel to fire, reducing overall firing costs (https://craftychica.com/2023/04/all-about-low-fire-ceramics/).

Faster production – The lower temperatures allow pieces to be fired more quickly through the entire firing schedule. This enables faster throughput and production (https://thepotterywheel.com/low-fire-vs-high-fire-clay/).

Wider range of colors – Low fire clays can produce brighter, more vibrant colors than high fire versions. The lower temperatures prevent the dulling or burning out of certain pigments.

Less prone to flaws – High fire clays go through more extreme temperature changes increasing the risks of flaws like cracking or warping. Low fire clays undergo less thermal stress resulting in fewer issues.

Disadvantages of Low Fire Clays

While low fire clays offer some benefits, they also come with some drawbacks compared to high fire clays. Some of the main disadvantages of low fire clays include:

Less durable – Pieces made from low fire clay tend to be more fragile and porous than those fired at higher temperatures. According to thepotterywheel.com, low fire earthenware clay will absorb water and is not as strong as stoneware or porcelain clays fired at higher temperatures.

Limited to smaller pieces – The porous nature and lower durability of low fire clays makes them less suitable for very large ceramic pieces. As noted on Ceramic Arts Daily, low fire clay has size limitations for functional pottery items.

Fewer firing options – Low fire clays must be fired at lower temperatures, limiting the firing methods and kilns that can be used. High fire clays are more versatile and can be fired using a variety of methods to higher temperatures.

Conclusion

In summary, low fire clays are pottery clays that mature and become vitrified at lower temperatures, typically under 2,200°F (1,204°C). The most common low fire clays are earthenware clays and terra cotta clays, which are useful for their warmth of color and easy working properties. Low fire clays require less energy to fire and are fired in shorter cycles, making them popular for beginners, hobbyists, and production potters. They can be decorated with low fire glazes and underglazes to create finished ware with vibrant colors and designs. The porosity of low fire clays allows use for planters and other decorative objects. While low fire clays do not become as durable as high fire clays, their accessibility and wide range of applications make them a staple clay body for many ceramic artists and potters.

In conclusion, low fire clays offer versatility, cost-effectiveness, and approachability in ceramic production and design. Their user-friendly properties continue to make them a popular choice for potters and artists who appreciate their various advantages and creative possibilities. When used thoughtfully, low fire clays allow makers of all levels to produce beautiful and functional ceramic wares.