What Is Ceramics Class?

What is Ceramics?

Ceramics are inorganic, non-metallic materials made from clay and crystalline minerals that are shaped and then hardened by heating at high temperatures. The word “ceramic” comes from the Greek word keramos, meaning “potter’s clay” (Cambridge Dictionary). Ceramics are compounds formed between metallic and non-metallic elements. The most common ceramics are made of clay, which is a crystalline form of hydrated aluminum silicate.

The process of creating ceramics typically involves shaping the clay, decorating or glazing the surface, and firing the clay in a high temperature kiln or oven. Firing permanently transforms the clay into a durable, solid material through sintering (particles partially melting and fusing together) and through chemical reactions that take place between minerals in the clay and any glazes applied to the surface. Common firing temperatures range from 1,652°F to 2,460°F (900°C to 1,350°C). The higher the firing temperature, the more dense and durable the finished ceramic becomes.

There are many different types of ceramic materials, including earthenware, stoneware, porcelain, and technical ceramics. Ceramics are valued for their mechanical properties such as high strength and hardness, thermal and chemical stability, electrical properties, and biocompatibility. As a result, ceramics have many diverse applications including pottery, tiles, sculptures, electronics, glass, refractories, and biomaterials.

History of Ceramic Arts

The history of ceramics dates back thousands of years. Archaeological evidence suggests that primitive pottery vessels were being made in East Asia and the Near East as early as 20,000-10,000 BCE, during the late Palaeolithic period.

The oldest known ceramic artifact is the Venus of Dolní Věstonice, a ceramic figurine dating back to 29,000–25,000 BCE found in the Czech Republic.[1] In Japan, ceramics have been dated to the 11th millennium BCE.[2]

The invention of the potter’s wheel in Mesopotamia sometime between 6,000 and 4,000 BCE revolutionized pottery production.[2] This enabled the creation of symmetric pottery forms and contributed to the expansion of pottery across the globe.

Key developments and styles throughout history include:

- Ancient Greek Pottery – Distinctive black and red figure pottery.

- Tang Dynasty Pottery – Known for graceful forms and innovative glazes.

- Majolica Pottery – Colorful tin-glazed earthenware from the Italian Renaissance.

- Delftware – Elegant blue and white pottery originating in the Netherlands.

- Porcelain – Thin, translucent china perfected in China.

Over thousands of years, ceramic art and pottery has evolved with each culture, era and geographic region developing their own unique styles and innovations.

Types of Ceramic Arts

There are several main types of ceramic arts including pottery, sculpture, tiles, and glasswork.

Pottery refers to functional or decorative vessels made out of clay and fired in a kiln. Some common types of pottery are earthenware, stoneware, and porcelain. Pottery can be hand built or thrown on a potter’s wheel.

Ceramic sculpture involves creating artwork out of clay that is not functional but rather purely decorative or artistic. Sculptures can be realistic representations of people, animals, or objects, or they can be abstract shapes and forms.

Ceramic tiles have been used to decorate floors, walls, countertops, and other surfaces for thousands of years. Tiles can be painted, glazed, or etched with decorative designs. Mosaic murals and other tile artwork are also common forms of ceramic tiling.

Glasswork is a type of ceramic art that involves heating silica sand and other additives into a molten state and then cooling the mixture into glass. Stained glass, blown glass vases or sculptures, and fused glass jewelry are some examples of artistic glasswork.

For more information on types of ceramic arts, see this overview.

Ceramics Class Structure

A typical ceramics class focuses on teaching various handbuilding and wheel throwing techniques. Students will learn how to work with clay and create both functional pottery and sculptural pieces.

In the beginning of class, the instructor often starts with demonstrations of new techniques as well as reviews of previously learned skills. Common handbuilding techniques that may be covered include pinch pots, coil building, and slab construction. For wheel throwing, students will learn wedging and centering clay, opening a cylinder, pulling a wall, and finishing techniques.

After demonstrations, the majority of class time is devoted to students independently working on their own projects while receiving individual guidance from the instructor. While working, students develop their skills through repetition and experimentation with the techniques.

Long term ceramics projects often involve creating a series of themed works demonstrating mastery of specific skills. For example, students may be tasked with producing a set of vessels from the wheel showing their proficiency in that technique.

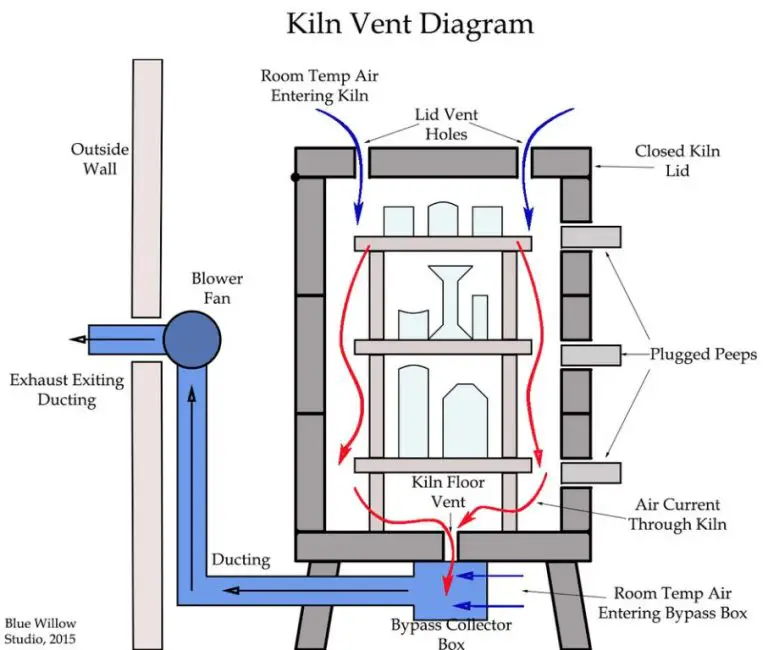

Once pieces are built, students learn processes for decoration and finishing like glazing and firing. The works are loaded into kilns which heat to high temperatures to permanently harden the clay. Finished pieces are often displayed in a final classroom exhibition.

A ceramics class teaches not only artistic skills but also perseverance, creativity, and problem solving. With practice over the course of the term, students gain expertise and satisfaction in working with this versatile medium.

Clay Materials

There are several types of clay used in ceramics class for handbuilding, wheel throwing, and sculpting. The main types include earthenware, stoneware, and porcelain.

Earthenware clay contains a high percentage of iron and other minerals. It can be found in a wide range of colors including red, brown, and terracotta. Earthenware fires at lower temperatures, between 1745-2150°F. It’s easy to work with but porous. Types of earthenware clay include red clay, buff clay, and terracotta clay. (Source)

Stoneware clays are denser, with fewer impurities than earthenware clay. They fire at a higher temperature range, between 2160-2380°F. Stoneware clay can be used to create items for functional purposes that hold water. Popular types of stoneware clay are ball clay, fire clay, and stoneware clay.

Porcelain clays have very low iron content, giving them a white color when fired. Porcelain is the strongest ceramic material, dense and non-porous. It fires at an extremely high range 2390-2485°F. Porcelain clay is harder to work with but can create delicate, translucent pieces.

Handbuilding Techniques

There are three main handbuilding techniques used in ceramics – pinch, coil, and slab construction. Handbuilding involves shaping clay by hand without the use of a pottery wheel. It allows for more organic, sculptural forms that may be difficult to create on a wheel.

Pinch pots are made by pinching and pulling the clay to form simple shapes like bowls or vases. This is one of the most basic handbuilding techniques and does not require any tools. Pinching allows the clay to slowly take shape through the fingertips.[1]

Coil building involves rolling out and stacking ropes or coils of clay on top of each other to build up a form. Coils can be arranged vertically or horizontally. The coils are blended together using slurry or scoring and slipping to fuse them into one solid piece. Coiling enables clay artists to make larger and more intricate handbuilt forms.

Slab construction refers to building with flat, rolled out sheets or slabs of clay. The slabs can be cut into shapes and assembled into a sculpture or vessel. Soft slabs are flexible and floppy. Hard slabs have a stiffer, leather-hard consistency. Slab pieces can be constructed using score and slip, clay slurry, or mechanical fasteners.[2]

Wheel Throwing

Wheel throwing is a process of shaping clay using a pottery wheel. The clay is centered on the wheel head and rotated rapidly as the potter uses their hands, tools, and water to shape the clay into various forms.

To center the clay, a clay block is wedged and formed into a ball or cone shape. Using both hands, the clay is pressed onto the wheel head and compressed into a dome shape. Applying pressure at the base while allowing the top to spin off creates a centered cone shape.

Once centered, the potter opens up the form by pushing into the sides of the clay with thumbs, while maintaining an even wall thickness. Cylindrical, bowl, and vase shapes can be thrown by manipulating the clay with tools and hands. Complex shapes utilize techniques like pulling up the walls, altering the rim, and adding decorative elements.

Throwing takes practice to control the clay and create uniform pieces. Factors like wheel speed, moisture content, and clay consistency impact the process. With experience, potters can throw a wide variety of functional pieces with thin walls and refined forms.

Decorating and Glazing

Glazes, slips, and stains are used to enhance the look of ceramic pieces both functionally and aesthetically. Glazes provide a protective and decorative glass-like coating on the surface of bisqueware that has been fired in a kiln. Glazes are made from a mixture of silica, fluxes, and other oxides that melt and fuse to the clay surface when fired to a high temperature. There are many types of glazes to choose from like glossy glazes, matte glazes, transparent and opaque glazes in infinite colors and textures. Glazes can be brushed on, poured, dipped, or sprayed onto bisqueware. Popular glazing techniques include dipping, layering, dripping, and sponging to create interesting effects. Underglazes are also used before glazing to add color and patterns which get sealed in under a clear glaze during firing.

Slips are made from clay, water, and fillers applied to greenware or bisqueware before firing. Terra sigillatas are a type of refined slip made from extremely fine clay particles that burnish and polish the surface giving an attractive sheen. Stains contain ceramic stains suspended in water and can be painted directly onto bisqueware and incorporate vibrant colors. Waxes and resists are also used to create patterns by blocking areas from receiving glaze during dipping or spraying. There are many ways to creatively decorate ceramic pieces like painting, sponging, incising, carving, stenciling, stamping, and more to add beautiful and unique touches. With the right glazing and decorating techniques, ceramics can be transformed into incredible works of art.

Firing and Kilns

Firing is one of the most important steps in ceramics, as it transforms soft clay into a hardened ceramic material. There are several types of firings in ceramics:

Bisque Firing: The first firing done on greenware or unfired clay. Bisque firing heats the clay to around 1200-1800°F to harden it and prepare it for glazing. Bisque firing is done in a bisque kiln or regular kiln. This step removes any water from the clay and makes the piece less porous. According to Diamond Core Tools, bisque firing usually takes 4-12 hours depending on the size of the kiln and pieces.

Glaze Firing: The second firing done on bisque ware that has been glazed. Glaze firing melts the glaze onto the surface of the clay and can reach temperatures between 1800-2300°F. Glaze firing uses a regular ceramic kiln and typically takes 4-10 hours.

Raku Firing: A type of low-fire glaze firing that is done quickly, around 1500-1800°F. Raku firing involves removing pottery from the kiln while red hot and placing it into containers with combustible materials to create unique crackled effects. The quick cooling gives distinct raku finishes.

Pit Firing: One of the oldest firing methods that does not require a modern kiln. Pit firing involves digging a pit, building a fire in it using various fuels like wood or sawdust, and covering the pottery with combustibles. Firing temps can reach over 2000°F. Pit firing produces beautiful smoky effects but can be more unpredictable.

There are various types of ceramic kilns used in firing:

- Electric kilns

- Gas kilns

- Wood-fired kilns

- Raku kilns

- Pit kilns

Choosing a kiln and firing technique depends on the type of clay, glazes, fuels available, and the desired effects for the finished ceramic pieces.

Safety

Working with ceramic materials and equipment requires following proper safety precautions. Ceramics studios contain many potential hazards including dust, fumes, heavy equipment, and sharp tools. Students should be aware of these dangers and adhere to studio rules and guidelines.

Some key safety practices in the ceramics studio include:

- Wearing proper protective equipment like dust masks, respirators, gloves, and safety glasses

- Keeping the studio clean and free of slip/clay residue on floors

- Using tools, kilns, and equipment properly after receiving instruction

- Following safe lifting procedures when handling heavy bags of clay

- Storing hazardous chemicals correctly and using proper ventilation

- Reporting any injuries or safety issues immediately

- Keeping studio doors closed and minimizing outside visitors

- No food or drink allowed in the studio to prevent contamination

Adhering to ceramics studio rules and best practices is crucial for staying safe and healthy. Always be mindful when working with ceramic materials, ask questions if unsure, and notify the instructor about any concerns.

Sources:

https://ceramic.school/pottery-studio-safety/

https://leecollegelibrary.com/ceramics/safety/safety_print.html