What Is Glazed Terracotta Made Of?

What is Terracotta?

Terracotta, from the Italian word terra cotta meaning “baked earth,” is a type of clay-based ceramic made from terracotta clay that has been fired at high temperatures in a kiln. The history of terracotta dates back over 4000 years to early human civilizations.

Terracotta clay is an orange-red natural clay containing iron oxide that gives it its distinct reddish color. It’s made from volcanic ash and clay minerals such as kaolinite. Terracotta clay can be found in many regions around the world, with some of the largest deposits located in Italy and Spain.

Terracotta is known for being sturdy yet porous and lightweight with earthy colors. It has been used throughout history for sculpture, pottery, roof tiles, bricks, and other decorative and functional items. When fired at high temperatures between 1000-1100°C, the clay becomes ceramic, making it durable, water-resistant, and able to withstand weathering.

Common uses of terracotta include flower pots, bakeware, garden decor, architectural elements, and more. Its properties of breathability and water absorption make it useful for regulating moisture in items like planters. Terracotta’s natural rustic beauty has also made it popular for decorative crafts, art, and ornamentation.

Terracotta Clay Composition

Terracotta is made from natural clay which consists primarily of hydrated aluminosilicates with variable amounts of iron oxide, magnesium carbonate, and calcium carbonate. The most common clays used in creating terracotta are red and brown firing clays which contain large amounts of iron oxide (at least 15-20%).

Typical clay compositions for terracotta production contain around 60-80% clay minerals such as kaolinite, illite, and montmorillonite. Quartz or silica make up 10-30% of the raw material, with smaller amounts of feldspar, carbonates, iron oxides, and other impurities making up the remainder.

The exact ratios of the ingredients vary, but a typical clay body for terracotta may contain 60-70% clay, 15-25% quartz, 5-10% feldspar, 2-5% iron oxide, and 1-3% calcium carbonate. The high iron oxide content in the clay gives terracotta its distinctive red-orange color when fired.

Some key characteristics like porosity, strength, color, and firing behavior are controlled by the mineralogical and chemical composition of the raw clay. The plasticity for modeling and shaping the clay pieces also depends significantly on the clay particle size distribution and composition.

Sources:

Decorative Terracotta Planter

Making Terracotta

The process of making terracotta begins with gathering the raw materials. The main ingredient is clay, which comes from mineral deposits in the earth. Terracotta clays contain varying proportions of silica, alumina, lime, iron oxide, magnesia, and other minerals. The different clay compositions result in different properties when fired.

After extracting the clay, it is refined to remove impurities. Next, the clay is mixed with water to reach an ideal consistency for molding and shaping. The clay mixture is wedged or kneaded to remove air pockets and achieve an even moisture content. Manufacturers may also add colorants and strengtheners to the clay at this stage.

Once the clay is prepared, it is molded or shaped into the desired forms. Potters may shape terracotta by hand or use molds. Another technique is throwing on a potter’s wheel. Terracotta can be worked into all kinds of shapes including pots, tiles, and figurines.

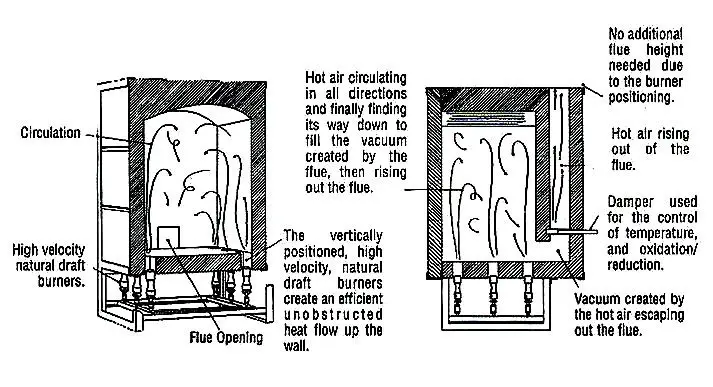

After molding, the clay forms undergo a slow drying process. As the water evaporates, the terracotta hardens until firm enough for firing. Drying typically takes several weeks depending on the size and shape of the clay pieces. Kilns allow greater control over temperature and humidity during drying.

For more details on the terracotta making process, check out this guide: https://martinlprrr.glifeblog.com/23806925/unveiling-the-artistry-how-terracotta-is-made-a-comprehensive-guide

Glazing Terracotta

Glazing is a process of applying an impervious and decorative coating to the surface of terracotta clay. The glaze creates a glass-like finish when fired at high temperatures in a kiln. There are several steps involved in glazing terracotta:

The main ingredients in ceramic glazes are silica, fluxes, and stabilizers. Silica, in the form of fine quartz or sand, forms the glassy phase of the glaze. Common fluxes used are alkali metals like sodium and potassium which lower the melting point of the silica. Stabilizers such as calcium, magnesium, and aluminum oxides help regulate the glaze formula and prevent defects like pinholes, cracks or crazing. Some common glaze ingredients are feldspar, clay, borax, zinc oxide, and colorants like metal oxides.

There are different techniques for applying glazes on terracotta ware. Glazes can be applied by dipping, pouring, brushing or spraying. The bisque-fired clay body needs to be cleaned thoroughly before glazing. 2-3 coats are typically applied, allowing each coat to dry before applying the next. The glazed pieces are fired at temperatures between 2200°F to 2300°F to mature the glaze.

Glazes can create a wide range of effects and finishes. Common types of glazes used on terracotta are glossy, matte, crystalline, satin, crackled and colored glazes. Special techniques like layering, trailing, brushwork and resist methods produce distinctive decorative effects.

For more on glazing ingredients and techniques, check out these resources:

https://www.thecrucible.org/guides/ceramics/how-to-glaze/

https://www.soulceramics.com/pages/glazing-ceramics-basics

Glazed Terracotta Properties

Glazed terracotta has several useful properties that make it a popular material for construction, decoration, and more. Some of the key properties of glazed terracotta include:

Improved strength – The glazing process strengthens the underlying terracotta clay body, making it more durable and resistant to damage. Glazes seal the surface and prevent moisture from penetrating the porous clay body. This protection results in improved strength and longevity.

Water resistance – Terracotta on its own is prone to water absorption. The impervious glaze layer makes glazed terracotta water resistant by blocking moisture penetration into the clay body. This resistance to water allows glazed terracotta to be used outdoors and in wet environments.

Decorative effects – Glazes come in a vast array of colors, textures, and finishes. They can be glossy, matte, metallic, speckled, crackled, and more. Glazing transforms basic terracotta into a visually striking decorative material. The colors and surfaces of glazed terracotta add aesthetic appeal in architecture, pottery, sculpture, and other applications.

These properties have made glazed terracotta a popular choice for building materials, architectural decoration, tableware, garden pots, and artworks throughout history up to the present day. The glazing process enhances both the durability and visual appeal of terracotta clay.

Uses of Glazed Terracotta

Glazed terracotta has been utilized for a wide variety of purposes throughout history thanks to its durability, design versatility, and decorative aesthetic. Some of the most common uses of glazed terracotta include:

Architectural Decoration

Glazed terracotta is an ideal material for architectural decoration and design elements. Its ability to be molded into various shapes and patterns allows architects and designers to create custom decorative features like tiles, reliefs, panels, and architectural terra cotta on building exteriors and interiors. The glaze provides extra durability and adds visual interest with colors and textures.

According to https://www.toolify.ai/gpts/discover-the-amazing-world-of-glazed-terracotta-365074, glazed terracotta blocks can be shaped into arched windows, cornices, columns, and other unique architectural elements.

Garden Pots

The durability and weather resistance of glazed terracotta has made it a popular choice for flower pots and other garden containers for centuries. Glazes allow the pots to come in endless colors and designs to complement different garden aesthetics. The porosity of terracotta also provides good drainage and aeration for plant roots.

Tableware

Glazed terracotta tableware and pottery such as plates, bowls, mugs, and vases have been produced for thousands of years. The glaze makes them non-porous so they can hold liquids without leaking. Decorative patterns and brilliant glaze colors make glazed terracotta tableware aesthetically pleasing in both traditional and modern decor.

Glazed Terracotta Through History

Glazed terracotta has been used as an architectural and decorative material for thousands of years. Some of the earliest known examples come from ancient Egypt and Greece. Terracotta tiles and decorations with colored glazes were used to adorn temples, palaces and other important buildings.

In medieval Europe, glazed terracotta grew in popularity for use on churches and cathedrals. The vivid colors and intricate designs allowed artisans to add ornate decorative elements to religious structures. Italian craftsmen like the della Robbia family became well known for their glazed terracotta reliefs and sculptural works during the Renaissance.

By the 19th century, architectural terracotta really came into prominence. Buildings across Europe and the United States began to incorporate terracotta decorative elements and facades. The material was appreciated for its versatile colors, durability and flame-retardant qualities. Major buildings like the Natural History Museum in London featured extensive architectural terracotta. (Boyd, 2020)

So while the basic material has remained the same, glazed terracotta has been an important architectural material for millennia. The vibrant colors and sculptural possibilities have made it a valued building material across various cultures and eras.

Modern Glazed Terracotta

Contemporary artists and architects have continued to push the boundaries of glazed terracotta. While the material has existed for centuries, modern techniques and designs have breathed new life into this classic medium.

Artists like Pablo Picasso, Joan Miró and Alexander Calder made breakthrough sculptural pieces in glazed terracotta. Their innovative techniques and bold designs ushered in new ways to utilize the material beyond traditional pottery and tiles. Many modern artists now use glazed terracotta for its versatility and bright colors. Some employ experimental glazing methods or choose alternative firing methods to achieve unique visual effects.

Glazed terracotta has also become a popular architectural material in the 20th and 21st centuries. Iconic modernist architects like Frank Lloyd Wright, Louis Kahn, and Eero Saarinen made striking use of vibrant glazed terracotta on many famous buildings. The strong, durable nature of glazed terracotta makes it ideal for both exteriors and interiors of modern structures. Glazed terracotta panels can provide visual interest and color while also being a protective facade material. Innovative techniques like load-bearing glazed blocks and large custom-made tiles reveal the material’s continued versatility. Revered architects continue to specify glazed terracotta as a way to add artistry and permanence to modern architectural designs.

Notable Examples

Glazed terracotta has been used to create many famous buildings, monuments, and ceramic pieces throughout history. Some of the most well-known uses of glazed terracotta include:

The Woolworth Building in New York City, an early skyscraper built in 1912, features ornate glazed terracotta on its facade. Architect Cass Gilbert chose glazed terracotta for its fire-resistant properties and ability to be sculpted into decorative details.

The Wrigley Building in Chicago uses glazed terracotta for its bright white facade and intricate neo-Gothic ornamentation. The terra-cotta provides a lightweight, durable surface that allows for intricate carvings.

The work of the Della Robbia family in 15th century Florence included intricate glazed terracotta friezes, reliefs, and sculptures. Luca della Robbia developed a glazing technique that allowed for vibrant blue, green, yellow, and white glazes on terracotta.

Some famous modern ceramists working in glazed terracotta include Peter Voulkos, Beatrice Wood, and Robert Arneson. Their innovative glazing techniques and sculptural works expanded the creative possibilities of the medium.

Future of Glazed Terracotta

Glazed terracotta has been used for centuries, but there are still new innovations and applications being discovered. Some areas of development for the future of glazed terracotta include:

Potential New Applications: Glazed terracotta is being tested for new uses such as countertops, floor and wall tiles, and outdoor landscaping features. Its durability and vibrant colors make it an attractive option. New digital printing techniques allow more intricate designs and patterns to be applied to glazed terracotta as well.(1)

Sustainability: As a sustainable and recyclable material, efforts are being made to improve the energy efficiency of firing glazed terracotta. Some manufacturers are also using recycled clay materials. Glazed terracotta can last hundreds of years, making it a very green building material.

Preserving Tradition: Glazed terracotta production is still thriving in historic centers like Portugal, Italy, and China. Both artisans and large manufacturers are finding new global markets while preserving this traditional craft. New generations are also being trained to keep the techniques alive.

With its versatility, durability, and aesthetic appeal, glazed terracotta will continue adapting to fill both traditional and innovative new roles well into the future.