What Is Mason Stains?

What are Mason stains?

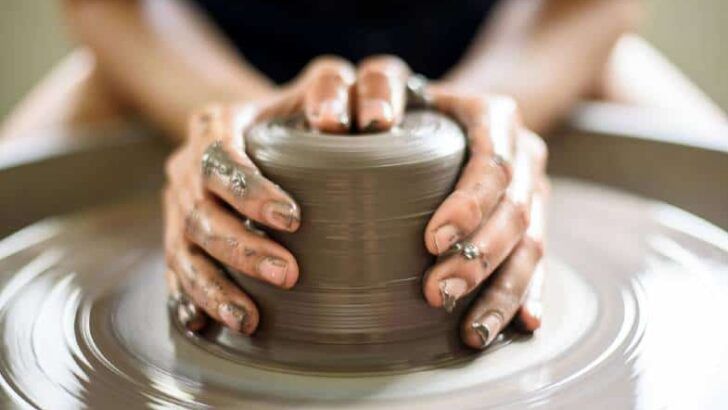

Mason stains are colored stains used in pottery and ceramics. They are made from metal oxides that produce vibrant colors when fired at high temperatures. The name comes from their inventor, Dr. S.S. Mason, who first formulated these stains in the 1920s.

According to Brackers, Mason stains are “oxides or combinations of oxides and opacifiers that have been blended and fritted* to ensure color consistency from batch to batch” (https://www.brackers.com/materials-monday-marvelous-mason-stains/). The fritting process involves heating the raw materials to a high temperature to fuse them together.

Sheffield Pottery describes Mason stains as “inorganic, leach-proof ceramic stains that can be used on any clay body” (https://www.sheffield-pottery.com/Mason-Stains-s/8.htm). The stains are lead-free and food safe.

Mason stains are different from glazes in that they maintain their color integrity at high temperatures. They produce consistent, vibrant colors on clay bodies and are useful for stained glass effects.

Characteristics of Mason Stains

Mason stains are ceramic stains made from metal oxides that produce a wide variety of colors when fired on ceramic surfaces like clay, porcelain, and stoneware. The key characteristics of Mason stains include:

Color: Mason stains are known for producing vibrant, saturated colors ranging from earth tones like brown, tan, and rust to primaries like blue, red, yellow and more. According to Sheffield Pottery, there are over 80 brilliant colors to choose from.

Texture: When applied to moist clay or glazes, Mason stains can produce color effects that are smooth and even or textured and mottled depending on application technique. As noted by Bailey Pottery, stains can create flowing color contrasts or intricate patterns.

Location: Mason stains are commonly observed on the exterior surfaces of bricks, though they can also occur on interior surfaces. Exterior staining is often more prevalent as bricks are exposed to weathering elements.

According to Sheffield Pottery, the color effects of Mason stains are influenced by factors like clay body, glaze fit, and firing temperature which affects individual results.

Causes of Mason Stains

Mason stains are primarily caused by metal oxides that are present in clay bodies and glazes. The most common metal oxides that lead to mason stains include iron, manganese, copper, cobalt, and chromium. When fired in a kiln, these metal oxides can form colors on the surface of pottery pieces if they are not properly balanced in the clay body or glaze recipe (see: Mason Stains Frequently Asked Questions).

Another common cause of mason stains is pollution in the kiln environment. Sources of pollution include dust, kiln wash, silica flakes, and other debris that can get trapped in the kiln. As the kiln fires, this pollution can deposit on pottery surfaces and create stains. Careful kiln maintenance and protection of ware during firing can help prevent stains from pollution (Frequently Asked Questions).

Finally, direct contact between pottery and materials like concrete, mortar, or brick during the firing process is another potential cause of mason stains. Glaze or clay can react with alkalis and minerals from these materials, leading to discoloration. Keeping pottery elevated and free of contact with foreign materials in the kiln is important to avoid transfer stains.

Types of Mason stains

There are three common types of Mason stains, each including different metal oxides that produce certain colors and effects:

- Efflorescence stains contain materials like barium carbonate and calcium sulfate that create whites and light pastel colors.

- Vanadium stains provide strong colors ranging from bright yellow to deep blue-green.

- Manganese stains produce earthy tones like brown, purple and black.

The specific metal oxide used in a Mason stain determines the color it produces. Combining certain stains creates blended hues.

For example, mixing a vanadium yellow with a manganese brown makes an orange Mason stain. Ceramic artists can create custom color palettes by experimenting with mixing different stain types.

Preventing Mason stains

There are a few key ways to help prevent Mason stains from forming on ceramic wares:

Proper storage – Mason stains should be stored in air-tight containers when not in use. Exposure to moisture and humidity can cause the stains to clump or grow mold. Storing stains in a cool, dry area will help prolong their shelf life. According to one source, “Keep stains in air-tight jars and never return unused stain to the original container.” (1)

Protective coatings – Applying a protective coating or sealer to finished ceramic pieces can create a barrier to help prevent Mason stains from forming. Options include using a food-safe sealant, a washable topcoat glaze firing, or a ceramic wax coating. Test compatibility with the glaze first.

Firing temperature – Firing ceramics to the optimal temperature for the clay body and glaze can help vitrify the material properly and reduce stain absorption. Underfired pieces tend to be more porous. Always test fire individual glaze and clay formulations.

Removing Mason stains

There are a few methods for removing Mason stains from surfaces like pottery, porcelain, glass, and other ceramics.

One of the most effective cleaning methods is to use a bleach solution. Make a diluted bleach solution with 1 part bleach and 9 parts water. Apply the solution to the stained area with a soft cloth or sponge. Let it sit for 5-10 minutes, then rinse thoroughly with clean water. The bleach will help break down and lift the stained material. Be careful not to leave the bleach on too long, as it can damage or discolor the surface. Test first in an inconspicuous area.

Another option is to use a ceramic stain remover or cleaner specifically designed for porcelain and pottery. Products like Cerama Bryte or Dirtex can help lift stubborn stains without damaging the finish. Follow the product instructions closely.

For tough stains, a poultice may be required. A poultice is a paste made with an absorbent material like talc or clay, mixed with a solvent like acetone. Apply the poultice paste directly to the stain, cover with plastic wrap, and let sit for 24 hours before scrubbing clean. This draws out deeply set stains.

Always test stain removers in an inconspicuous spot first to ensure they don’t damage the ceramic piece. Avoid abrasive scouring pads during cleaning, as they can scratch the glazed surface. With careful, gentle cleaning, Mason stains can often be removed from ceramics without damage.

Cost of Mason Stain Removal

The cost of removing Mason stains can vary greatly depending on whether you hire a professional or tackle the job yourself. Here are some key factors that affect the cost:

Hiring a professional to remove Mason stains typically costs $200-300 on average. The price can go up depending on the severity of the stains, how porous the surface is, and the size of the area being treated. Professionals have access to commercial-grade cleaners and tools that make stain removal more effective.

Doing it yourself will be cheaper in terms of supplies, costing $30-50 for most DIY stain removal kits. However, DIY does require more physical effort, and there is a greater risk of damaging the surface if not done properly. Stubborn stains may also require multiple treatments, adding more time and material costs.

The composition of the stained material also impacts costs. More porous surfaces like concrete, grout, and natural stone will drive prices up compared to smoother materials. Older or deeper set stains that have soaked into the material take more work to lift.

When staining affects a large surface area, economy of scale comes into play. Professionals charge per project rather than per square foot, so bigger jobs are relatively more affordable. DIY costs remain proportional to the size of the area.

To save money, first try DIY methods on more manageable stains. Call in a professional if stains cover expansive areas or penetrate deep into porous surfaces. Their expertise and equipment can eliminate stains more efficiently.

When to call a professional

For severely stained or heritage buildings, it is best to call in a professional masonry cleaning company. Improper cleaning methods can permanently damage the masonry and even increase staining. According to this Reddit post, abrasive cleaning like sandblasting can drive the stain deeper into the masonry. Professionals have access to specialized equipment and chemicals, as well as the expertise to determine the appropriate methods for your building’s materials and stains.

Heritage buildings require extra care, as the masonry is often more porous and delicate. Harsh chemicals or high-pressure washing could erode detailing or patina that contributes to the building’s character. Professionals familiar with heritage buildings will use gentler techniques like poulticing or chemical cleaners designed for sensitive masonry. Their experience preserving historical buildings makes them well-equipped to remove stains without damage.

For severely stained or heritage buildings,Calling in the experts is the safest way to thoroughly clean staining while protecting the integrity of the masonry. Their knowledge and specialized techniques justify the higher cost for irreplaceable buildings.

Mason Stain Alternatives

There are a few alternatives to using mason stains to change the appearance of masonry surfaces like brick, concrete, and stone:

Stained concrete is a popular alternative. Concrete staining uses chemical stains to penetrate into the concrete and produce long-lasting color effects. The stain reacts with the lime in the concrete to create variegated, mottled coloring. Stained concrete has a very natural look compared to painted concrete. It also lasts much longer than paints or coatings on concrete (Source).

Painting brick is another option instead of staining it. Paint adheres to the brick surface to cover it with an opaque coat of color. Paint holds well when proper preparation and primer is used. However, it does not allow the brick to breathe and requires reapplication every 3-5 years as it fades and peels (Source).

Mason stains FAQs

Some of the most frequently asked questions about Mason stains include:

What are the most versatile Mason stains?

According to Mason Color’s Reference Guide, their Cobalt Blue, Rutile Blue, and Black stains can be used on multiple clays and at various temperatures to achieve a wide range of blue and black hues.

How do I get brighter pinks and reds?

As explained on Sheffield Pottery’s FAQ page, adding 1-3% tin oxide to your clay body can help produce brighter pinks and reds with Mason stains.

Can Mason stains be mixed together?

Yes, Mason stains can be mixed to create custom colors according to Mason Color’s FAQ, but some stain combinations may be incompatible, so testing is recommended.

Are Mason stains safe to use?

When used properly, Mason stains are generally considered safe, though some contain heavy metals like cobalt or chromium, so precautions like gloves and dust masks are recommended.