What Is Mold Soap?

Mold soap refers to any type of soap that is created using a mold. Molds allow soap makers to create decorative soaps in a variety of shapes and sizes. The history of mold soap can be traced back thousands of years. Evidence shows that ancient civilizations like the Babylonians, Mesopotamians, and Egyptians were making soap in molds as early as 2800 BC (Soap History).

The basic process for making mold soap involves mixing fats (like olive oil or animal fats) with an alkali, like lye. The chemical reaction between the fat and lye produces glycerin and soap. After tracing occurs, when the soap reaches the proper thickness, it can be poured into shaped molds. The soap hardens and cures in the mold for 1-6 weeks before being removed and used. Mold soaps allow creative flexibility in soap making.

What is Mold?

Mold is a type of fungus that grows in damp and humid environments. It reproduces by releasing tiny spores that float through the air. When the spores land on a wet surface, they can begin growing new mold colonies. There are thousands of species of mold, but some of the most common household molds include:

Black mold (Stachybotrys chartarum) – a greenish-black mold that grows on materials with high cellulose content like drywall, carpet, and wood. It produces mycotoxins that can cause respiratory issues.

Cladosporium – This olive-green or black mold is one of the most common found indoors. It grows on fabrics, wood, food, and other surfaces.

Penicillium – Often found indoors on wallpaper, carpet, mattress dust, and in HVAC systems. Produces blue, green, or gray colonies. Some species produce mycotoxins.

Alternaria – A plant pathogen that can also be found in homes. It appears as dark green to black colonies and can cause allergies and asthma flare-ups.

Aspergillus – Various species of Aspergillus grow on building materials, household dust, foods and grains. It produces grayish-yellow or tan colonies. A. fumigatus is associated with lung infections if inhaled.

Mold grows easily in homes, especially if there has been recent water damage from flooding, plumbing leaks, roof leaks, or humidity buildup. Keeping surfaces clean and dry helps prevent mold growth. Identifying and eliminating moisture sources is key to mold remediation in the home.

Mold Soap Ingredients

Mold soaps are made from a variety of oils that contribute to the qualities of the final bar. Common oils used include:

- Olive oil – A moisturizing oil that produces a mild, gentle soap.

- Coconut oil – Produces fluffy lather and hardness.

- Palm oil – Hardens and stabilizes the soap bar.

- Shea butter – A luxurious, moisturizing ingredient.

Scent ingredients like essential oils and fragrance oils are also added to mold soaps. Popular scents include lavender, lemon, rose, peppermint and more. The scents are added at the end of the soap making process.

Colorants are also commonly used in mold soaps to produce beautiful colored designs. Options include:

- Micas – Finely milled mineral powders.

- Clays – Naturally colored cosmetic clays.

- Pigments – Vibrant soap colorants.

By carefully selecting the oils, scents and colors, a wide variety of mold soaps can be created.

How Mold Soap is Made

The soap making process with molds begins by pouring the soap mixture into the mold. It’s important to pour the soap slowly and steadily to prevent air bubbles from forming. Once the mold is filled, it should be gently tapped on the counter to release any trapped air bubbles. Some soap makers also use a small burst of air from a straw to pop bubbles on the surface.

After pouring, the filled soap molds need time to setup and harden. This is known as the unmolding process. The length of cure time varies based on factors like the soap recipe, humidity, and temperature. Many mold soaps require 24-48 hours before they can be safely removed from the mold. Impatience during the unmolding process can lead to misshapen or cracked soaps.

Once unmolded, the soaps still require additional curing time to reach their full hardness and mildness. This curing period typically takes 4-6 weeks. During this time, excess moisture evaporates from the bars and the soap becomes firmer as saponification completes. Proper curing is vital for mold soaps to achieve an optimal appearance and skin-friendly pH level. Rushing this curing period can lead to sticky, smelly soap that irritates skin.

For detailed tips on filling and unmolding soap molds, check out this helpful guide: https://www.pinterest.com/tonysanta/homemade/

Benefits of Mold Soaps

![]()

Mold soaps provide several key benefits compared to simply pouring soap into a basic slab mold. Some of the main advantages of using creative molds include:

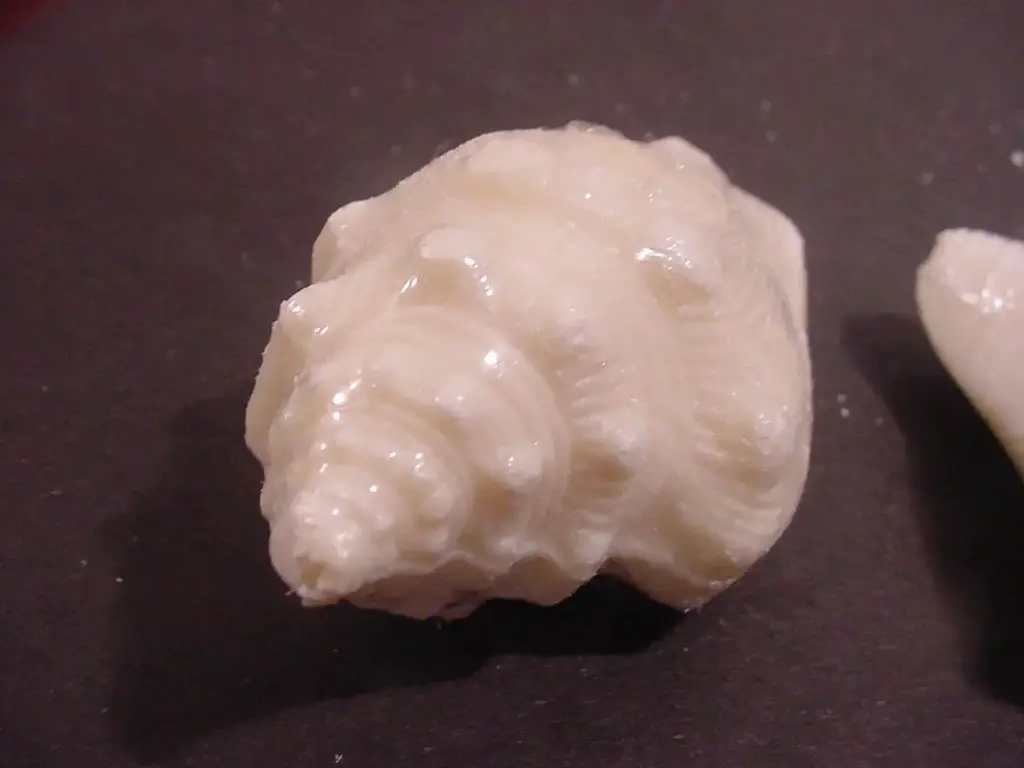

Unique Shapes and Textures

One of the biggest benefits of mold soaps is the ability to create unique shapes and textures. While a basic slab mold will produce a smooth rectangular bar, creative molds allow you to make soaps shaped like shells, roses, geometric shapes, animals, and more. The mold determines the final form of the soap, so the possibilities are endless when using shaped molds. You can also create novel textures like honeycomb, waves, or swirls.

According to a thread on the Soapmaking Forum, shaped molds like shells or honeycombs allow you to achieve textures that would be difficult to accomplish otherwise (Source).

Customizability

Mold soaps provide more customization options compared to basic slab soaps. You can choose molds that align with a theme, holiday, season, or specific branding. For example, you could make heart-shaped soaps for Valentine’s Day, shell-shaped soaps for beach trips, or branded soaps promoted by your business. The shape and design possibilities are endless.

As one Reddit user commented, silicone molds are great for custom soaps like milk soaps where you want a specific shape (Source).

Creativity and Artistry

Using creative soaping molds allows you to express your creativity and artistry. You can explore new designs and find novel ways to decorate your soaps. From sculpting delicate flowers to swirling dye techniques, mold soaps provide a canvas for innovation.

The unique shapes and textures achieved with mold soaps also allow you to create true soap art. You can design intricate soaps that look like works of art. The creative possibilities stretch far beyond basic slab bars.

Common Mold Soap Shapes

Mold soaps come in a variety of fun and creative shapes. Some of the most popular mold soap shapes include:

Flowers, fruits, animals

Flower shapes like roses, daisies, and orchids are very common for mold soaps. Fruits like strawberries, oranges, and lemons are also popular. Animal shapes like bears, frogs, ducks, and turtles allow for cute soaps kids love.

Hearts, stars, moons

Hearts are a classic romantic shape for soaps, great for gifts. Stars and moons appeal to night sky and celestial lovers. These shapes also work well for baby shower soaps.

Logos, numbers, letters

Custom soaps can be made using letter molds for monograms. Number soaps appeal to the birthday crowd. Logos allow companies to create branded soaps for promotions or gifts.

Using Mold Soaps

Mold soaps are designed to be lathered and spread into molds as a release agent. It’s important to build up a nice thick lather before application. According to experts at Ceramic Arts Daily, “make sure your model is 100% dry before pouring plaster” when using a soap mixed with water (https://community.ceramicartsdaily.org/topic/20025-plaster-mold-making-problems/). This helps the soap adhere and build an effective release barrier.

When lathering mold soap, be generous in the amount used and fully coat all surfaces of the mold. Pay close attention to crevices and intricate areas. Let the lather sit for a minute or two before pouring your casting material. Always do a test pour first with a new mold soap to ensure proper release.

Proper storage helps prolong the life of mold soaps. Keep unused soap bars in an airtight container to prevent drying out. For liquid soaps, replace the lid securely after each use. Store away from direct sunlight and extreme temperatures. With proper care, mold soap can be reused many times before needing replacement.

Troubleshooting

Making mold soaps can sometimes run into issues like cracking, sticking to molds, or other imperfections. Here are some tips for troubleshooting common mold soap problems:

To prevent cracks, avoid overheating or cooling your soap too quickly. Slowly bring your soap to thick trace before pouring into molds. Insulate your molds well and allow to saponify for 24-48 hours before unmolding (Source).

If cracks do form, you can fill them in by rubbing a small amount of melted soap base into the crack after unmolding. Sanding or planing your bars can also help smooth over imperfections (Source).

To unmold cleanly, line your molds with freezer paper or silicone liners if possible. Allow soap to fully setup for at least 24 hours before attempting to unmold. If using silicone molds without liners, avoid recipes with high amounts of soft oils. Unmold within 12-24 hours and do not allow soap to set up fully in the mold (Source).

Creative Mold Soap Projects

Mold soaps open up a world of creativity when it comes to designing fun and artistic soaps. Here are some ideas for creative mold soap projects:

Layering colors and scents – One of the easiest ways to get creative is to layer different colored batters and complementary scents. For example, you can pour a base layer of blue soap scented with lavender, then add a layer of yellow soap scented with lemongrass. The layers will create a striped effect when cut.

Incorporating herbs or exfoliants – Dried herbs like lavender buds, oats, or coffee grounds can be gently pressed into the surface of mold soaps to provide visual interest and skin-softening exfoliation. Just make sure to account for the extra ingredients when calculating your lye solution.

Embedding objects – Small toys, beads, seeds, or dried flowers can be artistically arranged and embedded into the soap batter before it sets. Popular embed options include plastic animals for kids’ soaps or dried flower petals for a natural, spa-like aesthetic.

The possibilities are endless when it comes to decorating and designing mold soaps. Be creative with colors, layers, scents, textures, and objects embedded in your soap molds. Part of the fun is experimenting to create your own custom soap art!

Conclusion

In summary, mold soaps are a fun and creative way to make customized soaps at home. Mold soaps start with a soap base that is melted and poured into molds to set up. Silicone molds are a popular option because they are flexible, durable, and easy to unmold. The soap formulation and ingredients like oils, colors, and scents can create a wide variety of artistic soaps. Mold soaps allow hobbyists and small businesses to make personalized soaps for gifts or sale. The creative possibilities are endless when making mold soaps.

The appeal of mold soaps is the ability to customize and create artistic soaps without needing advanced soapmaking skills. Mold soaps are often easier and faster than handmade soaps from scratch. Hobbyists enjoy experimenting with mold shapes, colors, and scents to design fun soaps. The molded shapes like animals, flowers, and more add whimsy and personality. Mold soaps can reflect seasonal themes, special occasions, or recipients’ hobbies and interests. Ultimately, mold soaps enable creativity and self-expression through soapmaking.