What Is Shilpkar Clay?

What is Shilpkar Clay?

Shilpkar clay is a unique type of natural clay found primarily in central India. The name “Shilpkar” comes from the Hindi word meaning “craftsman”, referring to the clay’s extensive use in pottery and sculpture. Shilpkar clay has a high iron content which gives it a rich reddish-brown color when fired or oxidized. It has excellent plasticity and workability which enables artisans to hand-build intricate objects. When fired at high temperatures between 2100°F – 2300°F (1150°C – 1250°C), Shilpkar clay achieves low porosity, high strength, and becomes vitrified into a non-absorbent ceramic material. These properties make it suitable for functional ware as well as decorative sculpture. Shilpkar’s high iron content also allows the development of metallic copper, blue, and green colors through controlled firing conditions. The clay can be polished to a smooth, glassy finish. When examined under magnification, Shilpkar clay’s particles have an angular structure that interlock well for good dry strength. Overall, Shilpkar clay is known for its versatile working properties, rich color, and ability to be fired at high temperatures for functional ceramic use.

Origins and History

Shilpkar clay originates from the Thar Desert region of Rajasthan in northwestern India. This natural clay has a long history of use in the region dating back over 400 years. The indigenous tribes of Rajasthan, including the roaming bands of Kalbeliyas and Saperas, discovered deposits of this fine clay in the arid desert landscape centuries ago. They recognized the clay’s versatile properties and pioneered its use for traditional pottery and crafts.

The term “Shilpkar” means “artist” or “sculptor” in Hindi, reflecting the artisanal origins of working with this clay. Skilled potters and craftsmen passed down their techniques for processing and working with Shilpkar clay over generations. Even today in rural Rajasthan, many artisans continue to use time-honored, traditional methods for extracting Shilpkar clay from the desert and turning it into beautiful, handmade ceramics.

Geographic Distribution

Shilpkar clay is native to the Thar Desert region of Rajasthan in northwestern India. This arid area experiences extreme temperatures, with summer highs reaching 120°F (49°C) and winter lows around 30°F (-1°C). The challenging climate has helped produce Shilpkar’s unique properties over centuries of geological changes.

India remains the primary source of Shilpkar clay in the world today. Rajasthan accounts for over 80% of the global production, with the major deposits concentrated around the districts of Jaisalmer, Barmer, Jodhpur, and Bikaner. Smaller reserves can be found in the Indian states of Gujarat, Punjab, and Haryana.

Outside of India, minor deposits of clays similar to Shilpkar have been found in Pakistan, Bangladesh, Myanmar, and Nepal. However, these clays tend to differ somewhat in color, plasticity, firing range, and other properties compared to the original clay from Rajasthan.

Attempts have been made to source or produce comparable clay for artisanal and industrial uses in other parts of the world like Africa, the Middle East, Europe, and North America. But so far, no equivalent substitute has matched the unique qualities of the original Shilpkar clay from India.

Unique Properties

Shilpkar clay has several unique properties that distinguish it from other clays. Its most notable characteristic is its incredibly smooth, fine texture. When wet, Shilpkar clay has an almost silky feel and can be shaped and molded with ease. It has high plasticity meaning it can be stretched and manipulated into thin sheets without cracking or breaking apart. The clay fires to a light cream color with very little impurities or discoloration. It has high green strength in its unfired state, allowing artisans to construct larger works that won’t collapse or slump before firing. Shilpkar clay fires to an extremely durable bisque with very low porosity. This makes it perfect for functional wares that need to hold liquid without leaking. It also has excellent dry mechanical strength, giving it durability in finished pottery pieces. Unlike some clays, Shilpkar has low shrinkage during drying and firing. This dimensional stability allows for precision and consistency in the clay sculpting and firing process.

Overall, Shilpkar clay’s smooth texture, high plasticity, light color, low porosity, mechanical strength, and dimensional stability give it unique properties that make it one of the finest and most versatile pottery clays in the world.

Manufacturing Process

Shilpkar clay is extracted through an intensive process that aims to retain its unique properties and purity. The clay is sourced from deep deposits found in select regions, often requiring specialized mining techniques. Once extracted, the clay goes through a complex sequence of steps:

– Crushing – The clay is crushed into smaller pieces to make processing easier.

– Grinding – The crushed clay is ground into a fine powder using heavy machinery.

– Hydrating – The powdered clay is mixed with water to create a hydrated clay slurry.

– Sieving – The slurry is sieved to remove impurities and objects.

– Settling – The sieved slurry sits in settling tanks, allowing different densities of clay to separate.

– Spray Drying – The refined slurry is sprayed into a drying chamber to remove moisture.

– Milling – The dried clay is milled into a smooth, uniform powder optimized for downstream uses.

– Packaging – The final milled powder is packaged while minimizing contamination.

This intensive process preserves the purity and properties of the Shilpkar clay, removing impurities and creating an optimized base material. The complexity reflects the value placed on maintaining the clay’s natural qualities.

Uses and Applications

Shilpkar clay is valued for its versatility and has been used for a wide range of purposes throughout history. Here are some of the most common uses and applications of this unique clay:

Pottery

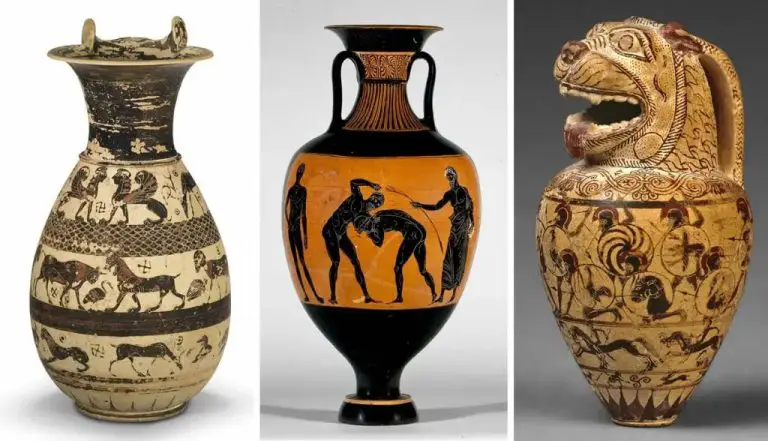

One of the oldest and most widespread uses of Shilpkar clay is for making pottery. The plasticity, strength, and heat resistance make it an ideal clay body for throwing on the potter’s wheel or handbuilding techniques. Shilpkar clay can be used to create anything from basic earthenware pots and bowls to elaborate artistic pieces.

Sculpture

In addition to pottery, Shilpkar clay is also popular for sculpting figurines, idols, busts, and other artistic works. The smooth texture allows for intricate detailing and makes it easy to carve and mold the clay. Many traditional sculptures and terracotta idols in the region are made from Shilpkar clay.

Tiles and Brick

The high heat resistance and strength of fired Shilpkar clay makes it suitable for creating floor and wall tiles as well as bricks for construction. Tiles and bricks made from Shilpkar clay are durable and weather-resistant.

Cookware

Shilpkar clay is sometimes used to produce utilitarian cookware items like tandoor ovens, cooking pots, and tagines. The natural properties allow it to withstand high cooking temperatures without cracking.

Artisanal Crafts

Shilpkar clay has a long history of being used in traditional arts and crafts across the region where it originates. The unique properties of this clay make it well-suited for handcrafting delicate and detailed objects. Skilled artisans work with Shilpkar clay to produce a range of artifacts and functional wares.

One of the most popular artisanal uses of Shilpkar clay is for making clay idols and figurines. The clay can be molded into intricate shapes and designs to create religious idols and statues for temples and shrines. When fired, the idols retain fine details and take on a beautiful, smooth finish. Deities, animals, musicians and other symbolic figures are commonly crafted from this clay.

Shilpkar clay is also used for making decorative objects like vases, jars, pots and lamps. The clay’s earthy red tone and ability to be shaped into thin walls makes it ideal for pottery. Skilled potters throw and hand-build detailed vessels with markings or painted designs. The fired pottery often has a lustrous look, smooth feel and long-lasting durability.

In addition to sculpture and pottery, Shilpkar clay is crafted into jewelry and ornamental pieces. The clay can be rolled out thin, cut into shapes and fired to make durable beads, pendants, earrings and bangles. Jewelry makers imprint or engrave designs into the clay before firing for a shiny, polished finished product. Tiny clay tiles are also cut to make ornate mosaic patterns.

Overall, the unique plasticity, strength and luster of fired Shilpkar clay has made it a favored material for artisanal works and cultural artifacts for centuries. The clay’s durability allows craftspeople’s creative works to be appreciated and passed down through generations.

Modern Applications

Shilpkar clay is finding innovative modern uses thanks to its unique properties. Architects and engineers are incorporating Shilpkar clay into building materials like bricks, tiles, and wall finishes. This provides natural insulation, moisture regulation, and aesthetic appeal. Shilpkar clay is also being used in advanced filtration systems to purify water in an eco-friendly manner.

Additionally, Shilpkar clay is gaining popularity in modern art and design. Sculptors and ceramicists create beautiful works by blending Shilpkar clay with other natural materials like wood, fibers or metals. Product designers are also utilizing Shilpkar clay for making organic, nature-inspired home decor, tableware and jewelry. Its rich textures and earthy colors provide a warm, natural feel.

As an abundant and sustainable local material, Shilpkar clay allows for innovative modern applications while preserving tradition and cultural roots. The unique versatility and aesthetic of Shilpkar clay ensures its continued relevance for the future.

Environmental Impact

The production of Shilpkar clay can have both positive and negative impacts on the environment. On the positive side, Shilpkar clay is a natural and sustainable material. The clay deposits are abundant and renewable, and have been mined for centuries with no signs of depletion. The production process is relatively low-impact, requiring only basic tools and manual labor.

However, there are some concerns around the environmental effects of mining Shilpkar clay. Digging clay from open pit mines can lead to deforestation and loss of topsoil in mining areas. The mines may also disrupt local wildlife habitats and vegetation. There is also a risk of soil erosion if mines are not properly managed and rehabilitated after use.

Furthermore, the wood-fired kilns traditionally used to fire Shilpkar pottery can generate large amounts of smoke and carbon emissions. Modern gas or electric kilns have helped reduce emissions from firing. But wood kilns are still widely used, contributing to local air pollution.

On balance, Shilpkar clay remains one of the more eco-friendly and sustainable ceramics materials. But there is room for improvement in mining and production practices to further reduce its environmental footprint.

Future Outlook

The future looks bright for Shilpkar clay production and use. As an artisanal and eco-friendly material, Shilpkar clay aligns well with rising consumer demand for sustainable products. The clay’s versatility also positions it well to be utilized in innovative new applications as technology advances. Here are some key trends that will shape the future of Shilpkar clay:

Increasing awareness and demand: As knowledge spreads about Shilpkar clay’s unique properties and sustainability benefits, demand is projected to increase globally. Brands are beginning to highlight the clay in marketing as consumers show interest in natural, handmade products.

New production methods: To meet demand, production may shift from small village operations to larger-scale facilities while maintaining the clay’s handcrafted essence. However, care must be taken to avoid over-mining the clay’s limited natural reserves.

Advanced applications: From bio-based composites to high-performance ceramics, researchers are discovering new ways to use Shilpkar clay in cutting-edge applications. Its high plasticity allows extensive shaping and molding capabilities.

Supporting local artisans: Organizations and ethical brands are working to preserve the cultural heritage around Shilpkar by generating livelihoods for local artisans skilled in clay crafts.

Overall, Shilpkar clay is poised for a bright future thanks to its renewable properties and immense versatility. Sustainable production and fair trade will be key to protecting the communities and natural ecosystems that have relied on this remarkable clay for centuries.