What Is Terra Cotta In Clay?

Terra cotta, which literally means “baked earth” in Italian, is a type of hard, fired clay used for pottery and building materials. It has a long history dating back thousands of years to ancient Mesopotamia, Egypt, Greece, and Rome where it was used to create pottery, roof tiles, and decorative architectural elements.

Over time, terra cotta developed as an important building material prized for its durability, weather resistance, and fire proof properties. Around 1850, terra cotta production began on a larger scale in the United States to create fireproofing units and decorative facade elements. Architectural styles like Beaux-Arts and Art Deco utilized glazed terra cotta exteriors that added vibrant color to buildings. Terra cotta remains an attractive and resilient material today used for both historical restoration projects and modern construction.

What is Terra Cotta Made Of?

Terra cotta is a type of earthenware pottery made from clay. The clay composition and manufacturing process give terra cotta some unique properties.

Terra cotta is made from natural clay, which contains minerals like iron oxide and magnesium. This clay mixture is shaped and then fired at high temperatures between 1800°F – 2100°F. The firing process hardens the clay and sets the color. Natural clay tends to produce terra cotta pottery in earthy red, brown, orange, yellow, and ochre shades.

Terra cotta clays contain iron oxide and other minerals that cause the clay to turn red when fired. The higher the iron content, the redder the terra cotta color will become when fired. Clays with less iron oxide will produce more muted oranges, browns, and yellows. By controlling the clay composition and firing temperature, terra cotta can be produced in a wide range of natural earthen colors and textures.

Types of Terra Cotta

There are several main types of terra cotta used for different purposes:1

Architectural Terra Cotta

Architectural terra cotta refers to terra cotta used for building exteriors and facades. It may be glazed or unglazed. Glazed architectural terra cotta has a ceramic glaze finish and is used for decorative embellishments on buildings. Unglazed architectural terra cotta provides a durable, weather-resistant exterior building material.

Garden Terra Cotta

Garden terra cotta includes pots, planters, urns, fountains and other decorative items used for gardens and landscaping. Garden terra cotta may have a glazed or unglazed surface finish. It is designed to withstand outdoor weather conditions.

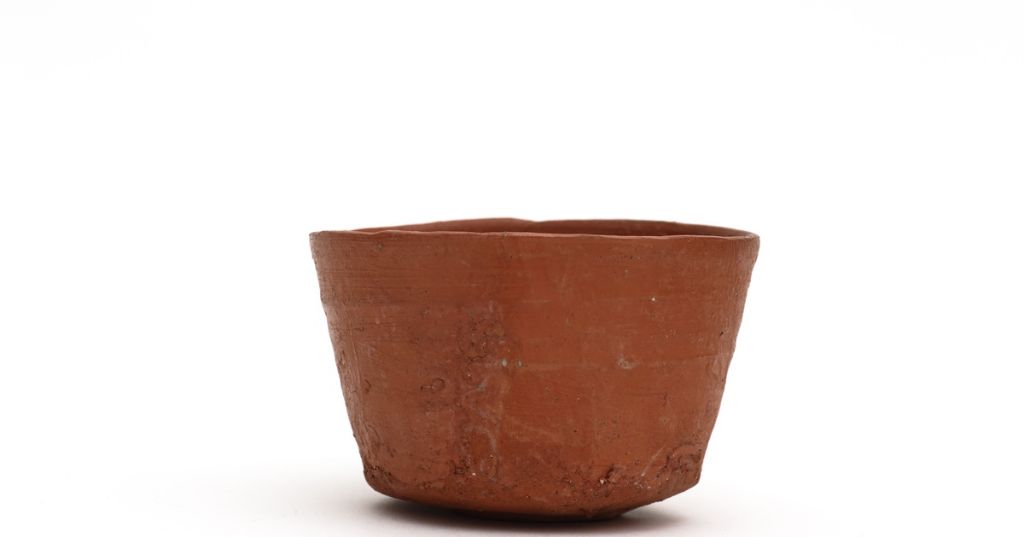

Terra Cotta Pottery

Terra cotta pottery encompasses a wide range of ceramic vessels and objects like vases, bowls, lamps, and sculpture. Terra cotta pottery can be glazed or left with the natural clay surface. It is generally hand-formed and fired to make decorative, functional, or artistic terra cotta ware.

Terra Cotta Production Process

The production process for terra cotta involves several key steps:

First, the clay must be mined from deposits underground. Clay deposits are found in many locations worldwide and vary in color and composition based on the minerals present.

Once mined, the clay goes through a purification process to remove any rocks, organic material or other impurities. This produces a smooth and consistent clay body for shaping.

The purified clay is then molded or shaped into the desired terra cotta forms. This is done using molds and techniques like ram pressing, extrusion or throwing on a pottery wheel. Complex shapes may require detailed and specialized molds. According to Geer, terra cotta makers employ a variety of molding methods to achieve intricate architectural details.

After shaping, the terra cotta pieces undergo controlled drying to remove moisture from the clay slowly and prevent cracking. Once dry, the terra cotta is fired in a kiln at high temperatures ranging from 900-1200°C to permanently harden the clay through sintering.

Finally, a glaze may be applied to the fired terra cotta to create a glassy coating and decorative effects. The glazed pieces are fired again to fuse the glaze to the terra cotta.

Terra Cotta Properties

Terra cotta has some unique properties that make it well-suited for certain applications:

Porosity

Terra cotta clay has a porous structure that allows moisture to evaporate through the material. This makes it resistant to damage from freezing and thawing cycles. The porosity also provides insulation, trapping air within the clay body.1

Strength

When fired, terra cotta develops high compressive strength while still being relatively lightweight. This structural strength allows terra cotta to be used for load-bearing construction elements like bricks or architectural decoration.1

Weather Resistance

Properly glazed terra cotta has excellent resistance to wind, rain, snow and freezing temperatures. The glaze provides a water barrier while allowing moisture to escape through the clay body. This weather resistance made terra cotta a popular exterior building material.

Thermal Properties

As an insulating ceramic material, terra cotta helps regulate interior temperatures. The porous clay traps air pockets that provide thermal mass to reduce heat transfer. This made terra cotta useful for both heating stoves and building cladding.

Notable Uses of Terra Cotta

Terra cotta has been used throughout history for both architectural and decorative purposes. Some of its most notable uses include:

Architectural Facades – Glazed architectural terra cotta became very popular in the late 19th and early 20th centuries as a cladding material for building facades. The clay’s durability, fire resistance, and ability to be molded into ornate decorative elements made it ideal for the exteriors of commercial, institutional and residential structures. Terra cotta facades can be seen on many historic buildings across the United States, including New York’s Woolworth Building, Louis Sullivan’s designs, and Chicago’s Wrigley Building.

Sculpture – Terra cotta’s durability and ability to hold fine detail make it a common medium in sculpture. It has been used for sculpture and statuary since antiquity. Large-scale architectural terra cotta sculpture gained popularity in the late 19th century and includes works like the Washington Square Arch, the Queensboro Bridge sculptures, and the Atlas statue at Rockefeller Center in New York.

Pottery – Terra cotta has an extremely long history of being used to create pottery and ceramics. From ancient Greek vessels to the terra cotta warriors of Xian, firing clay has long allowed artisans to create durable and decorative objects. Terra cotta continues to be a popular clay for studio potters and ceramicists.

Tiles – The durability and ornamental potential of terra cotta has made it ideal for floor and wall tiles since ancient times. Glazed architectural terra cotta tiles were popular in the late 19th and early 20th centuries in America to decorate building interiors. Terra cotta remains a key material for decorative tilework today.

Sources:

https://studiopotter.org/architectural-terra-cotta-1900-1990

https://en.wikipedia.org/wiki/Architectural_terracotta

Advantages of Terra Cotta

Terra cotta has several notable advantages that have made it a popular material for thousands of years. Some of the main benefits of terra cotta include:

Durability

Terra cotta is known for its durability and weather resistance. It can last for decades or even centuries when properly cared for. The natural clay material stands up well to sun, rain, and changing temperatures. Terra cotta’s longevity makes it a wise investment.

Aesthetics

Many find the look and feel of terra cotta to be highly appealing. Its earthy red-orange color and slightly irregular surfaces have an organic, handmade quality. Terra cotta pots and roof tiles lend visual warmth and rustic charm to indoor and outdoor spaces.

Availability of Clay

Clay suitable for making terra cotta can be easily obtained worldwide, making production relatively affordable and accessible. Quality terra cotta items can be created almost anywhere using locally sourced clays (“Amazing Benefits of Terra Cotta Pots”).

Sustainability

Since terra cotta comes from natural clay and can be reused or recycled, it is considered a sustainable, eco-friendly material. Terra cotta production has a low carbon footprint compared to materials like concrete or plastics.

Disadvantages of Terra Cotta

While terra cotta has many benefits, it also has some drawbacks to consider:

Terra cotta is heavy and brittle when made too thin. The clay material is dense and heavy, which makes larger terra cotta items difficult to move or transport. If terra cotta pieces are not thick enough, they can become brittle and prone to cracking or breaking.

Terra cotta is also porous and requires sealing. The natural clay is permeable, meaning it can absorb liquids. This allows moisture to evaporate through terra cotta pots, but it also means the material must be glazed or sealed to prevent damage from water absorption over time. Unglazed terra cotta will soak up water, which can lead to leaks, drips, staining, and deterioration if a sealer is not applied.

Proper sealing is required for outdoor terra cotta use, as noted by https://www.ohiotropics.com/2019/02/24/terra-cotta-pots-for-houseplants/. Sealing the exterior will help protect it from damage due to water and weathering. Sealing the interior helps prevent moisture buildup that could harm plants. Terra cotta must be resealed periodically to maintain its integrity.

Modern Terra Cotta Production

Terra cotta production today is highly automated and efficient compared to historic methods. Modern terra cotta is produced in a factory setting using specialized equipment and streamlined processes to maximize output.

Key steps in the modern production process include clay preparation, molding/pressing, drying, glazing, and firing. Clays are carefully mixed and refined to achieve the desired properties. Molds and mechanical presses shape the terra cotta into forms. Controlled drying rooms and kilns allow for precise control over moisture content and firing.

Glazes and colors are applied through spray systems for consistency. Kilns utilize gas or electric heating to fire products at over 2,000°F. Conveyor systems move terra cotta efficiently through production stages.

Automation allows modern terra cotta factories to produce a wide range of standard and custom products with precision and efficiency. The scale of production is far beyond what could be achieved with manual processes. Quality control testing ensures products meet technical specifications.

While production methods have modernized, the fundamentals of working with natural clays and high-firing remain unchanged. The terra cotta produced today maintains the durable, aesthetic properties that have made it valued for centuries. Modern manufacturing advancements simply allow more streamlined and large-scale production.

[https://fitchfoundation.org/project/2008-american-architect-engineers-in-the-19th-century/]

Future of Terra Cotta

Despite being an ancient material, terra cotta is experiencing a resurgence in popularity for both restoration projects and new construction. With its durability, natural aesthetic, and energy efficiency, terra cotta is well-suited for the sustainability goals of modern architecture. Terra cotta provides an attractive and long-lasting cladding that can last over 100 years with proper maintenance.

Some innovative new uses for terra cotta include ventilated façade systems, structural clay tile for floors and walls, and glazed terra cotta with vibrant colors and patterns. The natural properties of terra cotta also make it ideal for green building projects focused on energy conservation. For example, the mass of terra cotta provides thermal storage capabilities to help regulate interior temperatures.

The future of terra cotta looks bright as architects and designers rediscover its beauty and versatility. Terra cotta production is also becoming more automated, which improves consistency and can lower costs. With continued technological advancement and creative applications, terra cotta will likely remain an important building material for centuries to come.