What Is The Best Clay For Food Safe Dishes?

Clay has been used for making dishes and pottery for thousands of years across many cultures. The unique properties that make clay moldable when wet but hard and durable when fired, allow it to be shaped into bowls, plates, cups, and other vessels. Homemade clay dishes have seen a revival in recent years as more people discover the joys of creating their own functional pottery.

However, not all clay is well-suited for items that will come in contact with food and beverages. Using the wrong type of clay can pose health risks. It’s important to understand the properties of clay that make it safe for dishes. Key factors are composition, firing method, and glazes. With the right clay and firing process, homemade dishes can be food-safe, durable, and beautiful.

This provides an overview of the history and popularity of clay dishes, emphasizes the need for food-safe materials, and sets the stage for the article to delve into specifics on clay types and proper manufacturing methods.

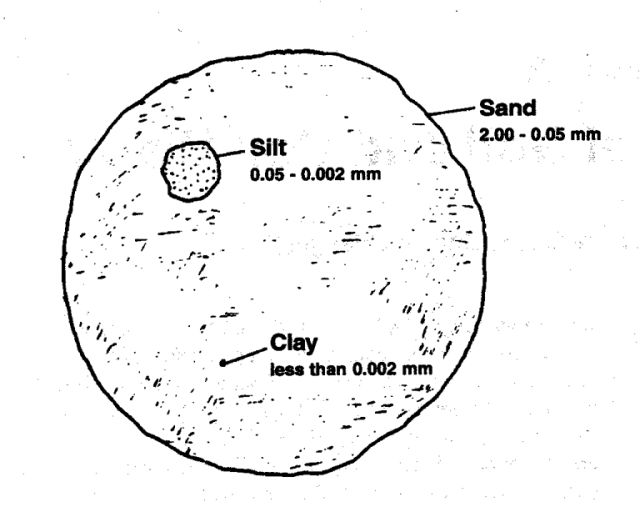

Common Clay Types

There are four main types of clay that are commonly used for making dishes and other functional pottery:

Earthenware

Earthenware is a porous clay that is fired at lower temperatures, usually between 1000°F – 1200°F. It has a coarse texture and absorbs water easily. Earthenware clays are some of the most accessible and versatile for working with.

Stoneware

Stoneware clays are denser and less porous than earthenware. They are fired between 2200°F – 2400°F. The higher firing temperature makes stoneware more durable and water-resistant. Stoneware has a finer texture and commonly has a gray or brown color.

Porcelain

Porcelain clays are very dense and non-porous, fired between 2200°F – 2400°F. Porcelain has a bright white color and smooth, glass-like texture when glazed. It is commonly used for tableware and art pottery. Porcelain is more difficult to work with than other clays.

Terracotta

Terracotta is an unglazed, low-fired earthenware clay with a distinct orange/red color. It is porous and not waterproof, making it unsuitable for dishes. Terracotta is mainly used for flower pots, sculpture, and architectural decoration.

Properties of Food Safe Clay

When selecting clay for food safe dishes, it’s important to consider certain properties that make the clay safe for food contact.

The clay body and glaze should be non-porous. Porosity allows bacteria to get trapped in the clay, creating a risk of contamination. Non-porous clay has a smooth, glassy surface that prevents bacterial growth.

The glaze must also be lead-free. Lead can leach from the glaze into food, causing lead poisoning. Food safe glazes use alternatives like zinc, potassium, and magnesium instead of lead.

Clay dishes must withstand heating without cracking. Thermal shock resistance allows clay to go from freezer to oven without breaking. Stoneware, porcelain, and borosilicate glass clays have excellent thermal properties.

Choosing a non-porous, lead-free clay with proper heat resistance results in durable, food safe dishes.

Best Clays for Dishes

When it comes to selecting the ideal clay for food safe dishes, there are a few specific types that stand out as the best options.

Porcelain is widely regarded as the optimal clay body for dishes. It is non-porous, hard, and transparent, which makes it resistant to stains and durable. Porcelain can withstand repeated use and frequent washing without deteriorating. It’s also highly resistant to thermal shock, so it can transition between hot and cold temperatures without cracking or crazing.

Stoneware is another top choice for dishes. While not as durable as porcelain, stoneware is impermeable and can hold up well to daily use. It’s available in natural colors or can be glazed. Quality stoneware dishes are opaque rather than transparent.

Recommended brands for high quality porcelain and stoneware clays suitable for dishes include MudWorks, Highwater Clays, Clay Planet, Axner, Laguna Clay, and Continental Clay. These companies offer clay bodies that meet FDA standards for lead-free glazes and food safety.

When selecting a clay body, it’s also important to consider the appropriate firing temperature. Porcelain and stoneware clays require high fire temperatures above 2200°F. Specialized glazes are also formulated for high fire applications. Following manufacturer guidelines ensures proper vitrification for optimal durability and dishware safety.

Using Earthenware

Earthenware is a commonly used clay for making dishes and cookware. It has some advantages but also important limitations to consider.

Earthenware is fired at lower temperatures compared to stoneware or porcelain. This means it is more porous and prone to absorbing liquids. For food safety, earthenware requires lead-free glazes. Unglazed earthenware can release lead and other toxins when interacting with acidic foods.

Due to its porous nature, earthenware tends to be less durable than stoneware or porcelain. It can more easily crack or chip. Earthenware dishes need to be handled with greater care.

Earthenware has some use limitations. It is not recommended for oven or stovetop use since it cannot withstand very high temperatures. Long simmering or cooking acidic foods like tomatoes can slowly damage the glaze over time. Earthenware is best used for short-term food storage, or serving cold or room temperature foods.

With proper lead-free glazing and care in handling, earthenware can be a good option for making dishes. But its porosity and lower durability limit its uses compared to other clays.

Clay Safety Standards

When choosing a clay for food safe dishes, it’s important to select one that meets safety standards established by government agencies. Two key standards are from the U.S. Food and Drug Administration (FDA) and California’s Proposition 65.

FDA Standards

The FDA has established limits on the amounts of lead and cadmium that are permissible in ceramic articles intended for food contact. Lead is restricted to not more than 3.0 μg/ml, while cadmium is limited to not more than 0.25 μg/ml.

Reputable clay suppliers will have lab test results showing their products comply with these FDA standards. This provides assurance the clay is safe for baking, serving, and storing food and drink.

California Prop 65

California’s Proposition 65 requires warning labels on products containing chemicals known to cause cancer, birth defects, or reproductive harm. Clays sold in California that contain lead or cadmium exceeding Proposition 65 limits must be labeled.

To avoid Prop 65 labeling requirements, clay products should be tested to verify they don’t exceed allowable limits for these heavy metals. Meeting FDA guidelines typically ensures compliance with Prop 65 as well.

Choosing a lead-free clay made in the USA or EU is the safest bet for food safe ceramic ware. Always check for certification from the manufacturer that their clay is lead-free and safe for food use.

Firing and Glazing

When making dishes from clay, proper firing and glazing is crucial for safety and durability. Firing refers to heating the clay at high temperatures which causes the clay particles to fuse together in the kiln. Glazing provides a glassy coating that makes the clay non-porous and suitable for food use.

For stoneware clays, aim for a firing temperature between 2200-2400°F. Stoneware becomes vitrified and water-tight at these high temperatures. Porcelain clays require an even higher firing temp of around 2350-2450°F to fully vitrify.

Choose lead-free glazes specifically formulated for high-temperature stoneware/porcelain firing. Lead glazes can leach lead into food and should always be avoided for dishes. Look for glazes made from safe materials like feldspar, silica, kaolin, and food-grade colorants.

Applying the right glaze thickness (around 1/16″) will prevent leaching and chipping. Firing the glazes according to the manufacturer’s specifications will help the glaze melt smoothly onto the clay surface.

Testing your finished pieces with an at-home lead test kit provides peace of mind and ensures your handmade clay dishes are safe for food use.

Making Clay Dishes

Once you have selected the appropriate clay and prepared it for use, it’s time to start shaping it into dishes. There are several techniques you can use:

Handbuilding: This involves molding the clay entirely by hand into the desired shape. Pinch pots, coils, and slabs are common handbuilding methods. This allows you to create unique, organic shapes.

Wheel Throwing: Using a pottery wheel, you can throw clay into symmetrical rounded shapes like bowls, cups, and plates. This takes practice to master the spinning technique.

Molds: Pressing clay into pre-made molds is another option for achieving consistent shapes and designs.

After shaping, allow your unfired clay creations to dry slowly over several days. Then comes the bisque firing, which converts the clay into a permanent ceramic material. Firing typically happens between 1800-2200°F in a kiln. Bisque firing prepares the clay to receive glazes.

Next, apply glazes to your bisque ware pieces using brushes, sponges, or spraying. Glazes come in various colors and textures to give your finished clayware a beautiful surface. They melt and fuse to the clay during the final firing. Use lead-free glazes for functional dishes intended for food use.

After glazing, the clay dish is ready for a final firing to permanently set the glaze. Typical glaze firing ranges from 2200-2400°F. Always follow the glaze manufacturer’s specific firing instructions. And be sure to allow proper cooling of the kiln and clay pieces when firing is complete before handling.

Storing and Caring

Proper storage and care is important for maximizing the lifespan of your clay dishes. Here are some tips:

Avoid Cracks

Clay is prone to cracking if not handled properly. Avoid extreme temperature changes which can cause the clay to expand or contract too quickly. For example, do not put a hot dish straight from the oven into the fridge. Allow it to cool gradually. Also, avoid dropping or knocking the dish as this can cause hairline cracks over time.

Microwave/Dishwasher Safety

Unless specifically labeled as microwave and dishwasher safe, it’s best to avoid putting clay dishes in either appliance. The extreme heat and moisture can damage and crack the clay. Handwashing with mild detergent and a soft sponge is recommended. Avoid abrasive scouring pads.

With proper care, high quality clay dishes can last for many years and remain beautiful functional works of art for your kitchen.

Conclusion

When choosing the best clay for food safe dishes, there are a few key types that stand out. Natural earthenware clays like terracotta and red clay tend to be good options, as they are less porous after firing. Stoneware clays have excellent durability and provide a non-porous finished product that resists staining. Porcelain also makes an ideal clay body for dishes and cooking pots, as it can withstand very high temperatures and creates a smooth, glass-like surface.

To use homemade clay dishes safely, be sure to fire them to the proper temperature and apply a food-safe glaze. Allow dishes to fully dry after washing to prevent bacterial growth. Don’t expose clay cookware to extreme temperature changes, which can cause cracking. With proper care and firing, homemade clay dishes can be just as functional and safe as commercial options.

Crafting your own clay dishes offers many benefits compared to purchasing factory-made ones. You can create pieces in your own custom shapes, colors, and sizes. The process allows for artistic experimentation and satisfaction in making useful, handmade items. Homemade clay dishes often feel warmer and more organic than mass-produced versions. And crafting your own dishes from natural clay allows you to control what materials you’re using and avoid potential chemicals found in commercial glazes.