What Is The Best Knife Steel Called?

Knife steels are an important material consideration when choosing a knife, as the steel greatly impacts performance characteristics such as edge retention, corrosion resistance, and toughness. With so many steel types available, determining the “best” knife steel involves evaluating the key factors and how they align with the intended use of the knife. This article provides an overview of the most important criteria in knife steel selection, profiles popular steel types, and makes a recommendation for the best all-around knife steel based on a balance of key performance traits. Understanding knife steel properties helps inform the ideal steel for a given cutting task.

Hardness

Hardness refers to a steel’s ability to resist deforming when force is applied. It is one of the most important properties for knife blades, as it directly impacts edge retention and durability. Hardness is measured using the Rockwell C scale, with a higher number indicating greater hardness.

On the Rockwell C scale, most quality knife steels fall between 56-64 HRC. A hardness of 56-58 HRC provides a good balance of edge retention and ease of sharpening. Steels in the 60-64 HRC range are very hard and can hold an edge for a long time, but are more difficult to sharpen. For most knives, a hardness of 58-62 HRC offers the ideal combination of edge retention, durability, and sharpenability.

In general, harder steels will retain their edge better but may be more brittle. Softer steels are tougher but lose their edge more quickly. The optimal hardness depends on the intended use of the knife. For tasks that require a very acute edge like slicing, harder steels in the 60-64 HRC range excel. For abusive tasks like digging and prying, slightly softer steels around 56-59 HRC are preferable.

Toughness

Toughness refers to a steel’s ability to resist chipping, cracking or breaking when subject to an impact force (6). A knife blade must have a certain degree of toughness to prevent chipping during normal use. However, extremely high toughness is usually not required for most EDC tasks. The most important factor is finding the right balance of hardness and toughness for the intended uses of the blade (2).

For applications like bushcraft where prying is common, higher toughness steels like 3V may be preferred. But for lighter duties like opening boxes, lower toughness steels can perform well if properly sharpened. Ultimately, choosing a steel with the right hardness to toughness ratio depends on the user’s needs.

While toughness is important, it does not need to be maximized at the expense of hardness and edge retention for EDC uses. Finding the sweet spot of balance should be the goal when selecting a steel (1).

Wear Resistance

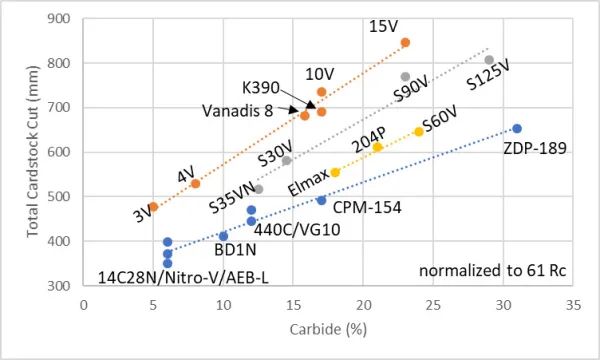

Wear resistance refers to a steel’s ability to resist abrasion and maintain its sharp edge over time and use. This property is critical for edge retention in knives, as a steel that wears quickly will require frequent sharpening and lose its sharpness during use (1).

High wear resistance is desirable for knives that will experience heavy or frequent use. Steels with increased levels of hard carbides, like vanadium carbides, generally demonstrate improved wear resistance. However, wear resistance must be balanced against toughness, as very hard steels can become brittle and prone to chipping (2).

For knives that will undergo rugged use, a moderately wear-resistant steel provides better edge retention than a soft steel while still maintaining enough toughness to withstand impacts. However, for delicate tasks requiring very refined edges, choosing a steel with maximum wear resistance is ideal to minimize the need for frequent sharpening.

Corrosion Resistance

Corrosion resistance refers to a steel’s ability to resist rusting when exposed to moisture. For knife blades, corrosion resistance is an important property to consider as it determines how well the steel will hold up over time with normal use and cleaning. Knives used outdoors or in humid environments will especially benefit from high corrosion resistance.

Rust damage on a knife blade starts out as pitting and discoloration. But over time, it can lead to deterioration that impacts cutting performance. According to testing by Knife Steel Nerds, the most corrosion resistant steels like LC200N and H1 can resist rusting over 10 times longer compared to less resistant steels like 420 and 154CM when exposed to salt spray or high humidity [1]. The high chromium content in these stainless steels forms a protective chromium oxide layer that helps prevent moisture from reaching the steel.

For an ideal all-around knife steel, excellent corrosion resistance should be balanced with hardness, edge retention, and toughness. But for applications where the environment is extra demanding, choosing a steel with maximum corrosion resistance is a priority to maintain long-term durability.

Ease of Sharpening

Sharpenability refers to how easily a steel can be sharpened to a fine edge. Some steels are very easy to sharpen, while others are more difficult and may require more patience. The sharpenability of a steel is strongly influenced by its hardness. In general, the harder the steel, the more difficult it will be to sharpen. However, hardness comes with the benefit of better edge retention.

So there is a tradeoff – harder steels stay sharp longer but are more difficult to sharpen, while softer steels are easier to sharpen but lose their edge faster. For most people, a steel in the middle ground that offers a balance of sharpenability and edge retention is preferable.

The grain structure of the steel also affects sharpenability. Fine grained steels are usually easier to sharpen than coarse grained steels. The precise heat treatment applied to the steel during manufacturing further influences the sharpening characteristics.

For kitchen knives that require frequent sharpening and maintenance, a steel with decent ease of sharpening is important. For fixed blade outdoor knives that won’t see as much sharpening, edge retention could take priority over sharpenability. Understanding the intended use of the knife helps determine the ideal balance between these two factors.

Grain Structure

The grain structure refers to the arrangement and size of the grains in the steel. It has a significant impact on the properties and performance of the steel.

Some common grain structures in knife steels include:

- Fine grained – Smaller and more uniformly sized grains. Provides strength and hardness.

- Coarse grained – Larger grains that are less uniform in size. Tougher but less hard.

- Ultrafine grained – Very small, uniform grains produced by processes like cryogenic treatment. Maximizes hardness and wear resistance.

- Laminated – Alternating layers of hard steel (high carbon) and tough steel (low carbon). Provides a good balance of hardness and toughness.

The optimal grain structure depends on the intended use and desired qualities of the knife. For maximum hardness and edge retention, an ultrafine or fine grain structure is ideal. But this can reduce toughness and make the edge more prone to chipping. A coarse grain offers more resilience but compromises on hardness and wear resistance.

Many high-end knife steels use complex processes to optimize a fine, uniform grain structure that provides an optimal balance of hardness, edge retention and toughness.

Popular Steel Types

Among knife enthusiasts and manufacturers, there are several popular and commonly-used steel types (Guide to the Best Knife Steel). Here are some of the most popular:

154CM – This is a high-carbon stainless steel developed by Crucible Industries. It offers a good balance between hardness, toughness, corrosion resistance and ease of sharpening. 154CM is considered a mid-range steel.

S30V – Developed by Crucible Industries, this steel has high hardness and wear resistance due to increased amounts of vanadium. It maintains razor sharpness well but can be difficult to sharpen. S30V is a premium steel widely used for high-end knives.

S35VN – An improvement over S30V, this steel by Crucible Industries offers better toughness and slightly easier sharpening while maintaining very high edge retention and stain resistance. It is one of the most popular high-end steels.

CPM S110V – With increased amounts of vanadium and chromium, this Crucible steel achieves exceptional hardness, wear resistance and edge retention. However, it can be difficult to sharpen and is brittle. CPM S110V is regarded as a top-tier steel.

These are some of the most well-regarded and popular steels used for knives, though there are many other variations and specialty steels available (Knife Steel Guide). Manufacturers constantly develop new steels aiming for the optimal balance of key properties.

Best All-Around Steel

When it comes to the best all-around steel for knives, most experts recommend CPM S35VN. This steel was developed by Crucible Industries specifically to have an optimal balance between hardness, toughness, and corrosion resistance. S35VN has a carbon content of around 1.4% and includes micro-additions of niobium, vanadium, and nitrogen. This mixture of elements allows S35VN to achieve a hardness in the range of 60-62 HRC, while still maintaining decent toughness and the ability to take a keen edge.

S35VN improves upon earlier steels like 154CM by having more carbon and chromium, which increases hardness and corrosion resistance. The addition of niobium also helps to refine the grain structure. Many users praise S35VN for having excellent edge retention and stability. While not quite as stain and rust resistant as something like H1 steel, it provides ample corrosion resistance for most users. S35VN is easier to sharpen than very hard steels like S90V, yet it still maintains an edge well. The balance of properties and well-rounded performance is why S35VN is considered an excellent all-around steel for most EDC uses.

Conclusion

When choosing the best knife steel, there are several key factors to consider. The ideal steel will balance hardness, toughness, wear resistance, corrosion resistance, and ease of sharpening for the intended use. While there is no universally perfect steel, carbon steels like 1095 and O1 offer a good blend of these properties for most applications. Stainless steels like 154CM, VG-10, and S30V prioritize corrosion resistance but can be more difficult to sharpen. Exotic steels like M390 and ZDP-189 push hardness and edge retention to the extreme but sacrifice toughness and ease of sharpening in the process. When selecting a steel, it’s important to match the characteristics of the steel to the demands of the application. For a general purpose or outdoor knife, balanced steels like CPM-S35VN and 14C28N provide a good mix of all considerations. Consulting manufacturer spec sheets and product reviews can help narrow options to find the optimum steel for any knife’s intended role.