What Is The Best Type Of Spray Booth?

A spray booth is an enclosed structure used to contain overspray and control air flow during the process of applying paints, coatings or other sprayable materials. The purpose of a spray booth is to capture overspray and reduce exposure to hazardous materials while providing a controlled environment for optimal transfer efficiency and finish quality.

The main types of spray booths include:

- Dry filter spray booths

- Water wash spray booths

- Downdraft spray booths

- Semi-downdraft spray booths

- Side draft spray booths

In this article, we will take a deeper look at each of these spray booth types, their unique benefits, recommended uses, and important considerations when selecting the optimal spray booth for your application.

Dry Filter Spray Booths

Dry filter spray booths use a filter made of layered fiberglass or polyester to capture overspray. The filters trap paint particles as contaminated air is pulled through them. This type of booth requires frequent filter changes as the filters become clogged with paint over time.

Pros of dry filter booths:

- Lower operating costs since no water or chemicals are used

- Produce less waste compared to water wash booths

- Require less maintenance than water wash booths

Cons of dry filter booths:

- Struggle with high production volumes as filters clog faster

- Not ideal for some types of spray compounds that require water to capture

- Require more filter changes compared to water wash

Dry filter booths provide a more budget-friendly option for lower production painting operations. They can effectively capture paint overspray as long as the filters are changed regularly. However, frequent filter changes make them less suited for high output painting (source).

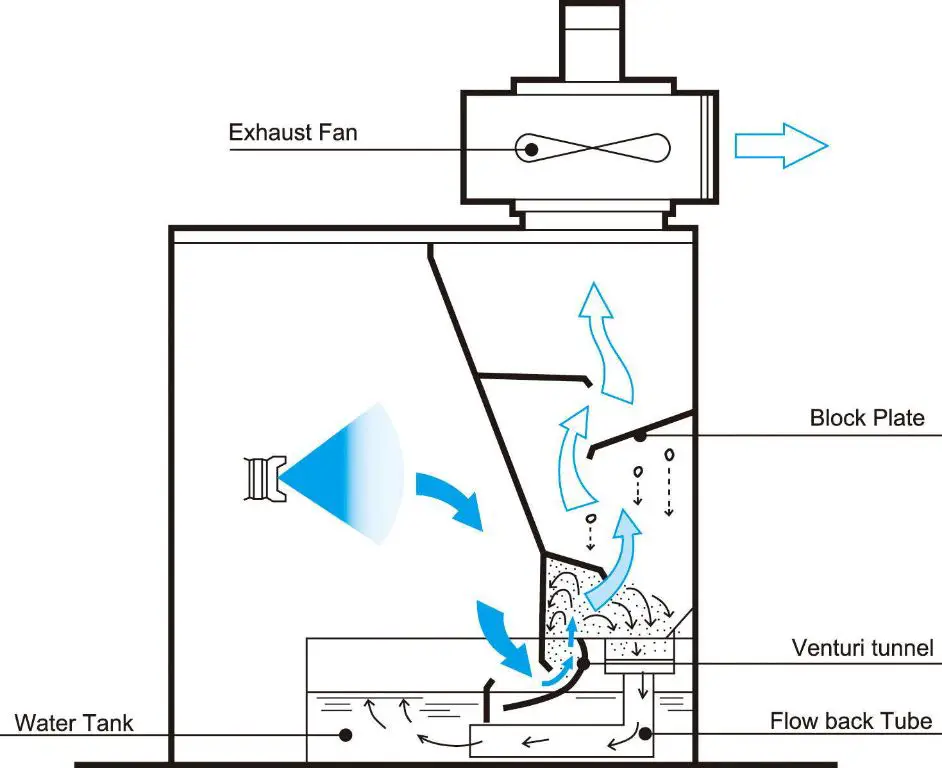

Water Wash Spray Booths

Water wash spray booths use a curtain of water to capture overspray and particles rather than relying solely on filters. The water curtain captures the overspray and particles and sends them down to a collection tank where they can be removed. The water is then recirculated and reused in the system.

According to SprayPaintBooth.com, water wash spray booths offer several advantages compared to dry filter booths:

- They are very efficient at capturing overspray, resulting in less contamination in the air.

- They accommodate high production rates and high volumes of overspray.

- The water curtain scrubs the air, removing more particles than dry filters alone.

- They produce less back pressure which improves airflow and drying times.

However, water wash booths do come with some downsides as well. The main disadvantage is higher operating costs since energy and water is required to run the water wash system. There is also more maintenance involved with cleaning out the water tank and replacing water filters periodically. The initial purchase price of water wash booths tends to be higher than dry filter booths.

Overall, water wash spray booths offer superior overspray capture for high production shops. They accommodate heavier spraying loads while maintaining good airflow. The water wash is efficient at scrubbing particles out of the air. However, the higher operating costs may make them prohibitive for lower volume shops.

Downdraft Spray Booths

In a downdraft spray booth, air is drawn down from the ceiling through filters and exits through grates in the floor. This downward airflow pulls overspray and contaminants down and out of the booth, which helps keep the interior cleaner (https://www.spraysystems.com/crossdraft-vs-downdraft-paint-booths-which-airflow-design-is-right-for-you/).

Some of the advantages of downdraft spray booths include:

- Cleaner interior since overspray falls straight down

- Less turbulence in the booth which can help improve finish quality

- No back wall to clean since air exits through the floor

Some disadvantages include:

- More expensive to construct since it requires floor grates and excavation

- Limited ventilation since air only enters from the ceiling

- Not suitable for painting large or tall objects

Overall, downdraft spray booths provide very efficient airflow and contaminant control, making them ideal for automotive painting. However, the higher construction costs mean they are better suited for professional body shops rather than small home or hobbyist shops (https://www.usiitalia.com/en/crossflow-downdraft-and-semi-downdraft-spray-booths-pros-and-cons-of-each-type/).

Semi-Downdraft Spray Booths

Semi-downdraft spray booths direct air diagonally downward towards exhaust vents along the sides and back of the booth. The airflow enters from the ceiling and upper side walls at an angle, providing a blend between downdraft and side draft booths.

This semi-downdraft design provides good containment of overspray particles while still allowing some flexibility in terms of object size and shape. The angled airflow helps wrap around objects and prevent backspray onto freshly painted surfaces. It also provides effective filtration compared to crossdraft booths (Crossflow, Downdraft and Semi-Downdraft spray booths – USI ITALIA).

Some of the advantages of semi-downdraft booths include:

- Good overspray containment on all sides of object

- Flexibility for larger items compared to downdraft

- More even airflow distribution than crossdraft

- Effective filtration of particulates

Some potential disadvantages include:

- More expensive than crossdraft booths

- Not as adaptable as side draft booths for very large objects

- Requires more floor space than crossdraft

Overall, semi-downdraft spray booths offer a nice balance between containment, flexibility, and cost. They work well for medium to large production shops painting various object sizes and shapes (Choosing The Right Paint Booth For You – Accudraft).

Side Draft Spray Booths

Side draft spray booths direct airflow from the sides of the booth perpendicularly towards exhaust filters and fans positioned on the opposite wall. This creates a cross-draft airflow pattern inside the booth.

In a side draft booth, the object being painted sits in the middle of the booth while fresh air enters from both sides through inlet filters. The air moves across the object, capturing overspray, before exiting through exhaust filters on the far wall. Downdrafts are minimized since air enters at working level.

Some key advantages of side draft spray booths include:

- Even airflow distribution for consistent paint coverage.

- Minimal downdrafts that can disturb fresh paint.

- Flexible booth sizes and layouts.

- Lower installation costs without need for pits or raised floors.

Potential downsides include more overspray buildup on side walls compared to downdraft designs. Filters may also need more frequent cleaning/replacement [1].

Overall, side draft spray booths offer a versatile and affordable option well-suited for diverse applications from automotive painting to industrial finishing.

Environmental Considerations

Different types of spray booths have varying impacts on the environment. Water wash booths use large amounts of water which needs to be treated before disposal or reuse. The wastewater contains paint solids and other contaminants which can be difficult to remove (https://dec.vermont.gov/sites/dec/files/wmp/HazWaste/Documents/FactSheets/boothfilters_fs.pdf). Dry filter booths produce less wastewater but the filters must be changed regularly and disposed of properly. Incinerating used filters can release emissions into the air.

In terms of air emissions, water wash booths are very effective at capturing overspray particles and minimizing pollution. Dry filter booths allow more particles to escape into the air so they require additional filtration systems. Downdraft and semi-downdraft booths direct contaminated air downwards which helps prevent the spread of overspray but does not eliminate emissions. Proper maintenance and filter change intervals are critical for minimizing environmental impact with any spray booth type (https://zparint.com/how-to-keep-your-spray-booth-eco-friendly/).

Overall, water wash booths generate more liquid waste but lower air emissions compared to dry filter booths. Consider airflow design, filter efficiency, maintenance protocols, and wastewater treatment capabilities when selecting the most environmentally friendly option for a specific application.

Cost Comparisons

When evaluating spray booth costs, it’s important to consider both the upfront costs as well as the long-term operating costs. Here’s a look at the cost ranges for the different types of spray booths:

Dry Filter Spray Booths

Upfront Cost: $5,000 – $15,000

Operating Cost: Lower operating costs since filters only need occasional cleaning/replacement. Energy costs also tend to be lower.

Water Wash Spray Booths

Upfront Cost: $15,000 – $30,000

Operating Cost: Higher operating costs due to water usage for cleaning and waste water disposal. Energy costs can also be higher.

Downdraft Spray Booths

Upfront Cost: $10,000 – $20,000

Operating Cost: Moderate energy and maintenance costs.

Semi-Downdraft Spray Booths

Upfront Cost: $10,000 – $25,000

Operating Cost: Slightly higher energy and maintenance costs than downdraft.

Side Draft Spray Booths

Upfront Cost: $6,000 – $15,000

Operating Cost: Lowest energy costs but filters need frequent replacement.

Best Uses for Each Type

Here’s a summary of which applications each spray booth excels at:

Dry Filter Spray Booths are best for small-scale, intermittent painting jobs of items like auto body parts, furniture, metal products, etc. They are low cost and simple to maintain. The dry filters make cleanup easy.

Water Wash Spray Booths are ideal for high volume, continuous production painting. The water wash system efficiently captures overspray, making them good for painting cars, aerospace parts, appliances, etc. They require more maintenance than dry filters.

Downdraft Spray Booths are optimal when painting large products like boats, cars, machinery, etc. The downward airflow captures overspray efficiently. They take up significant floor space.

Semi-Downdraft Spray Booths offer a hybrid design good for large objects while taking up less space. They aren’t as efficient at overspray capture as full downdraft.

Side Draft Spray Booths are compact and good for long or tall objects like cabinets, doors, pipes, etc. They aren’t suitable for large vehicle painting. Overspray capture is decent but not as good as downdraft.

Conclusion

When looking at the various types of spray booths, there are a few key factors to consider in determining the best option. Dry filter booths are inexpensive and easy to maintain, making them a good choice for small auto body shops on a budget. Water wash booths offer superior filtration capabilities for high production painting, but have higher installation and maintenance costs.

Downdraft booths are ideal for spraying large or awkwardly shaped objects since they pull fumes down and away from the operator. Side draft booths are a great compromise between performance and price. Environmental regulations, production volume, and the types of coatings used should all weigh into the decision making process.

Overall, for a combination of performance, price, and flexibility, a semi-downdraft spray booth is likely the best option for most body shops. Semi-downdraft booths position filters both horizontally and vertically to provide excellent containment of overspray. They pull fumes down and away from the painter’s breathing zone while remaining more affordable than full downdraft or water wash booths. For delivering clean, efficient air flow across diverse painting jobs, semi-downdraft spray booths are a great investment.