What Is The Chemical Formula For Clay?

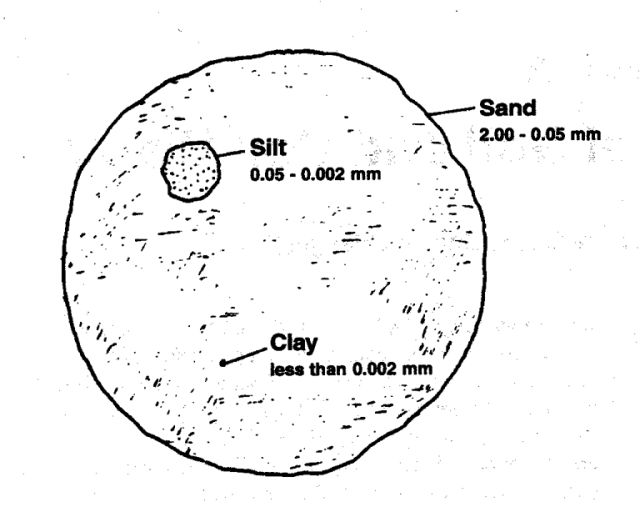

Clay is a fine-grained natural rock or soil material that combines one or more clay minerals with possible traces of metal oxides and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure.

Clays are plastic due to their water content and become hard, brittle, and non–plastic upon drying or firing. Depending on the soil’s content in which it is found, clay can appear in various colors from white to dull grey or brown to deep orange-red.

Chemical Composition

Clay is primarily composed of very small particles derived from the chemical weathering of rocks. The main chemical components that make up the structure of clay are silicon dioxide, aluminum oxide, and water. These three ingredients comprise over 95% of most clay’s chemical composition.

Silicon dioxide (SiO2), sometimes known as silica, is the most abundant chemical compound in clay. It forms a tetrahedral molecular structure that connects with other silica tetrahedrons and aluminum and oxygen atoms to create the crystalline structure of clay particles. Silicon dioxide typically comprises from 40-60% of a clay’s mass.

Aluminum oxide (Al2O3), also called alumina, is the second most common oxide found in clay materials. Aluminum atoms bind with oxygen atoms to form octahedral structures that help stack the silica tetrahedrons. Alumina comprises 10-40% of the mass of most clays.

Water (H2O) is the third primary ingredient of clay. Water molecules connect and surround the silica and alumina structures, influencing the plasticity of the clay. Chemically bonded water usually comprises from 5-10% of a clay’s mass.

Silicon Dioxide

Silicon dioxide, also known as silica, is one of the most abundant chemical compounds found in clay. Its chemical formula is SiO2. In this formula, there is one silicon atom bonded to two oxygen atoms.

Silicon has four electrons in its outer shell that it shares with the oxygen atoms, who each have six outer shell electrons. This allows each silicon atom to form stable covalent bonds with two oxygen atoms, creating an overall neutral compound.

The silica molecule has a tetrahedral structure, with the silicon atom at the center and oxygen atoms at each of the four corners. This geometric arrangement minimizes charge density and creates a very stable molecule. The tetrahedral structure allows silica molecules to form long crystal lattice structures in clays.

Silicon dioxide demonstrates some useful properties in clay. It is hard and resistant to weathering, giving clay strength and structure. However, its crystalline nature also allows silica particles to slide past each other, giving clay its plasticity when wet. Overall, the abundance and properties of silica make it an essential component of clays.

Aluminum Oxide

Aluminum oxide is another major component of clay. It has the chemical formula Al2O3 and is also known as alumina. Alumina has a crystalline structure with layers of aluminum cations and oxygen anions held together via ionic bonding.

Some key properties of aluminum oxide in clay include:

- Acts as a flux, promoting vitrification and lowering the melting point of clay when fired.

- Increases the strength and hardness of clay bodies.

- Adds plasticity and dry strength when raw.

- At high temperatures, alumina promotes glass formation during firing.

The amount of alumina can vary substantially between clay types, but it typically constitutes 15-30% of most clay’s composition. The alumina content has a significant effect on the working properties and fired characteristics of clay. Higher alumina leads to more shrinkage, increased hardness and strength, and higher firing temperatures.

Water

The water in clay plays an important role in its structure and properties. Clays have a layered sheet structure held together by weak electrostatic forces. These sheets are hydrophilic, meaning they can attract and absorb water molecules between the layers. The amount of water absorbed greatly impacts the clay’s plasticity, hardness, strength, shrinkage, and other attributes.

When clay has absorbed the maximum amount of water possible without losing its solid state, it reaches its plastic limit. At this stage the clay is most flexible and moldable. As water content decreases, the clay becomes stiffer and more brittle. The optimal water content depends on the intended use and forming process for the clay.

Water also acts as a lubricant between the clay platelets. It allows them to slide over one another when the clay is shaped. The thickness and viscosity of the water layer influences the clay’s moldability. Clays like bentonite have thin water layers that provide high plasticity. Other clays have thicker water films that reduce plasticity.

The drying and firing processes in clay production also depend on water content. As clay dries, remaining water evaporates and can create shrinkage. The right drying conditions are important to minimize cracking and warping. Similarly, water molecules help transport ions and influence reactions during firing that give clay its hardened ceramic properties.

Other Components

In addition to silicon dioxide, aluminum oxide, and water, clays contain minor amounts of various other elements that influence their properties. Some of the most notable minor components in clay include:

- Iron oxides – These give clay its coloring, ranging from light tans and browns to deeper reds and grays depending on the amount and type of iron present.

- Magnesium – Magnesium ions help give clay its plasticity and increase its strength when fired. Mg-rich clays are valued for pottery.

- Calcium – Calcium promotes flocculation and increases dry strength in clay. However, too much Ca can lead to lime spots.

- Sodium – Sodium ions disperse clay particles and reduce plasticity. Sodium-rich clays are undesirable for most applications.

- Potassium – Like sodium, potassium ions help disperse clay but have less impact on plasticity.

- Titanium – Titanium gives clay a creamy white color and increases refractory properties.

Trace amounts of other elements like manganese, barium, chromium, zinc, and copper can also influence the properties and behavior of clays.

Clay Classification

Clays can be categorized based on their crystal structure and composition. The three main groups of clays are:

- Kaolinite – This clay has a 1:1 crystal structure, meaning it has one tetrahedral sheet linked through oxygen atoms to one octahedral sheet. Kaolinite clays are non-expanding and do not swell with the addition of water.

- Smectite – This group includes montmorillonite clay and has a 2:1 crystal structure. There are two tetrahedral sheets sandwiching one octahedral sheet. Smectite clays are expanding and can swell significantly in the presence of water.

- Illite – This clay has a 2:1 structure similar to smectite but has different interlayer cations that limit swelling. Illite exhibits moderate expanding properties.

The specific crystal structure and expanding capacity of different clays determine their uses. For example, kaolinite is often used in ceramics while bentonite, a smectite clay, is used for its swelling ability to create clay barriers and liners.

Crystal Structure

The crystal structure of clay minerals is comprised of tetrahedral and octahedral sheets. Tetrahedral sheets contain silicon atoms surrounded by four oxygen atoms in a tetrahedral arrangement. These sheets are held together by sharing three oxygens from adjacent tetrahedra. Octahedral sheets contain aluminum or magnesium atoms coordinated by six oxygens or hydroxides in an octahedral arrangement. The octahedral and tetrahedral sheets are stacked on top of each other to form the layered structure characteristic of clay minerals.

There are two main types of crystal structure in clays. In the 1:1 structure, one tetrahedral sheet alternates with one octahedral sheet. In the 2:1 structure, an octahedral sheet is sandwiched between two tetrahedral sheets. Variations in the stacking arrangements and substitutions within the sheets give rise to the wide variety of clay mineral types.

Uses of Clay

Clay has many important uses in various aspects of daily life. Here are some of the main ways that clay is utilized:

Pottery

One of the most well known uses for clay is for making pottery. The natural properties of clay make it an ideal material for shaping and molding into various types of containers, dishes, art objects, and more. Clay’s plasticity allows it to be formed into virtually any shape, while still being durable once fired in a kiln.

Medicine

Clays such as kaolin are used in medicines and pharmaceuticals. The mineral content of clay and its fine particle size allow it to be incorporated into medications for treatment of diarrhea, indigestion, and other digestive issues. Some clays are also used topically for skin conditions due to their absorbent properties.

Construction

Clay in the form of bricks has been a building material for thousands of years. Modern construction also uses clays for making cement and concretes. The hardness and durability of fired clay makes it an important ingredient in creating strong, long-lasting structures.

Conclusion

In summary, clay is an abundant and diverse material composed primarily of silicon dioxide and aluminum oxide along with water and other minor elements. The exact chemical makeup and structure of clay determines its physical properties and how it behaves. This in turn affects what clays are suitable to be used for in different applications.

Understanding the chemistry behind different types of clay is crucial. It allows us to engineer specialized clays with specific properties tailored to their intended use, whether that be in ceramics, construction materials, cosmetics, waste containment, or many other applications. The chemistry and atomic structure of clay gives rise to its incredible versatility and usefulness across so many aspects of everyday life.