What Is The Common Name For Calcium Bentonite?

Calcium bentonite is a clay formed from volcanic ash. It is composed mostly of montmorillonite, a type of phyllosilicate mineral that forms microscopic clay sheets. The term bentonite refers to any clay material composed primarily of montmorillonite. The “calcium” designation indicates it also contains calcium as an exchangeable cation. Calcium bentonite has unique properties and a variety of uses.

Common Name

The common name for calcium bentonite is swelling clay or sodium bentonite. Swelling clay is a more general term that refers to any clay material containing montmorillonite, which has the ability to absorb large amounts of water and expand significantly in volume. Sodium bentonite specifically refers to a clay material containing the mineral montmorillonite, where sodium is the predominant exchangeable cation. The name comes from Fort Benton, Wyoming, where large deposits of this clay were first found by Wilbur C. Knight in 1888. Sodium bentonite is the most commonly used member of the bentonite clay family due to its excellent swelling and adsorption properties, making it ideal for applications such as drilling, binding, sealing, and clarifying (Wikipedia, 2023; BulkNaturalsWholesale, 2023).

Chemical Composition

The chemical composition of calcium bentonite is primarily montmorillonite clay. Montmorillonite is composed of layered sheets of silica and alumina held together by interlayer cations like sodium, calcium, and magnesium [1]. The chemical formula for montmorillonite is Al2O3•4(SiO2)•H2O [2]. Calcium bentonite contains a significant amount of calcium ions, typically over 15%, substituted for aluminum in the montmorillonite structure. This gives calcium bentonite the ability to absorb high amounts of water compared to other clay minerals. The presence of cations like calcium and sodium also allow calcium bentonite to absorb other molecules and ions out of aqueous solutions.

[1] https://www.researchgate.net/figure/Chemical-composition-of-the-calcium-bentonite_tbl1_341852309

[2] https://www.irochemical.com/product-detail/bentonite/

Structure

Calcium bentonite has a layered sheet structure that is held together weakly by van der Waals forces. This unique structure allows calcium bentonite to readily absorb water and swell up to 18 times its dry volume. The individual silicate layers in calcium bentonite are around 1 nanometer thick, with a lateral dimension from several nanometers to several micrometers. When water is absorbed between the layers, they expand in the “c” lattice direction, which allows calcium bentonite to act as an excellent water barrier while still allowing passage of gases and vapors (Wikipedia, Bentonite).

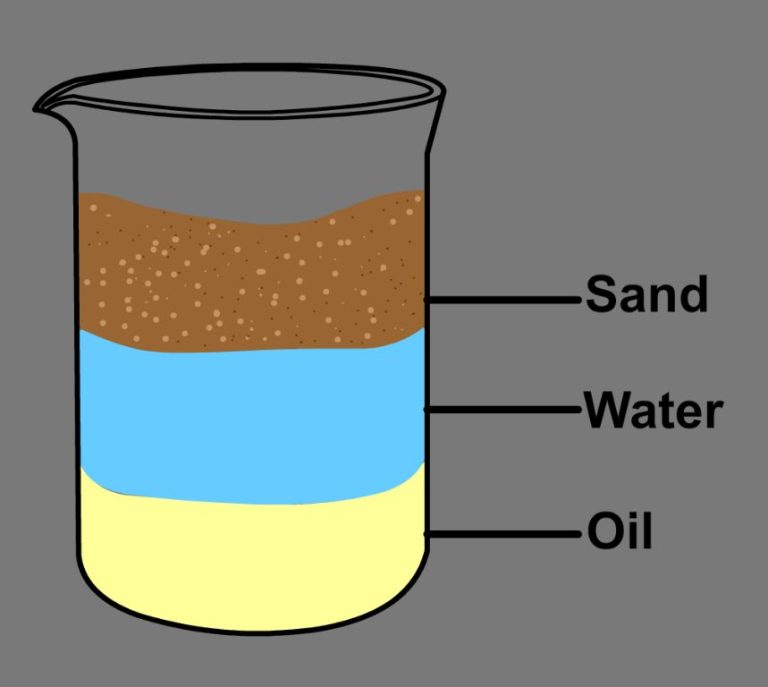

The expandable nature of the layered structure also gives calcium bentonite excellent adsorption and ion exchange properties. It can adsorb ions, as well as fats and oils, within the interlayer spaces. The absorption properties make calcium bentonite useful in a wide variety of industrial applications including drilling fluids, foundry sand binding, wastewater treatment, and more (Irochemical, Bentonite).

Uses

One of the most well known uses of calcium bentonite clay is as a drilling fluid in the process of drilling oil and gas wells. The clay is added to water to create a viscous, shear-thinning fluid called drilling mud. Drilling mud helps lubricate and cool the drill bit, carry rock cuttings to the surface, prevent blowouts by forming a barrier between formation pressures and the wellbore, and form a filter cake lining the wellbore to prevent fluid loss into porous formations. Calcium bentonite is ideal for drilling muds because of its rheological properties as well as its ability to form an impermeable filter cake.

Calcium bentonite is also utilized as a binding agent in products like animal feed and pelletized seeds. The adhesive properties allow fine particles to stick together and form larger pellets or granules. This helps prevent dust and makes the products easier to handle.

Due to its strong absorption and adsorption abilities, calcium bentonite is used as an absorbent material. It can absorb up to seven times its dry weight in water. Some applications include absorbing pet waste, absorbing grease/oils spills, cat litter, wastewater treatment, and absorbing liquid in disposable diapers and feminine hygiene products.

Geological Origins

Bentonite is formed from volcanic ash that fell into ancient seas. The ash underwent chemical changes as it interacted with sea water, which caused the ash to harden into solid rock.

Specifically, bentonite forms from weathering volcanic ash in marine environments. The volcanic ash contained unstable volcanic glass that was rich in silica and alumina. When this ash fell into ancient seawater, it reacted with the seawater and started transforming into clay minerals.

The most important reaction was the alteration of volcanic glass into smectite clays, especially montmorillonite. Montmorillonite is able to absorb large amounts of water, which causes it to expand. The expanding clay filled spaces between particles of volcanic ash and cemented them together to form solid bentonite rock.

Over millions of years, through the continual effects of weathering and interaction with water, bentonite formed into beds and seams within these layers of volcanic ash. It is mined from these concentrated deposits today. The most active early volcanic ash beds which formed bentonite were located around the Pacific Rim, including Japan and Western North America, although deposits occur worldwide.

References:

[1] https://uwaterloo.ca/earth-sciences-museum/resources/detailed-rocks-and-minerals-articles/bentonite-clay

[2] https://en.wikipedia.org/wiki/Bentonite

Locations

Calcium bentonite deposits are found in many locations around the world. According to the Wikipedia article on bentonite, in the United States, calcium bentonite is mined primarily in Mississippi and Alabama. Other countries with significant deposits of calcium bentonite include:

China – China has large reserves of bentonite and is a major global producer. Deposits are found across the country, including in the provinces of Heibei, Inner Mongolia, and Shandong.

Greece – Greece has significant bentonite deposits, particularly calcium bentonite, located in Kimolos and Milos, according to the USGS report on bentonite.

India – Major deposits of bentonite are located in Gujarat, Rajasthan, Tamil Nadu, and other areas of India. Both sodium and calcium bentonite varieties are found.

France – France has deposits of calcium bentonite in the Center-Val de Loire region and around the Mediterranean Sea coast.

Mining

Calcium bentonite is primarily mined from open pits. The bentonite is located by drilling to locate deposits. Once a sufficient deposit is located, the area is mined using large earthmoving equipment to extract the clay. The material is then loaded into trucks and transported to a processing facility.

At processing plants, the bentonite clay is put through several processes to optimize its physical properties for applications. Initially it is crushed and dried. Further processing includes grinding, screening, centrifuging, and classifying the material into different particle sizes. Some calcium bentonite is activated with soda ash to convert it to sodium bentonite. The processing enhances the material’s adsorptive, bonding, and catalytic properties.

The resulting bentonite products are then bagged, transported, and sold for use in industries such as oil, agriculture, construction, and pharmaceuticals. Careful processing and quality control ensures the purity and performance of the calcium bentonite materials.

Environmental Considerations

Proper environmental practices need to be followed when mining and utilizing calcium bentonite to ensure sustainability. Calcium bentonite is generally considered more environmentally friendly compared to sodium bentonite due to lower absorption properties resulting in reduced water contamination risks (Source 1). However, bentonite mining can still impact the environment if not managed carefully.

Key considerations around calcium bentonite mining include preserving topsoil, managing drainage and runoff, dust control, and proper disposal and containment of waste materials. Topsoil removal should be minimized and original contours restored after mining (Source 3). Settling ponds, runoff collection, and using water trucks for dust suppression can help protect water resources and air quality. Waste materials like overburden should be stored securely to avoid pollution.

Overall, with proper practices like soil conservation, water management, and waste containment, calcium bentonite can be extracted and utilized in a sustainable manner, while minimizing environmental impacts.

Conclusion

Calcium bentonite, commonly known as fuller’s earth, is an important clay material composed primarily of montmorillonite. Its ability to absorb liquids, exchange cations, and expand significantly in water make it useful for a wide variety of industrial and consumer applications.

Fuller’s earth has been utilized for centuries to process oils and grease, purify water, and add functional properties to products like cosmetics and cat litter. The absorption and swelling capabilities also give it value as a natural sealant and barrier. While originally obtained only from natural deposits, today calcium bentonite can also be produced synthetically.

With expected growth in industries like oil and gas, wastewater treatment, and consumer products, the applications and demand for fuller’s earth clays will likely continue to expand. At the same time, sustainable mining practices and environmental stewardship will be important to preserve the natural bentonite resources for the future.