What Is The Difference Between Casting Plaster And Plaster Of Paris?

Casting plaster and plaster of Paris are both types of plaster that are commonly used in arts, crafts, and construction applications. Though their names sound similar, they have distinct differences in their properties and intended uses.

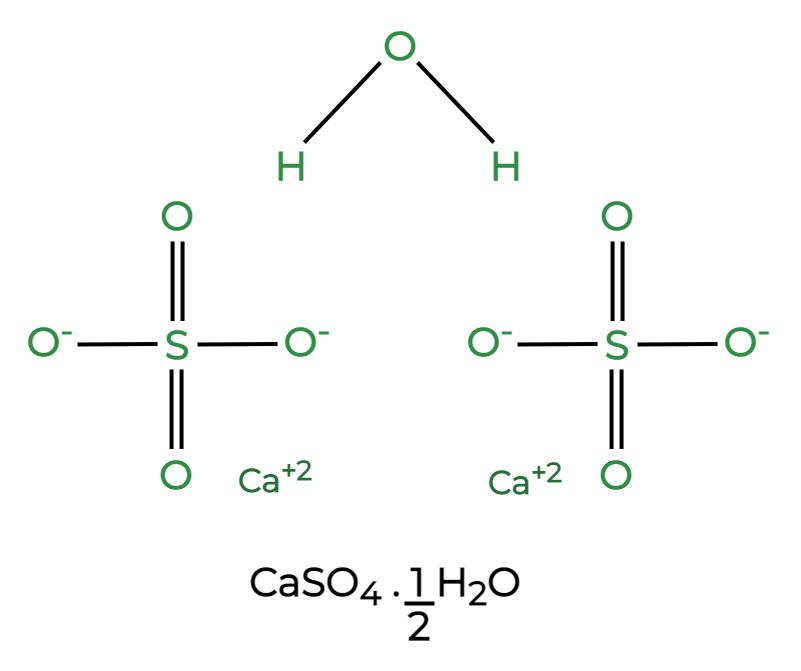

Plaster of Paris, also known as gypsum plaster, is a fine, white powder that is produced by heating gypsum crystals. It is called Plaster of Paris due to its origins in Paris, where it was produced as a powder and shipped around the world in the 1700s.

Casting plaster goes by a few different names including pottery plaster, molding plaster, and dental plaster. It is produced from gypsum rock through a process of crushing, heating and rehydrating the powder.

While both plasters start from gypsum, they undergo different processes resulting in varying levels of hardness, absorbency, and flexibility. These unique characteristics make them suitable for specialized applications ranging from casting molds to medical uses.

Definition of Plaster

Plaster is a building material used for coating walls and ceilings and for molding decorative features. It consists of a mixture of lime, gypsum, sand, and water that hardens into a smooth solid.

The main ingredient in plaster is either gypsum or lime. Gypsum plaster contains gypsum, a soft sulfate mineral that hardens when heated. Lime plaster is made from calcium hydroxide derived from limestone that also hardens through heating.

When mixed with sand, water, and other additives, the gypsum or lime forms a paste that can be molded and spread onto walls and ceilings. As the material dries, chemical reactions cause it to harden, forming a durable surface.

Plaster has been used in construction for centuries. It provides a smooth, durable surface for interior walls and ceilings. It can also be molded into decorative elements like crown molding, ceiling medallions, and ornamental cornices.

Today, plaster is often used in combination with lath, a backing material that provides a binding surface for the plaster. It can be applied in multiple coats to create a solid, uniform surface. The final coat is usually a very fine plaster that produces an exceptionally smooth finish when properly installed.

Plaster of Paris

Plaster of Paris is a type of plaster that is made from calcined gypsum (Plaster of paris | Definition, Uses, & History). It is composed of fine white powder that hardens quickly when mixed with water. The setting time of plaster of Paris is between 5-15 minutes which makes it ideal for casting and molding.

Some key properties of plaster of Paris include:

- Sets and hardens rapidly which allows it to capture fine details of a mold.

- It is dense but still porous which gives good adhesion.

- Has high compressive strength but low tensile strength.

- Shrinks slightly while setting but has low expansion with temperature changes.

- Relatively lightweight compared to other casting materials.

Due to its quick setting properties, plaster of Paris is used for casting molds and models. It can capture fine details before the material sets. The hardness and density allow it to hold shapes while still being workable. Its porosity provides good adhesion with surfaces. Overall, plaster of Paris is an ideal material for casting detailed shapes and molds.

Casting Plaster

Casting plaster, also known as plaster of Paris, is a type of plaster that contains gypsum and clay. The addition of clay prevents the expansion that occurs with pure gypsum plaster, making casting plaster more suitable for taking impressions and making molds (Source: https://www.xometry.com/resources/casting/plaster-casting/).

Casting plaster sets very quickly, usually within 10-15 minutes, which allows molds to be made rapidly. It also has high green strength, meaning it can be handled and worked on shortly after setting. Casting plaster is porous and absorbs water, so molds must be properly sealed before casting liquid material into them. The setting expansion is low at around 0.15% with a dry density of approximately 55 lbs/ft3 (Source: https://en.wikipedia.org/wiki/Plaster_mold_casting).

Overall, casting plaster is ideal for detailed reproduction and mold making because it captures fine details and sets rigidly enough to withstand the casting process. The clay content gives it stability while the fast set time enables efficient workflow.

Key Differences

While plaster of Paris and casting plaster are often used interchangeably, there are some notable differences between the two materials:

| Property | Plaster of Paris | Casting Plaster |

|---|---|---|

| Setting Time | Sets in 10-30 minutes | Slower setting, around 45-60 minutes |

| Strength | Weaker and more porous | Stronger and less porous |

| Expansion | Around 0.2% | Around 0.1% |

| Main Uses | Crafts, sculptures, medics casts | Molds, casting metal, prototypes |

As the table illustrates, casting plaster sets more slowly but results in a stronger, less porous final product. It exhibits less expansion and is preferred for casts that require high durability like metal casting or repetition as it can withstand repeated castings. Plaster of Paris sets faster and is more commonly used for crafting, sculptures and medical casts.

Uses of Plaster of Paris

Plaster of Paris has many uses in various fields including art, dentistry, orthopedics, and construction. Some of the common uses of plaster of Paris are:

- In art, it is used for making sculptures, statues and decorative work. The Venus de Milo statue in the Louvre is made of plaster of Paris.

- In dentistry, it is used to make dental impressions and custom dental devices.

- In orthopedics, it is used to make orthopedic casts and splints to support broken bones while they heal (Housing.com).

- In construction, it is used to provide smooth finishes for walls and ceilings. It can also be used to make architectural moulds.

- It is used to make chalk sticks and modeling clay.

- Plaster of Paris is used to make voussoirs and decorative plasterwork for buildings.

Overall, plaster of Paris is a versatile material used in a variety of applications due to its quick setting time, strength, and smooth finish.

Uses of Casting Plaster

Casting plaster has many uses, but some of the most common are making molds and casts. It is a popular material for mold making because it is inexpensive, easy to use, and can capture fine details. Some common uses of casting plaster for molds and casts include:

Making molds for slip casting pottery and ceramics. The plaster mold absorbs water from the clay slip leaving a hollow pottery shape.

Creating molds for plaster casting sculptures, figurines, and architectural elements. These molds capture intricate sculptural details.

Taking impressions of body parts to make life masks or prosthetic appliances. The mold captures a 3D replica of the body part.

Producing latex molds for mask making, props, and special effects. The latex peels away cleanly from the plaster.

Making food molds for shaped cakes, chocolates, ice, butter, and gelatin. The plaster mold gives shape to the food material.

Casting plaster bandages to make medical orthopedic casts for broken bones. The plaster hardens into a rigid support.

Overall, casting plaster allows creators to repeatedly produce intricate shapes and forms from molds. It has been an essential material for mold making and casting for artistic and industrial applications.

Advantages & Disadvantages

When comparing plaster of Paris and casting plaster, there are some key differences in their advantages and disadvantages:

Plaster of Paris has some notable advantages. It sets quickly, allowing you to complete projects faster. It is also lightweight and fire resistant (1). However, plaster of Paris also has some drawbacks. It is not very durable or resistant to damage. Cracks can develop over time as it dries and contracts (2).

Casting plaster offers greater durability and resistance to cracking versus plaster of Paris. It can withstand higher impacts once fully cured without damage (3). However, casting plaster takes much longer to set and fully harden than plaster of Paris. Projects require more time and patience when using casting plaster (4).

Overall, plaster of Paris offers faster setting time but less durability, while casting plaster provides greater strength once cured but requires more patience during the process. The ideal type of plaster depends on the specific project needs.

(1) https://gharpedia.com/blog/plaster-of-paris-pop-uses-advantages-disadvantages/

(2) https://trimurtiproducts.com/blog/advantages-disadvantages-plaster-paris/

(3) [Cite casting plaster durability source]

(4) [Cite casting plaster slower setting time source]

Buying Guide

When buying plaster of Paris or casting plaster, consider the following tips:

Plaster of Paris can be found at most hardware stores, art supply stores, and online retailers like Amazon and Home Depot. It’s sold as a dry powder ranging from 1 to 25 pound bags. Opt for larger bags for big projects to save money. Store in a sealed container in a cool, dry place.

Casting plaster is available at art supply and hobby stores. Buy small bags unless working on major sculpting or casting projects. Properly stored, casting plaster lasts for years. Keep it sealed and dry. The shelf life is reduced if exposed to moisture or humidity.

For both plasters, carefully follow the label directions when mixing the powder with water. Use clean containers and tools. The ideal consistency is a thick but pourable mixture. Let the plaster fully cure for at least 24 hours before painting or sealing the finished project.

Wear gloves and eye protection when mixing plaster. Work in a well-ventilated area. Clean spills right away to prevent stains. Rinse any plaster from skin immediately.

Conclusion

Plaster of Paris and casting plaster are both plasters made of gypsum that have slightly different properties and uses. The key differences are:

- Plaster of Paris sets much faster, in 10-15 minutes, while casting plaster takes 20-30 minutes to set.

- Plaster of Paris is weaker and more porous while casting plaster is very strong and dense.

- Casting plaster is better for making molds while Plaster of Paris is more commonly used for general plastering and crafting.

- Plaster of Paris can’t withstand heat well but casting plaster is highly heat resistant.

In summary, Plaster of Paris is preferred for plastering and crafts when you need a fast-setting plaster while casting plaster is the best choice for making durable molds and casts thanks to its strength and density. Understanding the differences allows choosing the right plaster for the intended application.