What Is The Main Ingredient In Porcelain?

Porcelain is a ceramic material made by heating various materials, including clay, feldspar, and quartz, to high temperatures. It is known for its hardness, whiteness, translucency, and resistance to chemical attack.

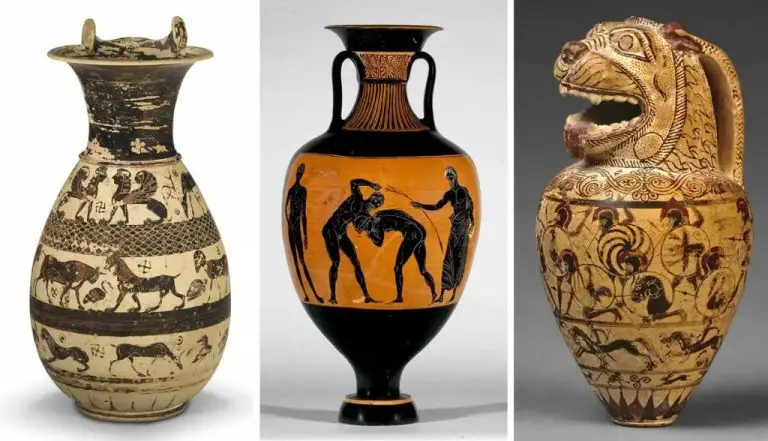

Porcelain has a long history spanning centuries and originating in China. Over time it developed into a highly valued trade good in Europe and around the world. Today it is still widely used for tableware and decorative objects like vases, but also has many industrial applications thanks to its durability and insulating properties.

The key ingredient that gives porcelain its distinctive characteristics is feldspar. Feldspar is a type of mineral that makes up more than half of the earth’s crust. When feldspar is combined with other raw materials and fired at extremely high temperatures, it enables the production of porcelain.

What is Porcelain?

Porcelain is a type of ceramic made by firing materials including clay at very high temperatures between 2,200–2,600°F (1,200–1,430°C) until the clay vitrifies and becomes non-porous. The most common and traditional types of porcelain are bone china, hard-paste porcelain, and soft-paste porcelain. Porcelain is known for being white, translucent, and very hard (Wikipedia, n.d.).

Unlike earthenware and some other ceramic materials, porcelain is impermeable by water and other liquids and not easily scratched or chipped. Due to its beauty, durability, and utility, porcelain has been mass produced worldwide since it was first developed in China during the Tang Dynasty in the 7th century AD (Britannica, n.d.).

The firing process transforms the clay into a material that is dense, hard, and thin (Britannica, n.d.). The finished porcelain product is smooth, white, translucent and resonant to strike. Porcelain’s composition and formation process sets it apart from other types of pottery and ceramics (Merriam-Webster, n.d.).

History of Porcelain

Porcelain originated in China during the Tang dynasty in the 7th century CE. According to the Britannica article on porcelain, early Chinese porcelain wares were created by heating a paste of ground feldspar or kaolin, quartz, and clay at very high temperatures up to 1300–1400°C.[[1]](https://www.britannica.com/art/porcelain)

Production methods were refined over the centuries until true porcelain emerged during the Yuan dynasty in the 13th and 14th centuries. Porcelain production flourished and expanded across China through the Ming and Qing dynasties.

Porcelain was introduced to Europe in the 18th century after being imported from China by the East India Trading Company. The Wikipedia article on porcelain notes that porcelain was initially a luxury item used by the elites and royalty of Europe. [[2]](https://en.wikipedia.org/wiki/Porcelain)

Over time, European potteries developed their own techniques to produce porcelain. By the 19th century, porcelain was widely used for both domestic wares like dishes and cups as well as art objects and technical ceramic parts.

Modern Uses of Porcelain

Porcelain is valued for its strength, durability, whiteness, translucency, and resistance to chemical attack. This makes it an ideal material for a variety of modern applications including:

-

Dishware – Due to its non-porous nature and resistance to scratching, porcelain is highly prized for plates, bowls, cups and other eating and serving vessels. Fine porcelain dishware is a hallmark of elegant dining.

-

Bathroom fixtures – Porcelain’s impermeability makes it an excellent choice for sinks, toilets and tubs. Porcelain bathroom fixtures bring a clean, refined look to bathrooms.

-

Electrical insulators – Porcelain has very high electrical insulation properties. It is commonly used to insulate high voltage cables and electric insulators.

-

Dental implants – The strength, compatibility and aesthetic properties of porcelain make it useful for dental restorations including crowns, bridges and dental implants.

-

Artistic sculptures – Porcelain can be sculpted into delicate, detailed pieces of art. Porcelain’s white color and translucence create a beautiful, decorative medium.

These varied applications highlight porcelain’s uniqueness as a versatile, functional and beautiful material.

Porcelain Composition

Porcelain is composed of three key ingredients: clay, feldspar, and quartz. Feldspar is the most important ingredient that gives porcelain its white color and allows it to be fired at extremely high temperatures to vitrify the clay.

Feldspar acts as a flux, which is a material that liquefies during firing to facilitate vitrification. Vitrification is the process by which the high firing temperature causes the silica in the clay to fuse, becoming fully glassified and non-porous. Feldspar lowers the vitrification temperature of porcelain to between 1,200°C and 1,400°C (2,200°F to 2,600°F).

Specifically, potassium feldspar and sodium feldspar are used in porcelain. Feldspar melts at 115°C-120°C forming a glassy phase that reduces porcelain’s firing temperature and allows the clay particles to bond together. During firing, the potassium, sodium, and aluminum ions in the feldspar react with silica in the clay body to form glass.

Quartz is added to the clay-feldspar mixture to enhance the strength and durability of porcelain. Quartz has a high hardness and withstands thermal shock well. The addition of finely ground quartz particles also aids in controlling shrinkage and reducing cracking during firing.

The combination of these ingredients at the right proportions results in porcelain’s translucent, white, vitrified, and non-porous qualities.

Properties of Feldspar

Feldspar is an aluminosilicate mineral that contains aluminum, silicon, and oxygen. It has many unique properties that make it a vital component in porcelain and ceramic production:

Feldspar has a crystalline structure that allows it to melt at relatively low temperatures. This is crucial, as it allows porcelain and ceramic mixtures to vitrify (become glass-like) at the high temperatures they are fired at. Without feldspar, porcelain and ceramics could not achieve vitrification. As the mixture is fired, the feldspar melts and acts as a flux, flowing between the remaining particles and binding them together.

The vitrified feldspar also gives hardened porcelain and ceramic their strength and durability. Unlike clay alone, vitrified porcelain and ceramic cannot be easily scratched or dissolved in water. The glass-like feldspar binder creates a tough, non-porous material.

Finally, feldspar provides porcelain and ceramics with their characteristic translucent, white color. The absence of iron impurities in feldspar allows porcelain to transmit light rather than absorb it. This gives finished porcelain a luminous, pure aesthetic unmatched by other materials.

Sources:

[Feldspar; the backbone of the ceramic and porcelain industry] (https://www.memr.gov.jo/EBV4.0/Root_Storage/EN/Project/Feldspar.pdf)

[Feldspar] (https://digitalfire.com/material/feldspar)

Other Feldspar Uses

In addition to being the main ingredient in porcelain, feldspar has many other uses in various industries:

Glassmaking – Feldspar is an important ingredient in glassmaking. It acts as a flux, lowering the melting temperature of quartz and helping the glass to form. Feldspar is added to glass batches to enhance the strength, durability, and appearance of the final product. Soda-lime glass, made from soda ash, limestone, and silica sand, accounts for 90% of manufactured glass. The addition of feldspar reduces the glass viscosity and allows a higher output of glass from the furnace. [1]

Fiberglass – Fiberglass is a type of fiber-reinforced plastic where the reinforcement fiber is specifically glass fiber. The glass in fiberglass is most often based on silica but may contain varying amounts of oxides of calcium, magnesium, and sometimes boron. Feldspar is added to the glass formulation to improve the strength and hardness of fiberglass products. Fiberglass is commonly used as a reinforcing agent for many polymer products, including roofing shingles, canoes, water tanks, pipes, cladding panels, and thermal insulation. [2]

Soap – Feldspars are used in the production of soap products. They can act as an abrasive, exfoliant, and filler in bars, powders, creams, gels, and liquid soaps. Feldspar provides additional cleaning properties to soaps and gives an attractive, speckled appearance. In K-type soaps, potassium feldspar is used to supply potassium.

Paint – Powdered feldspar is used in paints as an extender – to increase the brightness and resistance to corrosion and weathering. Due to its hardness, feldspar is an excellent abrasive and is frequently used for scouring solutions and soap.

Sourcing Feldspar

Feldspar is commonly mined from igneous and metamorphic rocks around the world. The main producers of feldspar are Turkey, Italy, and China 1. After mining, the feldspar ore is purified through a flotation process that separates it from other minerals in the rock 2. Turkey produces over 11 million metric tonnes of feldspar each year, followed by India at 4.3 million tonnes. The United States also mines feldspar, with the leading states being California, North Carolina, Oklahoma, South Dakota, and Virginia.

Alternatives

While feldspar is the primary flux used in porcelain, there are some alternatives that can be used to replace or supplement it:

Nepheline syenite is a flux material that contains alkalis and alumina like feldspar, so it can sometimes be used as a substitute in porcelain bodies. According to this source, nepheline syenite contributes high alumina without increasing the thermal expansion coefficient, making it useful for replacing some of the feldspar in porcelain formulations when feldspar is in short supply.

Other fluxes like limestone (calcium carbonate) can also partially replace feldspar to provide CaO while reducing costs. Glassy wastes from industrial processes have been researched as low cost feldspar substitutes containing network-modifying oxides that aid sintering. Sericite, a fine grained mica, can also substitute for feldspar in some porcelain bodies, melting during firing and acting as a flux material.

Conclusion

In conclusion, feldspar plays a vital role as the key ingredient in porcelain. As we’ve explored, feldspar is an essential component that gives porcelain its unique properties. Approximately 50-60% of porcelain’s composition is feldspar, providing the strength, hardness, and ability to withstand high temperatures that porcelain is prized for. Without the inclusion of feldspar, porcelain would not possess the delicate, white, translucent qualities that make it such a desirable material for tableware, sanitary ware, electrical insulators, and other applications. The mineral properties of feldspar enable porcelain to be shaped while wet and fired to a hard, dense ceramic. For these reasons, feldspar remains an indispensable ingredient in the creation of porcelain today, just as it has been for centuries.