What Is The Purpose Of Infrared Pyrometer?

An infrared pyrometer, also known as an infrared thermometer or radiation thermometer, is a device used to remotely measure the temperature of an object’s surface. Infrared pyrometers work by detecting the infrared radiation emitted from an object and converting that radiation into a temperature reading (Wintronics).

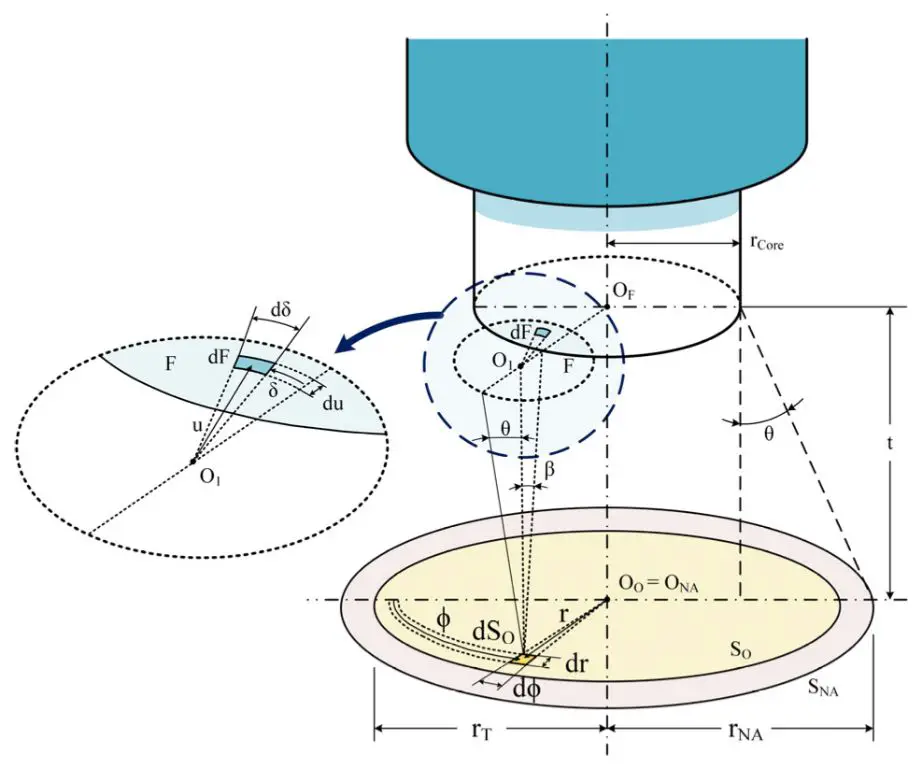

Infrared pyrometers consist of an optical system, a detector, and processing electronics. The optical system focuses the infrared radiation from the target onto the detector, which converts the radiant energy into an electrical signal that can be processed and displayed as a temperature reading. Key components include the lens, which focuses the infrared radiation, and the infrared detector, which is typically a photodetector or thermal detector (Wikipedia).

Infrared pyrometers allow for non-contact temperature measurement, meaning they can measure the temperature of objects or surfaces without needing to physically touch them. This makes them useful for measuring moving objects, hazardous environments, or very hot surfaces.

Measuring Temperature

Infrared pyrometers are devices used to measure the temperature of an object without making physical contact with it. They work by detecting the infrared radiation emitted by the object and converting that radiation into a temperature reading (https://wintron.com/Infrared-Pyrometers-Explained).

The key benefit of infrared pyrometers is that they allow for non-contact temperature measurement. This is advantageous for measuring the temperature of objects that are moving, hazardous, enclosed, or difficult to access physically. By avoiding contact, infrared pyrometers do not interfere with the process being measured or contaminate the target. They can also take measurements very quickly, making them well-suited for monitoring temperatures in real-time processes or during research and testing procedures (https://www.omega.com/en-us/resources/optical-pyrometer).

Principles of Operation

Infrared pyrometers work on the principle that all objects emit heat radiation. The hotter an object is, the more infrared radiation it emits, allowing infrared pyrometers to measure temperature without any contact with the object. This is based on the laws of black body radiation.

Objects emit electromagnetic radiation proportional to their temperature. This radiation occurs over a wide spectrum, but infrared pyrometers are designed to measure wavelengths in the infrared region specifically. The relationship between temperature and radiated energy is described by Planck’s Law.

Infrared pyrometers focus the infrared radiation coming from the target using specially designed lenses. The radiation is transmitted onto an infrared detector, which converts the radiated energy into an electrical signal. Common detector types include thermopile detectors, pyroelectric detectors, and quantum detectors.

By analyzing the strength of the electrical signal, the temperature of the object can be determined. The accuracy depends on having an accurate measurement of the target’s emissivity – how efficiently it emits radiation. Various calibration and compensation techniques are used to account for emissivity.

Overall, infrared pyrometers allow non-contact temperature measurement by detecting the infrared radiation emitted by objects based on the laws of thermal radiation. Optical components focus the radiation onto specialized infrared detectors to generate a signal that corresponds to temperature.

(Sources: https://wintron.com/Infrared-Pyrometers-Explained, https://workswell-thermal-camera.com/infrared-pyrometer/)

Advantages of Infrared Pyrometers

Infrared pyrometers offer several key advantages over contact thermometers that make them an indispensable tool for many applications:

Speed – Infrared pyrometers provide near-instantaneous temperature readings, allowing for real-time process monitoring and control. Contact thermometers require direct contact with the surface being measured, which is often slower. According to Wintron.com, infrared pyrometers can measure temperature in milliseconds or less.

Safety – Since infrared pyrometers are non-contact devices, they can safely measure the temperature of hazardous or hard-to-reach surfaces like fast moving machine parts or extremely hot objects. There is no risk to equipment or personnel.

Consistency – Infrared pyrometers provide consistent, repeatable measurements that are not dependent on the technique of the operator. They eliminate human error and variability.

Cost Savings – Pyrometers can reduce costs by allowing faster monitoring, decreasing downtime, and extending equipment life by enabling predictive maintenance when temperature fluctuations are observed.

Applications

Infrared pyrometers are widely used in many manufacturing and industrial processes to remotely measure temperatures. Some of the most common applications are:

Metal processing – Infrared pyrometers are commonly used in metal processing to measure the temperature in furnaces, ovens, and kilns for annealing, heat treatment, and other high-temperature processes. They allow contactless temperature measurement of moving or inaccessible materials like hot steel or glass (Infrared pyrometers).

Research – Infrared pyrometers are useful scientific tools for materials research and testing. They can measure the temperature of samples during experiments, even at extreme high temperatures above 1000°C. This helps researchers study material properties and behaviors (Infrared Pyrometers Explained – Wintronics).

Manufacturing – Many manufacturing processes rely on precisely controlled temperatures for optimal quality and efficiency. Infrared pyrometers provide non-contact temperature measurement and feedback control in applications like plastic molding, semiconductor processing, and food processing.

Considerations

Infrared pyrometers have some important limitations and considerations to keep in mind. One key limitation is that they do not directly measure temperature, but rather the amount of infrared radiation emitted by an object. This reading must then be converted to a temperature value based on the emissivity of the material being measured, which is not always known accurately (The Limitations of Infrared Thermometers).

Infrared pyrometers can give false readings if the emissivity is not set correctly. Most assume a fixed emissivity that may not match the actual material being measured, leading to incorrect conversions from infrared radiation to temperature (Two Main Limitations of an Infrared Thermometer). Proper calibration and emissivity adjustment is critical for accuracy.

Distance from the target surface is another important factor, as infrared radiation dissipates over distance. Readings need to be taken within the specified working range of the instrument to ensure detection of sufficient infrared radiation.

Infrared thermometers are also limited by their field of view and spot size. They can only measure the temperature of what they are aimed at in their field of view, which may not give the full temperature picture of a larger or irregularly shaped target.

Types

There are several main types of infrared pyrometers:

- Spot pyrometers: These measure the temperature at a single spot or very small area. They are the most common type of infrared pyrometer. Spot sizes can range from less than 1 mm to over 25 mm in diameter depending on the distance to the target.

- Line scanners: These use a linear array of infrared detectors to measure temperatures across a line. They continuously scan across the target surface to create a thermal profile. Line scanners are useful for monitoring hot moving objects like metal strips in a rolling mill.

- Thermal imagers: These use a matrix of infrared detectors (a focal plane array) to create a 2D image showing temperature variations across the target. This allows seeing hot and cold spots across an entire area. Thermal imagers are the most advanced type of infrared pyrometer.

In summary, the main classes of infrared pyrometers are spot types for single point measurement, line scanners for linear profiling, and thermal imagers for 2D thermal mapping. They utilize infrared detectors to remotely measure temperature without contact with the target.

Specifications

Infrared pyrometers have a wide range of technical specifications depending on the model and intended application. Some key specifications to look for include:

Temperature Range: This indicates the minimum and maximum temperatures that can be measured by the pyrometer. Ranges typically span from -50°C to 2000°C or more for high end models. Having a suitable range is important for the target application.

Accuracy: Expressed as a percentage of reading or in degrees Celsius/Fahrenheit. Higher accuracy models can measure within ±0.5°C whereas basic models may be ±2°C or more. Consider the required precision.

Response Time: Indicates how fast the pyrometer can measure a change in temperature. Times range from 5 milliseconds up to 1 second in basic models. Faster response needed for measuring fast processes.

Optical Resolution: Expressed in mm or micrometers. Indicates the minimum spot size that can be measured. Important for small targets or those far away.

Spectral Range: Shows the precise infrared wavelength used for measuring temperature. Typical spectral ranges are 8-14 μm or 7-18 μm. Match spectral range to target material.

Temperature Coefficient: Specifies instrument accuracy error per °C change in ambient temperature. Lower is better for stable readings.

Key specifications should be evaluated against application requirements during selection of the right infrared pyrometer model.

Latest Developments

Infrared pyrometer technology continues to evolve with new innovations and capabilities, giving users more options and flexibility. Some of the latest developments include:

Multispectral pyrometers that can measure multiple wavelengths simultaneously. This allows for temperature measurements of complex surfaces or through flames and exhaust gases [1]. Dual and multi-wavelength pyrometers are gaining popularity as well.

Higher temperature ranges up to 3000°C or beyond through improvements in detector materials and optics [2]. This expands the applications for pyrometers in high-temperature industrial processes.

Faster response times and higher sampling rates to capture rapid temperature changes. Response times under 10 ms are now commonplace.

Advancements in lasers, optics, and electronics are enabling smaller footprint instruments while maintaining excellent performance. Portable and compact pyrometers are ideal for field measurements.

More user-friendly interfaces and communication options through touchscreens, Bluetooth/WiFi connectivity, data logging, and other smart features. This improves ease-of-use and data analysis capabilities.

Overall, the goal of many of these innovations is to provide more flexible, versatile, and high-performance infrared pyrometry solutions to users in a variety of industries and applications.

Conclusion

In summary, infrared pyrometers are devices used to remotely measure the temperature of objects by sensing the infrared radiation they emit. The key purposes of infrared pyrometers are:

- Non-contact temperature measurement – Pyrometers can measure temperature from a distance without contacting the target object.

- High temperature measurement – They can measure very high temperatures beyond the range of thermocouples or RTDs.

- Fast response time – Infrared pyrometers have a very fast response time, providing real-time temperature readings.

- Hazardous environment usage – Pyrometers enable temperature measurement in hazardous or hard-to-reach locations.

Infrared pyrometers have become indispensable tools in many industrial applications thanks to these capabilities. With ongoing improvements in infrared detector technology and optics, pyrometers are becoming even more precise and reliable for critical temperature monitoring and control.