What Kind Of Drill Bit Do You Need To Make Recessed Holes?

Recessed holes are holes with a shallow recess around the top surface. The recess creates a pocket that allows the head of a bolt or screw to sit flush or below the surface of the material. This is useful for applications where you don’t want the fastener head protruding out. Recessed holes provide a smooth, flat surface and prevent catching on objects.

The most common types of drill bits capable of making recessed holes are Forstner bits, spade bits, hole saws, counterbore bits, and recessed hole cutters. Each has unique properties suitable for particular applications. The choice depends on factors like hole size, depth, precision, and material being drilled. Proper technique and drill speed are also critical for high quality recessed holes.

Forstner Bits

Forstner bits are a type of drill bit that excel at producing clean, flat-bottomed holes with a finishing cut (Forstner Bits – Drill Bits). The cutting edges of a Forstner bit extend all the way to the outer perimeter, allowing the bit to carve out a precise circle with a flat bottom.

Unlike twist drill bits that scrape along the sides of a hole, Forstner bits use radial cutting edges to shear through the material. This results in cleaner edges with no tear out. The flat tip of the drill bit also prevents wandering and slipping that can occur with spade bits or brad point bits.

Forstner bits are guided by the rim and cut the circumference of the hole first before shearing the core at the bottom. They require less axial pressure than other drill bits. They also work exceptionally well in softwood, hardwood, plywood and other man-made boards (Forstner Drill Bits).

Key features of Forstner bits:

- Flat-bottomed holes with clean 90 degree edges

- Minimal tear out

- Clean exit holes

- Precise diameter control

- Efficient cutting in wood materials

Spade Bits

Spade bits are a type of drill bit with a flat, spade-shaped cutting tip designed specifically for drilling holes in wood (Source). They are ideal for making relatively large holes and recessed pockets quickly in wood. The flat tip of the spade bit slices the wood fibers cleanly as it cuts, creating a clean hole with flat edges.

Spade bits can be used to drill counterbored holes for flush mounting screws and creating recessed areas to hide bolt heads. They excel at making clean, flat-bottomed holes with 90 degree edges. Spade bits with a center point can drill through wood without requiring a pilot hole first.

The main advantages of spade bits for making recessed holes are their speed, ability to create flat-bottomed recesses, and clean cut edges. They can drill deep recesses faster than a forstner bit. The main disadvantages are the relatively rough hole edges and potential for splintering around the top edges if not carefully aligned.

Hole Saw Bits

Hole saw bits, also known as hole cutter bits, are drill bits designed to cut very large diameter holes by using a hole saw attachment and an arbor that attaches to your drill. Unlike regular twist drill bits that cut out a cylinder of material, hole saws cut out a full circle by using a circular toothed blade (source: Home Depot).

To use a hole saw, you first need to drill a pilot hole using a standard drill bit. The hole saw arbor has a drill bit tip on it that fits into the pilot hole. As you drill, the hole saw teeth will cut into the material in a circular pattern around the pilot hole to create a large, clean hole. Hole saws come in different diameters, typically ranging from 1/4″ to 6″ or more, enabling you to cut a variety of hole sizes (source: Lowe’s).

The key features of hole saw bits include the cutting diameter, material type (bi-metal or carbide), number of teeth, arbor size, and depth of cut. Make sure to select the appropriate size hole saw for your needs and material you are drilling into. Hole saws with more teeth will cut faster and smoother than those with fewer teeth.

Counterbore Bits

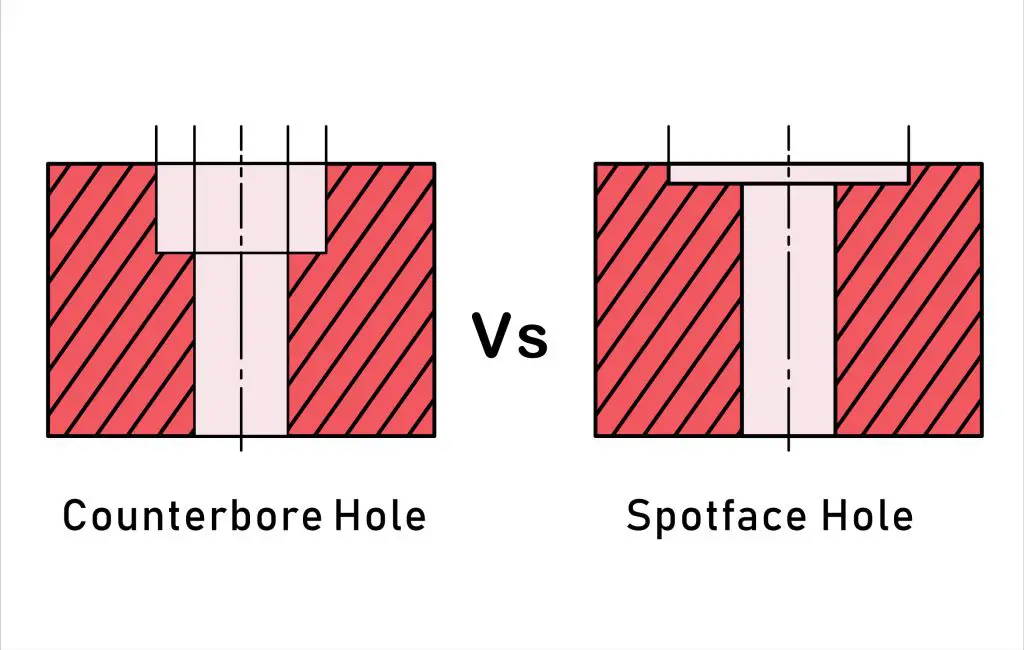

Counterbore bits are specifically designed to create recessed holes with a smaller hole at the bottom. They consist of a pilot bit at the tip to drill the smaller hole, with a counterbore cutter above it to cut the outer recess of the hole. The recess allows a screw head or bolt to sit flush with the surface. Counterbore bits excel at making holes for counter sunk screws and bolts in materials like wood and plastic. They come in sizes matched to common screw sizes so the head can sit flush within the recessed area.

Counterbore bits create clean, accurate recesses for hardware in one step. They are easy to use and make quick work out of creating polished recessed holes for a flush fit. They are ideal for situations where the hardware needs to sit flush without any part sticking above the surface. This gives a smooth finished look. Using a counterbore bit ensures the recess is the proper size and depth for the hardware1.

Recessed Hole Cutters

Recessed hole cutter bits, also known as recessed lighting hole saws, are a specialized type of hole saw designed specifically for cutting holes to install recessed lighting fixtures. These bits allow for quick, clean holes for can lights and other recessed fixtures. According to Lowe’s, the hole cutter’s cup shape and sharp teeth are engineered to extract drywall plugs and minimize dust.

Recessed hole cutter bits come in a range of sizes from 3 to 8 inches to accommodate various sized recessed lighting cans. They usually include a pilot drill bit in the center to keep the hole saw steady and centered while cutting the hole. The Milwaukee 6-3/8 in. Carbide Recessed Light Hole Saw, for example, features carbide grit teeth for increased speed and life when cutting through drywall. Using the right sized bit for the lighting fixture is important for a secure fit.

When using a recessed lighting hole saw, go slowly to avoid tearing the drywall. Let the tool do the work. Apply light pressure and avoid pushing too hard. Follow any directions included with the specific bit for best results. Cutting a hole for a recessed light fixture is usually a quick and relatively simple process with the proper recessed hole cutter bit.

Choosing the Right Bit

When choosing a drill bit, there are several factors to consider:

- Material – Bits designed for metal, wood, concrete etc. Specialty bits for tiles, glass, plastics.

- Hole size and depth – Match the bit diameter to the desired hole size. Longer bits for deeper holes.

- Quality and cost – More expensive bits made of high-speed steel generally last longer than basic carbon steel.

Here’s a comparison of common drill bits for different materials:

| Material | Bit Type | Features |

|---|---|---|

| Wood | Brad point | Clean holes with precise edge in wood |

| Wood | Spade | General purpose drilling in wood |

| Metal | Cobalt or Titanium | Withstand high temperatures when drilling metal |

| Masonry | Masonry | Carbide tip for drilling concrete and brick |

Consult manufacturers’ guidelines and choose the appropriate bit for your project based on the material, desired hole size, depth, quality and budget.

Using the Drill Bit

When drilling a recessed hole, it’s important to follow some best practices to get clean, accurate results:

- Drill at an appropriate speed – for larger Forstner, spade, and hole saw bits, a lower speed around 800 RPM is best. Go with a higher 1200+ RPM for smaller bits.

- Apply firm, steady pressure – don’t push too hard or the bit may bind up and slip. But adequate downward force keeps the bit cutting efficiently.

- Back the bit out regularly to clear chips – drilling generates a lot of debris, so pull the bit up every 1/4 to 1/2 inch to let the chips clear out of the hole.

- Secure the workpiece – use clamps or a vise to prevent the material from spinning.

- Drill straight down – don’t wobble the bit or angle it. Keep the drill lined up vertically for clean, accurate sides.

- Use a backer board beneath thin material – this prevents splintering as the bit exits the bottom surface.

- Go slowly at end of hole – ease up on pressure and speed to avoid tear out when breaking through the bottom.

- Sharpen bits regularly – dull cutting edges require more force and generate excess heat.

Following these guidelines will result in smooth, splinter-free recessed holes with minimal effort. Allowing the drill bit to work efficiently is key to quality results.

Common Problems

When drilling recessed holes, some common problems that can occur include:

Tear out – This is when the drill grabs the edges of the hole and rips out chunks of material. To prevent tear out, make sure to back the drill bit out repeatedly to clear chips. You can also use a sacrificial backer board underneath the hole. According to 12 common drilling problems and how to avoid them, tear out usually happens on the exit side of a hole.

Uneven holes – If the drill bit is dull or not held perpendicular to the surface, it can make the hole uneven. To fix this, sharpen the bit and use a drill press or guide to keep the bit straight.

Overheating – Friction from dull bits or too much pressure can cause overheating. Let the bit and material cool periodically. Lubricating the bit can also help prevent overheating, per this Reddit comment.

Other issues like drill bit breakage, slippage, or oversized holes can also happen. In general, use sharp bits, secure the workpiece, apply even pressure, and extract the bit regularly.

Conclusion

When you need to drill recessed holes, using the right drill bit is essential. The main types that allow you to create recessed holes are Forstner bits, spade bits, hole saws, counterbore bits, and recessed hole cutters. Each has their particular advantages and best uses.

Forstner bits cut precise, flat-bottomed holes and are ideal for drilling into wood. Spade bits are affordable and can drill large diameter recessed holes in wood. Hole saws allow you to cut very clean circular recesses, but work better in softer materials. Counterbore bits are specifically designed for recessed holes when using screws. Finally, recessed hole cutters create clean, accurate recesses for hardware in materials like wood, plastic and light metal.

Consider the size of hole, depth, material you’re drilling into, and your budget when selecting the right bit. Use proper speeds, pressure and drilling technique for clean results. With the right drill bit, you can create recessed holes for hardware, shelves, cabinets and more.