What Material Is Earthenware?

What is Earthenware?

Earthenware refers to pottery made from clay and fired at low temperatures, typically between 1000-1200°C. The key property of earthenware is that it is porous and permeable to liquids.

Earthenware has a long history dating back thousands of years. Some of the earliest known examples come from China and date back to around 6000 BC 1. In early history, earthenware was used to produce basic utilitarian items like cooking pots, jars, and bowls. It was one of the earliest types of pottery developed across many cultures.

Today, earthenware has many uses. It is frequently used in decoration and art pieces thanks to its ability to be molded into various shapes. Some common types of decorative earthenware include majolica, Delftware, creamware, and terra cotta. Earthenware is also still used to produce baking and cooking dishes due to its heat resistance. However, it is unsuitable for items that will contain liquids due to its porosity.

The key properties that distinguish earthenware are its porousness, low firing temperature, and reddish-orange color after firing. It can be easily scratched with a knife or metal tool. These traits contrast with materials like stoneware and porcelain, which are denser, non-porous, and fire at higher temperatures.

Clay Composition

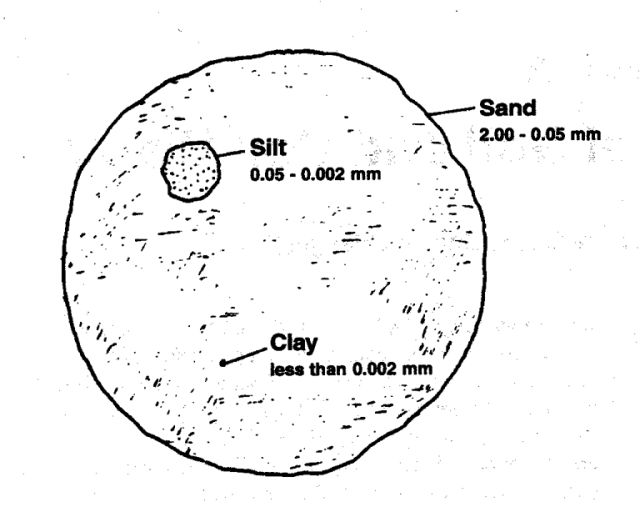

Earthenware clay bodies are typically made from secondary clays like ball clays, fire clays, and kaolin. These clays contain a mix of clay minerals like kaolinite, illite, and montmorillonite that provide plasticity and strength when fired.1 To temper the clay and reduce shrinkage, non-plastic materials like sand, crushed fired clay (grog), or organic material like straw are added as fillers. The composition affects the fired characteristics – higher clay content results in more shrinkage and a denser body after firing. More grog creates an open, porous body that is less prone to cracking and thermal shock.

Manufacturing Process

Earthenware is made from clay that is shaped into forms either by handbuilding techniques or on the potter’s wheel, then dried and fired at temperatures between 900°C and 1,150°C (1,650°F and 2,100°F).

Handbuilding techniques involve shaping the clay by hand without the use of a potter’s wheel. Methods include pinch pots, coil building, and slab construction. With pinch pots, the clay is pinched and pulled into shape. For coil building, ropes of clay are rolled and then stacked or joined together. Slab construction involves rolling out flat sheets or slabs of clay that are cut into shapes and joined.

Wheel throwing involves centering a lump of clay on a potter’s wheel and using hands and tools to shape it while the wheel spins. This allows for symmetrical shapes and thinner walls compared to handbuilding. Skilled potters can create a wide variety of forms on the wheel (Home Stratosphere).

Once shaped, the clay must dry slowly and evenly to avoid cracking before firing. Firing permanently hardens the clay through sintering and can take 12-48 hours at peak temperatures. Temperatures typically range between 900°C and 1,150°C (1,650°F and 2,100°F) for earthenware. Higher temperatures result in greater strength.

Glazes provide color and surface finishes. Glazes are made of minerals that melt and fuse to the clay surface during firing. Glazes may be applied before or after first firing. Popular techniques include dipping, pouring, brushing, and spraying the glaze onto the surface.

Physical Properties

Earthenware is known for its porous physical properties. Due to its chemical makeup and how it is fired, earthenware retains tiny air pockets and bubbles within the clay making it porous. This gives earthenware a few key physical characteristics:

Porosity: The air pockets within the clay make earthenware permeable, allowing air, water and other liquids to seep through the unglazed portions of the ceramic. This porosity makes earthenware less than ideal for uses like liquid containment unless the piece is fully glazed.

Strength: The porous nature of earthenware results in a more brittle and fragile structure than other ceramics like stoneware. It has relatively low strength compared to other ceramics.

Thermal shock resistance: The porous structure also impacts the thermal shock resistance. Earthenware’s high porosity means it retains heat and absorbs temperature changes less evenly. This makes earthenware prone to cracking or breaking when subjected to sudden temperature changes.

Absorbency: The pores give earthenware excellent absorbent properties. Unglazed earthenware readily absorbs water and other liquids. This made it ideal historically for applications like water jugs.

Types of Earthenware

There are several distinct types of earthenware pottery, each with their own characteristics:

Terracotta refers to unglazed or unenameled earthenware clay with an orange-red color. The red color comes from iron oxide contained in the clay. Terracotta has been used for pottery and construction since ancient times. Examples include flower pots, roof and floor tiles, and decorative vases and urns [1].

Redware is a type of unglazed earthenware made from red firing clays. It is similar to terracotta but encompasses other red-hued earthenware like buffware. Redware was widely produced in early America for utilitarian and decorative purposes. It remains popular for flower pots, pitchers, and rustic tableware [2].

Buffware refers to unglazed red earthenware that fires to a light pink or buff color, due to lower iron content. It was often used for cheaper versions of redware pottery items.

Tin-glazed earthenware, also called majolica or delftware, has a white glaze with decorative colorful designs applied on top. The glaze contains tin oxide which gives it a bright white, opaque appearance. Popular for tableware and tiles since the Renaissance.

Yellowware is a type of lead-glazed earthenware with a bright yellow color. It was developed in England in the 1700s and widely used for kitchenware and tableware items before the popularity of white ironstone china.

Notable Earthenware Examples

Some of the most famous and notable examples of earthenware come from various periods throughout history. These include:

Greek Terracottas – Terracotta figurines and reliefs were commonly produced in ancient Greece from the Archaic period onward. These were often religious in nature, depicting deities, heroes, and mythological scenes. Famous examples include the Tanagra figurines.

Medieval Jugs – During the medieval period in Europe, utilitarian earthenware jugs were produced in large quantities for everyday use. These often feature simple geometric or linear decoration. Medieval jugs have been found at archaeological sites across Europe.

Delftware – Originating in the Netherlands in the 17th century, Delftware refers to tin-glazed earthenware often hand-painted with decorative blue designs. Delftware was both an art form and an important export product for the Dutch Golden Age.

Mimbres Bowls – The Mimbres people of the American Southwest adorned bowls with stylized figures of animals, people, and geometric designs. These black-on-white bowls from c. 1000-1150 CE are considered remarkable examples of Native American pottery.

Staffordshire Figurines – Mass-produced earthenware figurines of popular characters, animals, buildings, and other subjects were made in Staffordshire, England from the 18th to 20th centuries. Their designs reflect pop culture trends over time.

Decorative Techniques

Earthenware can be decorated in various ways to enhance its appearance and value. Some common decorative techniques used on earthenware include:

Glazes: Vitreous coatings applied to the surface of fired clay to create a glossy or matte finish and add color. Glazes are made from powdered minerals mixed with water and can come in solid colors, gradients, crystals, and more. They melt and fuse to the clay body during firing. Popular glazes for earthenware include lead glazes and alkaline glazes.

Slips: Made from clay mixed with water to a creamy consistency, slips provide background colors and effects. They can be painted on leather-hard unfired clay. Different colored slips are sometimes layered to create patterns. Slips melt at lower temperatures than glazes.

Sgraffito: Applying layers of contrasting colored slips then scratching through them with tools to reveal the underlying layers in detailed patterns and drawings. It creates decorative lines and textures.

Mishima: Using white or light colored slip to draw fine lines and intricate patterns on a dark background slip. The surface is then scraped or carved away to form a design.

Sprigging: Applying molded or sculpted clay ornamentation and appliques to the surface using slip as an adhesive before firing. Sprigging adds 3D decorative elements.

These and other techniques add visual interest to earthenware pottery. Decorations showcase additional artistic skills and mastery of ceramic methods.[1]

Care and Maintenance

Proper care and maintenance is important for preserving earthenware and extending its lifespan. Here are some tips for cleaning, storing, displaying, and repairing earthenware:

Cleaning Methods

Avoid using harsh abrasives or cleaners on earthenware, as they can damage the porous surface. Instead, wash gently by hand using a soft cloth or sponge with warm water and mild dish soap. Make sure to rinse thoroughly and dry completely. Avoid soaking earthenware and never put it in the dishwasher, microwave, or oven, as rapid temperature changes can cause cracking (1).

Storing and Displaying

Store earthenware in a cool, dry place away from direct sunlight to prevent fading. Use felt pads on the bottom of pieces to prevent scratches. When displaying earthenware, avoid placing in direct sunlight or areas prone to rapid temperature fluctuations. Allow proper ventilation between pieces (2).

Repairing Chips and Cracks

Minor chips can be smoothed and polished with fine grit sandpaper. For hairline cracks, use cyanoacrylate glue like Super Glue. For larger cracks and breaks, epoxy putty specifically formulated for ceramics and pottery works well. Be sure to follow package directions closely. Severely damaged pieces may need professional restoration.

Notable Earthenware Artists

Some of the most famous and influential earthenware artists through history include:

Bernard Palissy (c.1510-1590) was a French potter best known for developing colored lead glazes and unique figural vessels modeled after snakes, fish, and reptiles. He is considered one of the most significant ceramic artists of the 16th century and helped establish France as a major center for ceramics. Encyclopedia Brittanica

Josiah Wedgwood (1730-1795) was an English potter who founded the Wedgwood company, which mass-produced refined earthenware for the emerging middle class market. He perfected cream-colored earthenware, known as Queen’s Ware, and his elegant neoclassical designs were widely copied. Wedgwood is credited with industrializing the manufacture of pottery and making it fashionable. Encyclopedia Brittanica

Maria Martinez (1887-1980) was a Pueblo Indian potter from San Ildefonso, New Mexico known for developing black-on-black pottery with matte black finish. She helped revive traditional Native American pottery methods and aesthetics, making them appealing to modern audiences. Her work is characterized by precisely painted geometric and natural designs.

Shoji Hamada (1894-1978) was a Japanese potter who combined traditional Japanese wares with modern designs inspired by ancient Chinese ceramics. With his student, Bernard Leach, he established the influential Leach Pottery in England which spearheaded the 20th century studio pottery movement. Hamada is renowned for his stoneware vessels with natural ash glazes.

Significance and Legacy

Earthenware has an important cultural heritage and archaeological value. It has been produced by human cultures across the globe for thousands of years, with artifacts dating back to as early as 29,000–25,000 BCE found in China https://www.theedadvocate.org/teaching-students-about-earthenware/. Earthenware provides archaeologists insights into early human civilizations. The study of ancient pottery and ceramics reveals information about the lifestyles, beliefs, and practices of our ancestors.

Despite the development of more advanced ceramics like stoneware and porcelain, earthenware continues to maintain popularity today. Many cultures around the world still use traditional earthenware for cooking, storage, and decoration https://mitticool.com/types-of-earthenware-for-home/. Its porous nature makes it effective for cooling water in hot climates. Compared to stoneware and porcelain, earthenware is less expensive and requires lower firing temperatures. It provides an accessible option for artists and hobbyists to create pottery and ceramic pieces without the need for specialized equipment. After thousands of years, earthenware persists as a practical, decorative, and culturally significant material.