What Motor Is Best For A Pottery Wheel?

Choosing the right motor for a pottery wheel is an important decision that impacts the wheel’s performance and the potter’s experience. Key factors to consider when selecting a pottery wheel motor include power, speed control, noise level, maintenance needs, and cost. The motor largely determines the wheel’s capacity to center clay and maintain speed during throwing. More powerful motors can handle larger loads and throw thicker vessels. Variable speed control allows adjusting the wheel’s speed for different techniques and types of clay. Quieter motors create a more pleasant studio environment. Maintenance needs vary between motors, with some requiring more frequent oiling or cleaning. And cost is always a concern, with more expensive motors offering greater power and features. This guide examines the advantages and disadvantages of different pottery wheel motor types to help buyers choose the best option for their needs and budget.

Power

The power of a pottery wheel motor is an important factor to consider when selecting the right one. Most potters recommend a minimum power of 1/4 horsepower (around 200 watts) for throwing utility ware and simple shapes [1]. For more advanced throwing with larger amounts of clay, a 1/2 to 1 horsepower motor (400-750 watts) allows sufficient torque and speed control [2].

Wheels with lower power ratings under 1/4 horsepower tend to have difficulty centering and driving heavier loads of clay. Their maximum throwing capacity is lower. More powerful motors above 1 horsepower are an option for production potters working very large quantities of clay. However, most hobbyists and art studio potters do not require that much power.

Overall, look for a minimum of 1/4 horsepower motor for a pottery wheel. 1/2 to 3/4 horsepower offers the best balance of power and control for most needs. Go above 1 horsepower only if regularly throwing very large amounts of clay.

Speed Control

Variable speed control is one of the most important features to look for when selecting a motor for a pottery wheel. The ability to adjust the rotational speed allows potters to smoothly center and shape clay, preventing the work from becoming distorted or flying off the wheel.

As the article on PracticalMachinist.com explains, potters need to start slowly and increase the wheel speed as the clay takes shape (Source). Starting too fast can cause an uneven lump of clay to wobble and crack. Variable speed motors allow potters to fine tune the exact speed needed for each stage of the process.

According to Skutt, consistency in wheel speed is also key when centering large amounts of clay or applying pressure while throwing. Their IR Comp controller aims to provide constant speed despite resistance from the clay (Source). This prevents slowdowns that could deform the artwork.

Overall, variable speed is considered essential for pottery wheel motors. It enables the clay work to progress smoothly without defects.

Noise Level

The noise level produced by a motor is an important consideration, as pottery wheels often operate in home or studio environments where lower noise is desired. In general, induction motors tend to be quieter than universal brushed DC motors.

Three-phase AC induction motors produce the least noise and vibration because they lack a commutator and brushes. As noted in a Quora article, the smooth rotating magnetic field in an induction motor results in low mechanical noise.

Research by Gonzalez et al. in Noise in Electric Motors: A Comprehensive Review showed two-speed three-phase induction motors produce lower audible noise levels than other motor types. Meanwhile, a study by Belmans et al. in the IEEE Transactions on Industrial Electronics found inverter-driven induction motors were quieter than comparable DC commutator motors.

Overall, three-phase induction motors are the quietest choice, while universal brushed DC motors tend to have more noticeable humming and vibration. When sound levels are a key factor, induction motors are preferable for pottery wheel applications.

Maintenance

The maintenance requirements of AC motors versus DC motors can vary significantly. According to The Difference Between AC and DC Motors, brushed DC motors usually require much more maintenance and have a shorter lifespan than AC motors. The brushes on DC motors that press against the commutator wear out over time and require replacement.

In comparison, AC motors like induction motors have no brushes and the maintenance is primarily related to bearing lubrication. As noted by What Is the Difference Between AC Motors and DC Motors?, AC motors and brushless DC motors need less maintenance overall and have longer operating lives than brushed DC motors.

The brushless design of AC induction motors makes them more suitable for manufacturing settings where minimal maintenance downtime is desired. Brushed DC motors, while sometimes more efficient, have higher maintenance costs due to more frequent brush replacements.

Cost

When considering motors for a pottery wheel, cost is an important factor. Budget motors typically range from $200-$400. Here are some budget-friendly motor recommendations:

The MH-121T motor from Brent is a good option under $300. It offers 1/2 hp and variable speed control. Though not as powerful as pricier motors, it provides sufficient power for most beginner to intermediate pottery work. (https://thepotterywheel.com/how-much-does-a-pottery-wheel-cost/)

Another budget motor choice is the Powermatic 3520B. It costs around $350 but has a 1 hp motor. This gives it more power for throwing larger pieces of clay. While not packed with features, it is a durable and reliable motor. (https://ceramic.school/how-much-does-a-pottery-wheel-cost/)

On the lower end, the Brent CXC pottery wheel sells for $200-$250 and has a 1/2 hp motor. It’s a lightweight, portable model good for beginners. The motor isn’t very powerful but adequately spins most clay projects. (https://www.theceramicshop.com/store/department/28/wheels/)

Motor Types

There are three main types of motors used for pottery wheels: induction motors, DC motors, and AC motors. Each has its own advantages and disadvantages.

Induction motors are a type of AC motor and one of the most commonly used for pottery wheels. They are relatively inexpensive, efficient, and require little maintenance since they have no brushes. The downside is they can be noisy and don’t offer precise speed control (source).

DC motors provide very smooth operation and excellent speed control. They are often preferred for pottery wheels because speed can be easily adjusted with a foot pedal. However, they do require more maintenance than AC motors since they have brushes that wear out over time. DC motors are also less energy efficient (source).

AC motors have the advantage of being very rugged and low maintenance compared to DC motors. However, they do not offer as precise speed control. Single phase AC motors may also produce more vibrations. Overall, AC motors are simple, durable, and cost-effective (source).

Brands

When it comes to pottery wheel motors, there are several major brands that consistently receive top reviews. These include Brent, Shimpo, Skutt, Soldner, and Speedball.

Brent wheels are known for their power, versatility, and accessibility features. The Brent CXC wheel is popular for its balance of power and control, while their Model B is designed specifically for wheelchair accessibility. Brent motors tend to be on the quieter side while still offering plenty of torque.

Shimpo motors provide a lot of power paired with precise speed control. Their top of the line Whisper wheels offer an extremely smooth, quiet experience. Shimpo is also known for responsiveness and ease of use. The RK-551 model is a favorite for professional ceramic artists.

Skutt motors emphasize user-friendliness and reliability at an affordable price point. The KilnMaster and Prodigy wheels are well-suited for beginners but also provide enough power for intermediate potters. Skutt offers a range of motor sizes to match needs and budgets.

Soldner motors are known for unparalleled power and durability. Their professional wheels like the Soldner TE503 provide industrical strength while maintaining fine speed control. Soldner motors are built to handle continous heavy usage.

Speedball Artista pottery wheels provide a nice balance of value and quality for beginner to intermediate potters. The motors offer smooth variable speed control. Speedball is a trusted American brand that produces accessible, user-friendly wheels.

Researching reviews of the most recommended motors within your budget is wise when selecting a pottery wheel brand. Consider power, noise, speed control, and durability based on your current skill level and projected usage.

Installation

Installing a replacement pottery wheel motor requires some mechanical skills and the right tools, but can be done by an experienced DIYer. The basic steps are:

1. Remove the old motor by unscrewing it from the base and detaching any belts or pulleys connecting it to the wheel head. Refer to the manufacturer’s instructions if available.

2. Mount the new motor securely to the base according to the specific motor’s mounting instructions. Use the proper bolts/hardware and make sure it is stable.

3. Reconnect the drive belt and any pulleys to transfer power from the motor to the wheel head. Adjust the belt tension as needed. Test spin the motor to ensure proper alignment.

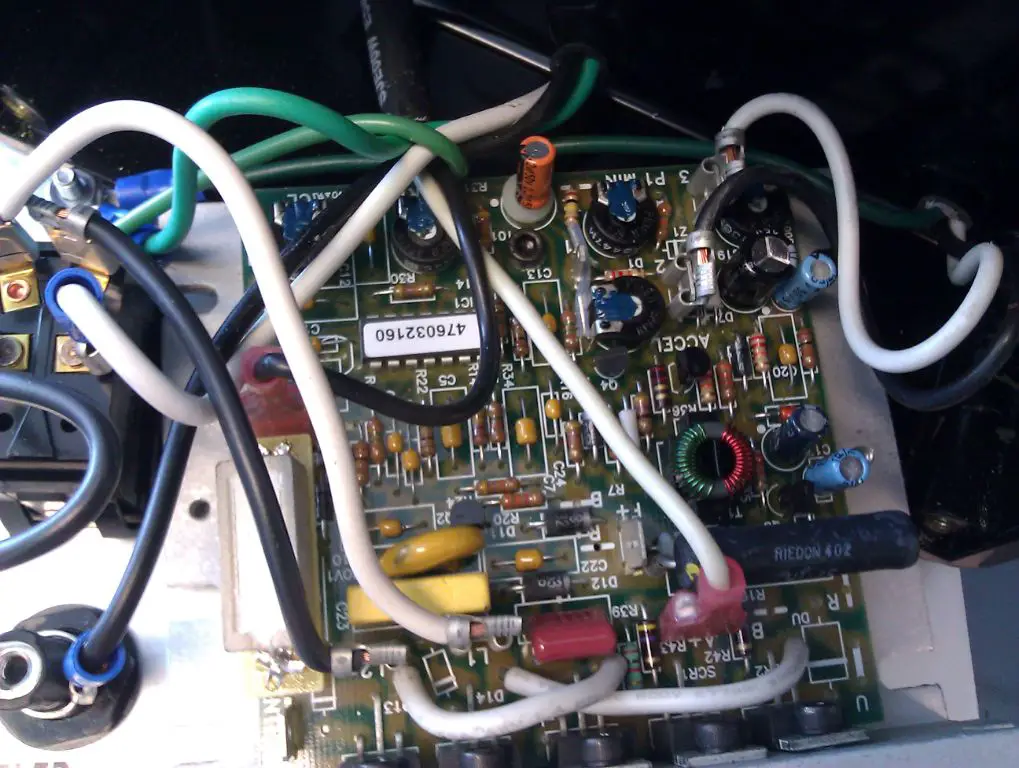

4. Connect the power wires from the motor to the power source, either directly to wall power or to a foot pedal switch. Consult a wiring diagram for proper connections.

5. Some disassembly of the wheel head may be required to fully integrate the new motor. Reinstall any necessary covers or guards.

6. Test run the new motor at various speeds to verify smooth and wobble-free operation before using the wheel for pottery work. Make any adjustments to alignment or tension as needed.

Refer to online videos such as Replacing the motor on your clay boss wheel- Episode 132 for visual guidance. Take proper safety precautions when working with electrical and mechanical components.

Conclusion

When choosing a pottery wheel motor, the most important factors to consider are power, variable speed control, noise level, maintenance needs, and cost. Optimal power will allow you to center clay even at high speeds without the motor bogging down. Variable speed control gives you flexibility and control for different types of projects and techniques. A quieter motor will allow you to focus on your work without distraction. Low maintenance motors require less cleaning and lubrication. And finding the right balance between features and price is key for most beginner and intermediate potters.

Final tips for choosing the right pottery wheel motor include: test driving different models to get a feel for power and speed control, reading reviews to understand real-world noise levels, researching maintenance schedules, and setting a budget but being willing to spend more for quality that will last. With some upfront research and testing, you’ll be able to find the ideal motor for your pottery wheel and style of working.